Description:

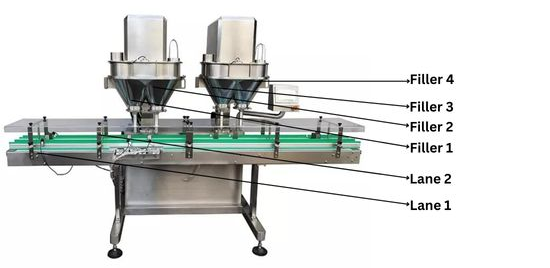

The dosing and filling machine with four auger heads is a compact model that takes up little space and fills four times faster than a single auger head. This machine is a solution for fulfilling the needs of a production line. It is controlled by a centralized system. Each lane has two filling heads, each capable of performing two independent fillings. A horizontal screw conveyor with two outlets would feed materials into the two auger hoppers.

Working Principle:

-Filler 1 and Filler 2 are in Lane 1.

-Filler 3 and Filler 4 are in Lane 2.

-Four fillers work together to achieve four times capacity than single filler.

This machine can measure, and fill powdered and granular materials. It includes two sets of twin filling heads, an independent motorized chain conveyor mounted on a sturdy, stable frame base, and all the accessories needed to move and position containers for filling, dispense the required amount of product, and quickly move the filled containers away to other equipment in your line. It works best with fluidic or low-fluidity materials such as milk powder, albumen powder, and others.

Composition:

Application:

Regardless of the application, it can help a wide range of industries in many ways.

Food Industry - milk powder, protein powder, flour, sugar, salt, oat flour, etc.

Pharmaceutical Industry – aspirin, ibuprofen, herbal powder, etc.

Cosmetic Industry – face powder, nail powder, toilet powder, etc.

Chemical Industry – talcum powder, metal powder, plastic powder, etc.

Special Features:

1. The structure was constructed of stainless steel.

2. The split hopper was easy to clean without the use of tools.

3. The servo motor's turning screw.

4. A PLC, a touch screen, and a weighing module provide control.

5. Only 10 sets of product parameter formulas should be saved for future use.

6. When the auger parts are replaced, it can handle materials ranging from super thin powder to granules.

7. Include a height-adjustable handwheel.

Specification:

| Station | Automatic Dual Heads Linear Auger Filler |

| Dosing Mode | Directly dosing by auger |

| Filling Weight | 500kg |

| Filling Accuracy | 1 - 10g,±3-5%; 10 - 100g, ≤±2%;100 – 500g, ≤±1% |

| Filling Speed | 100 – 120 bottles per min |

|

Power supply |

3P AC208-415V 50/60Hz |

| Air Supply | 6 kg/cm2 0.2m3/min |

| Total Power | 4.17 kw |

| Total Weight | 500kg |

| Overall Dimension | 3000×940×1985mm |

| Hopper Volume | 51L*2 |

Configuration:

|

Name |

Model Specification | PRODUCING AREA/Brand |

| HMI |

|

Schneider |

| Emergency switch |

|

Schneider |

| Contactor | CJX2 1210 | Schneider |

| Heat relay | NR2-25 | Schneider |

| Circuit breaker |

|

Schneider |

| Relay | MY2NJ 24DC | Schneider |

| Photo sensor | BR100-DDT | Autonics |

| Level sensor | CR30-15DN | Autonics |

| Conveyor motor | 90YS120GY38 | JSCC |

| Conveyor reducer | 90GK(F)25RC | JSCC |

| Air cylinder | TN16×20-S, 2units | AirTAC |

| Fiber | RiKO FR-610 | Autonics |

| Fiber receiver | BF3RX | Autonics |

Details: (Strong Points)

Hopper

The hopper's full stainless steel 304/316 hopper is food grade, easy to clean, and has a high-level appearance.

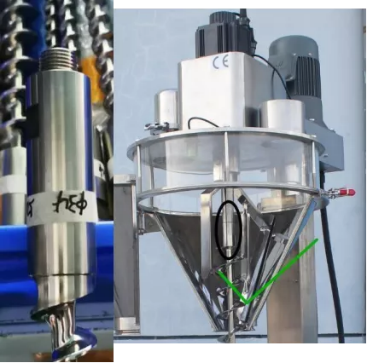

Screw Type

There are no gaps for a powder to hide inside, and it is simple to clean.

The Design

Complete welding, including the hopper edge and is simple to clean.

The Entire Machine

The entire machine, including the base and motor holder, is made of SS304, which is stronger and of higher quality.

Hand-wheel

It is appropriate for filling bottles/bags of varying heights. Turn the hand wheel to raise and lower the filler. Our holder is thicker and stronger than others.

Interlock Sensor

If the hopper is closed, the sensor detects it. When the hopper is open, the machine automatically stops to prevent the operator from being injured by turning the auger.

4 Filler Heads

Two pairs of twin fillers (four fillers) work together to achieve four times the capacity of a single head.

Augers and Nozzles of Various Sizes

The auger filler principle states that the amount of powder brought down by turning the auger one circle is fixed. As a result, different auger sizes can be used in different filling weight ranges to achieve greater accuracy and save time. Each size auger has a corresponding size auger tube. Día, for example. The 38mm screw is suitable for filling 100g-250g containers.

Cup Size and Filling Range

|

Order |

Cup |

Inner Diameter |

Outer Diameter |

Filling Range |

|

1 |

8# |

8mm |

12mm |

|

|

2 |

13# |

13mm |

17mm |

|

|

3 |

19# |

19mm |

23mm |

5-20g |

|

4 |

24# |

24mm |

28mm |

10-40g |

|

5 |

28# |

28mm |

32mm |

25-70g |

|

6 |

34# |

34mm |

38mm |

50-120g |

|

7 |

38# |

38mm |

42mm |

100-250g |

|

8 |

41# |

41mm |

45mm |

230-350g |

|

9 |

47# |

47mm |

51mm |

330-550g |

|

10 |

53# |

53mm |

57mm |

500-800g |

|

11 |

59# |

59mm |

65mm |

700-1100g |

|

12 |

64# |

64mm |

70mm |

1000-1500g |

|

13 |

70# |

70mm |

76mm |

1500-2500g |

|

14 |

77# |

77mm |

83mm |

2500-3500g |

|

15 |

83# |

83mm |

89mm |

3500-5000g |

Installation and Maintenance

-When you receive the machine, all you must do is unpack the crates and connect the machine's electricity power, and the machine will be ready to use. It is very simple to program machines to work for any user.

-Once every three or four months, add a small amount of oil. After filling materials, clean the auger filler's four heads.

Can Connect with Other Machines

4 heads auger filler can be combined with various machines to create a new working mode to meet varying production requirements.

It is compatible with other equipment in your lines, such as cappers and labelers.

Production and Processing

Our Team

Certificates

Service & Qualifications

■ TWO YEAR warranty, ENGINE THREEYEARS warranty, life-long service (Warranty service will be honored if the damage is not caused by human or improper operation)

■ Provide accessory parts in favorable price

■ Update configuration and program regularly

■ Respond to any question in 24 hours