5 different types of auger powder filling machine

1.Desktop table

This desktop table type of auger powder filling machine is the smallest model for laboratory. This type is suitable for normal speed filling. It is operated manually by placing the bottle on the plate under the filler and moves away the bottle after filling. It can handle bottle or pouch package. The sensor can be chosen between tuning fork sensor and photoelectric sensor.

Specification

|

Model |

TP-PF-A10 |

|

Control system |

PLC & Touch Screen |

|

Hopper |

11L |

|

Packing Weight |

1-50g |

|

Weight dosing |

By auger |

|

Weight Feedback |

By off-line scale (in picture) |

|

Packing Accuracy |

≤ 100g, ≤±2% |

|

Filling Speed |

40 – 120 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

|

Total Power |

0.84 KW |

|

Total Weight |

90kg |

|

Overall Dimensions |

590×560×1070mm |

2.Semi-auto type

This semi-auto type of auger powder filling machine is suitable for normal speed filling. It is operated manually by placing the bottle on the plate under the filler and moves away the bottle after filling. It can handle bottle or pouch package. The sensor can be chosen between tuning fork sensor and photoelectric sensor.

Specification

|

Model |

TP-PF-A11 |

TP-PF-A11S |

TP-PF-A14 |

TP-PF-A14S |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

||

|

Hopper |

25L |

50L |

||

|

Packing Weight |

1 - 500g |

10 - 5000g |

||

|

Weight dosing |

By auger |

By load cell |

By auger |

By load cell |

|

Weight Feedback |

By off-line scale (in picture) |

Online weight feedback |

By off-line scale (in picture) |

Online weight feedback |

|

Packing Accuracy |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

||

|

Filling Speed |

40 – 120 times per min |

40 – 120 times per min |

||

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

||

|

Total Power |

0.93 KW |

1.4 KW |

||

|

Total Weight |

160kg |

260kg |

||

|

Overall Dimensions |

800×790×1900mm |

1140×970×2200mm |

||

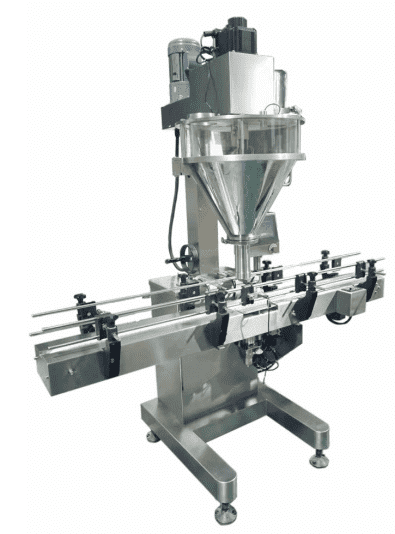

3.Automatic liner type

This automatic liner type of auger powder filling machine is suitable for bottle filling and dosing. The conveyor automatically moves the bottle in and the bottle stopper holds back bottles so that the bottle holder can raise the bottle under the filler. After the bottles have been filled, the conveyor automatically moves them forward. It can handle different bottle sizes on one machine and it is ideal for users that have multiple packaging dimensions. Two sensors are available the fork sensor and photoelectric sensor.

Specification

|

Model |

TP-PF-A21 |

TP-PF-A22 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

25L |

50L |

|

Packing Weight |

1 - 500g |

10 - 5000g |

|

Weight dosing |

By auger |

By auger |

|

Weight Feedback |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Packing Accuracy |

40 – 120 times per min |

40 – 120 times per min |

|

Filling Speed |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

1.2 KW |

1.6 KW |

|

Total Weight |

160kg |

300kg |

|

Overall Dimensions |

1500×760×1850mm |

2000×970×2300mm |

4.Automatic rotary type

High-speed automatic rotary type is used to load powder into bottles. Since the bottle wheel can only take one diameter, this type of auger powder filling machine is best for customers who only have one or two diameter bottles. The speed and accuracy are, generally, greater than that of automatic liner type. Moreover, the automatic rotary type includes online weighing and rejection capabilities. The filler will fill powder according to the filling weight in actual time, and the rejection function will identify and remove unqualified weight. The machine cover is an optional.

Specification

|

Model |

TP-PF-A31 |

TP-PF-A32 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

35L |

50L |

|

Packing Weight |

1-500g |

10 - 5000g |

|

Weight dosing |

By auger |

By auger |

|

Container size |

Φ20~100mm ,H15~150mm |

Φ30~160mm ,H50~260mm |

|

Packing Accuracy |

≤ 100g, ≤±2% 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% ≥500g,≤±0.5% |

|

Filling Speed |

20 – 50 times per min |

20 – 40 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

1.8 KW |

2.3 KW |

|

Total Weight |

250kg |

350kg |

|

Overall Dimensions |

1400*830*2080mm |

1840×1070×2420mm |

5.Big bag type

This big bag type is designed for fine powders that discharge a fine dust and require precise packing. This type of machine can perform measurements, two-filling, up-down work and more. The following is based on the weight sensor's feedback output. It's perfect for filling fine powders such as additives, carbon powder, fire extinguisher dry powder, and other fine powders that require precise packing.

Specification

|

Model |

TP-PF-B11 |

TP-PF-B12 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

Quick disconnecting hopper 70L |

Quick disconnecting hopper 100L |

|

Packing Weight |

100g-10kg |

1-50kg |

|

Dosing mode |

With online weighing; Fast and slow filling |

With online weighing; Fast and slow filling |

|

Packing Accuracy |

100-1000g, ≤±2g; ≥1000g,±0.2% |

1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

|

Filling speed |

5 – 30 times per min |

2– 25 times per min |

|

Power supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total power |

2.7 KW |

3.2 KW |

|

Total weight |

350kg |

500kg |

|

Overall Dimensions |

1030×850×2400mm |

1130×950×2800mm |

Configurations List of Big Bag Type

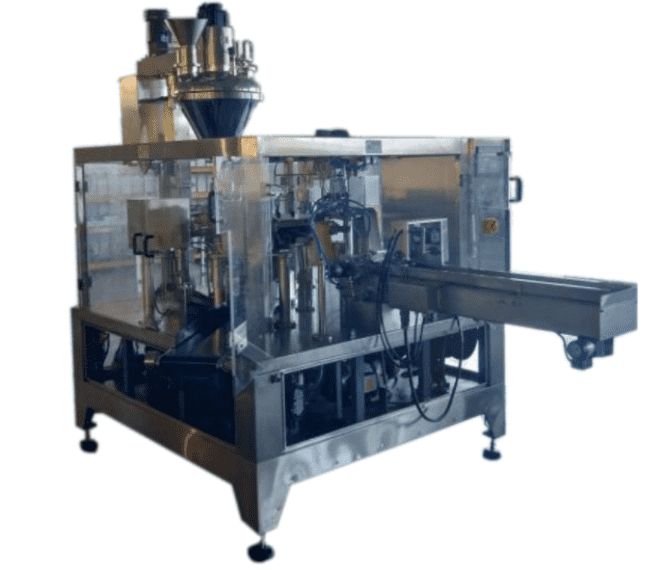

Powder packing system

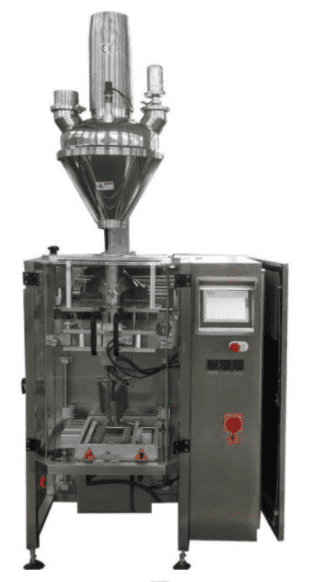

When the auger powder filling machine is combined with the packing machine, a powder packing machine is formed. It can be used in combination with a roll film sachet filling and sealing machine, as well as a mini doypack packing machine, rotary pouch packing machine, or premade pouch packing machine.

Special Features of auger powder filling machine

-Turning auger to make sure high filling accuracy.

- With PLC control and touch screen display which is easy to operate.

- The auger is driven by a servo motor to provide consistent performance.

-The hopper can be quickly disconnected and cleaned without the use of any tools.

-The entire machine is made of stainless steel 304.

-The online weighing function and material proportion tracking eliminate the challenge of filling weight changes due to material density changes.

- Keep a total of 20 sets of recipes in the application for future use.

- Using a new auger to pack a variety of items with varying weights, ranging from fine powder to particles.

- With the ability to reject weight that is not up to standard.

-Multi language interface.

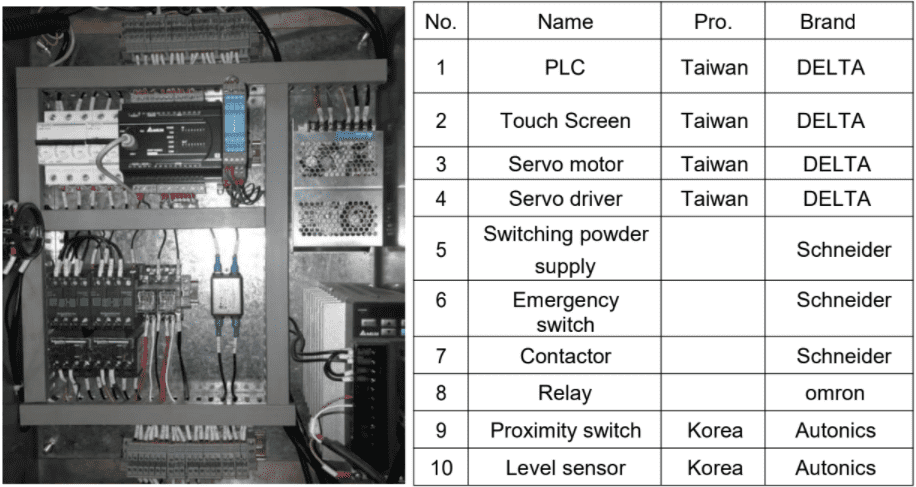

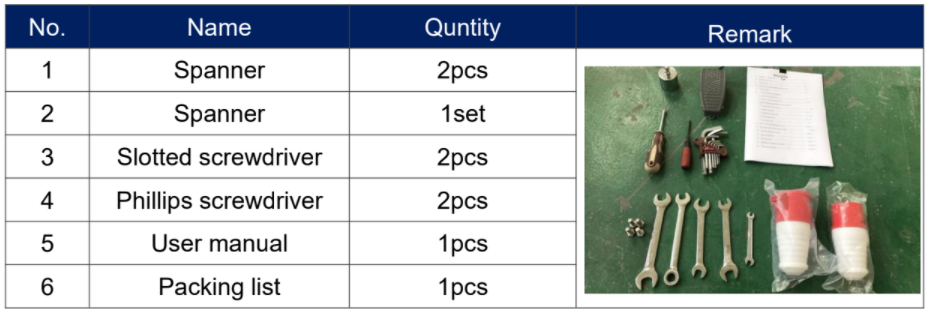

Configuration List

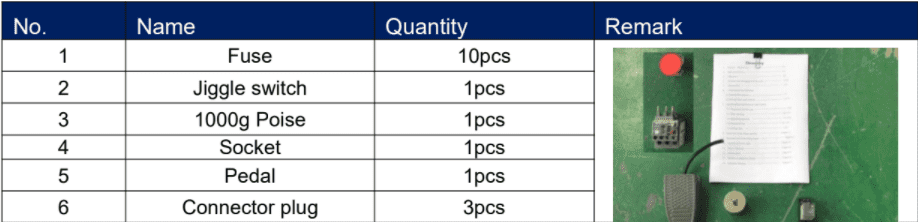

Accessories

Tool Box

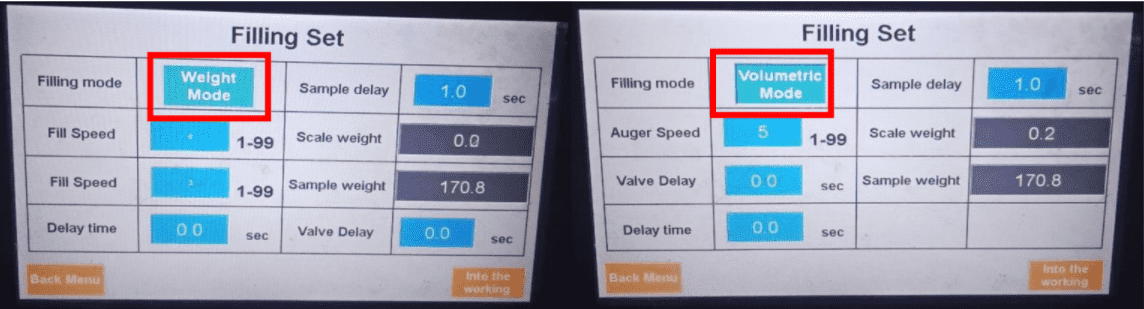

Weight mode

Under the filling plate is a load cell that measures the filling weight in real time. To achieve 80% of the required filling weight, the first filling is quick and mass filling. The second filling is slow and precise, supplementing the remaining 20% according to the weight of the first filling. The accuracy of the weight mode is higher, but the speed is slower.

Auger powder filling machine information

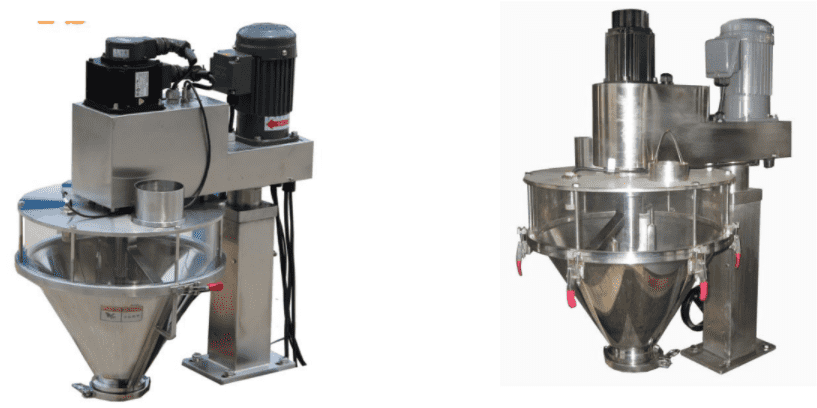

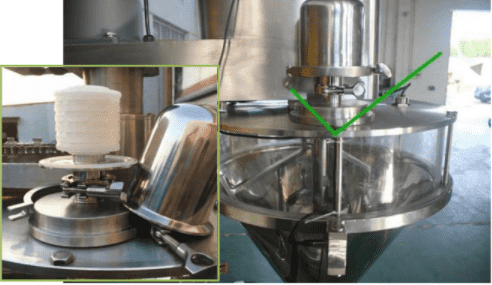

● Optional Hopper

Half open hopper

This level split hopper is easy to clean and open.

Hanging hopper

Combine hopper is fit for fine powder and there is no gap at lower part of hopper.

● Filling mode

Weight and volume modes are changeable.

Volume mode

The powder volume reduced by turning the screw one round is fixed. The controller will figure out how many turns the screw needs to make in order to reach the desired filling weight.

Auger powder filling machine fixing way

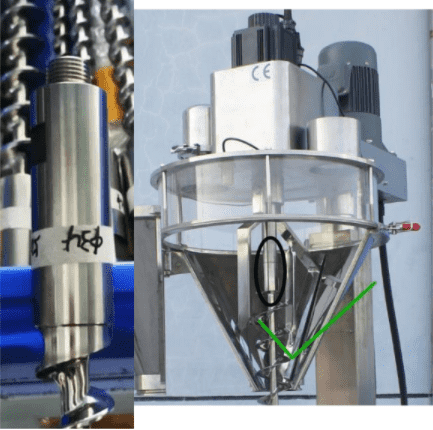

Screw type

There are no gaps inside where powder might hide, and it's easy to clean.

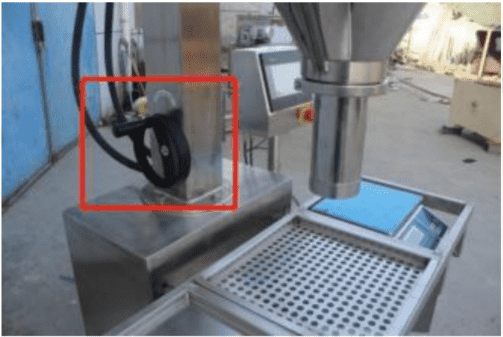

Auger powder filling machine hand wheel

It is suitable to fill bottles and bags of different heights. To raise and lower the filler by turning the hand wheel. And our holder is thicker and more durable.

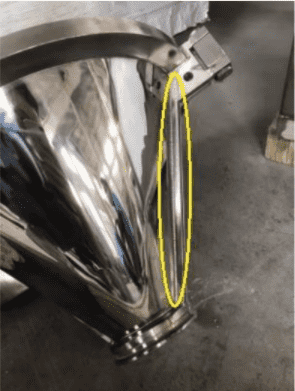

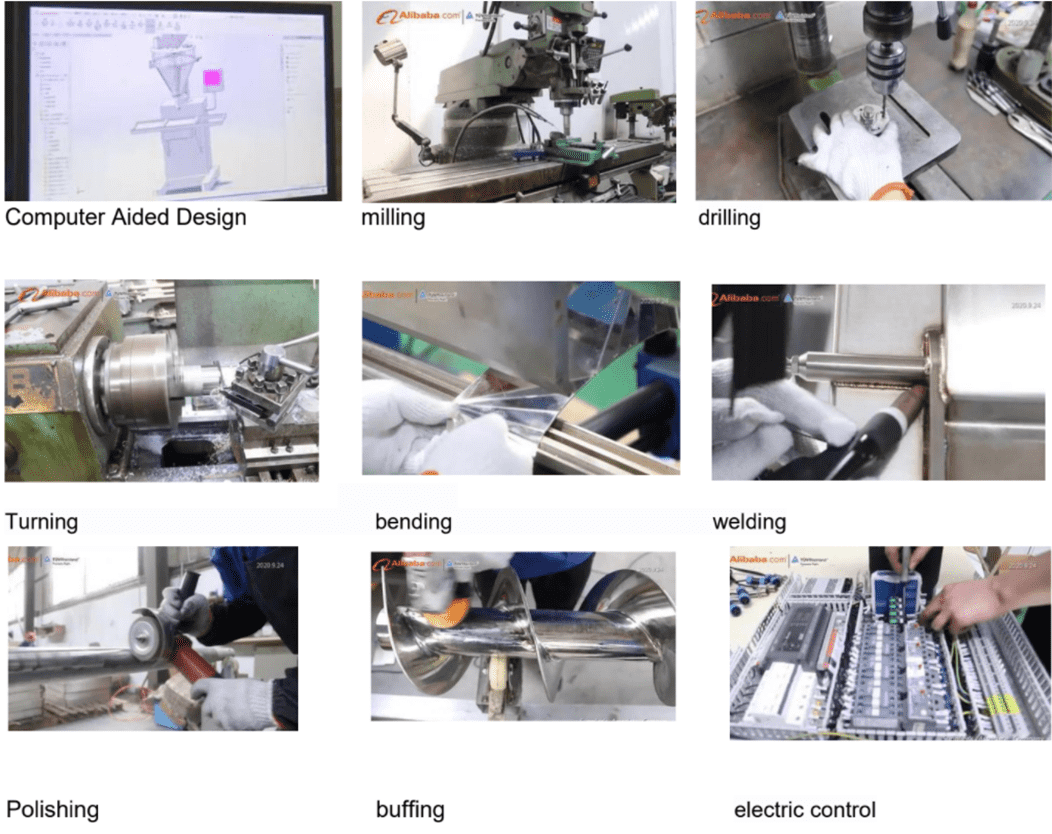

Auger powder filling machine processing

Full welded including the hopper edge and easy to clean.

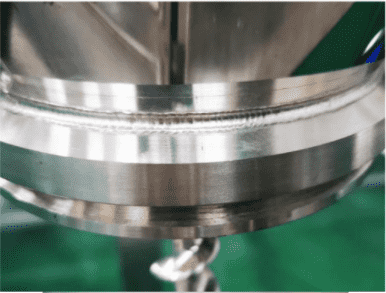

Auger powder filling machine motor base

The entire machine, including the base and motor holder, is made of SS304, which is durable and high material.

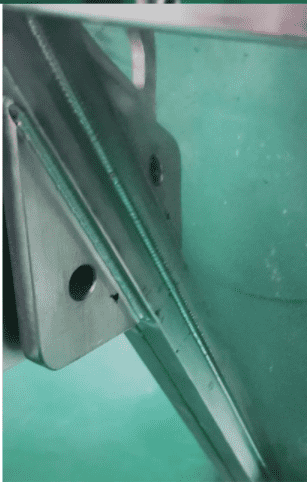

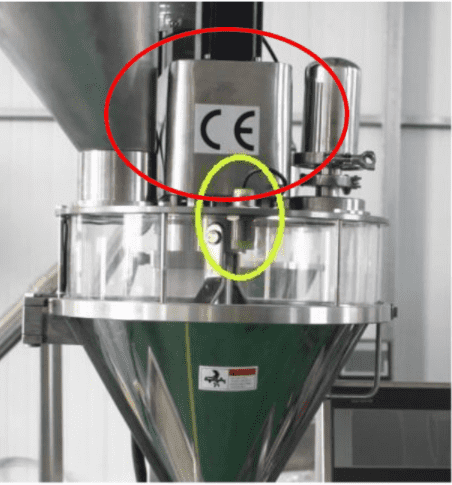

Auger powder filling machine air outlet

This special design is for preventing dust to fall into the hopper. It is easy to clean and high level.

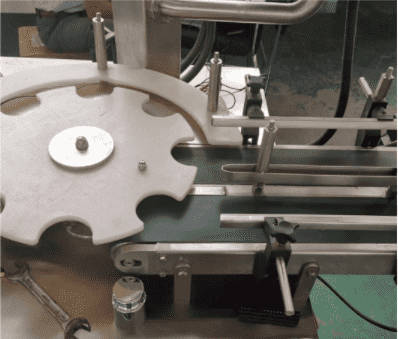

Auger powder filling machine two output belt

One belt collects weight qualified bottles, while the other belt collects weight unqualified bottles.

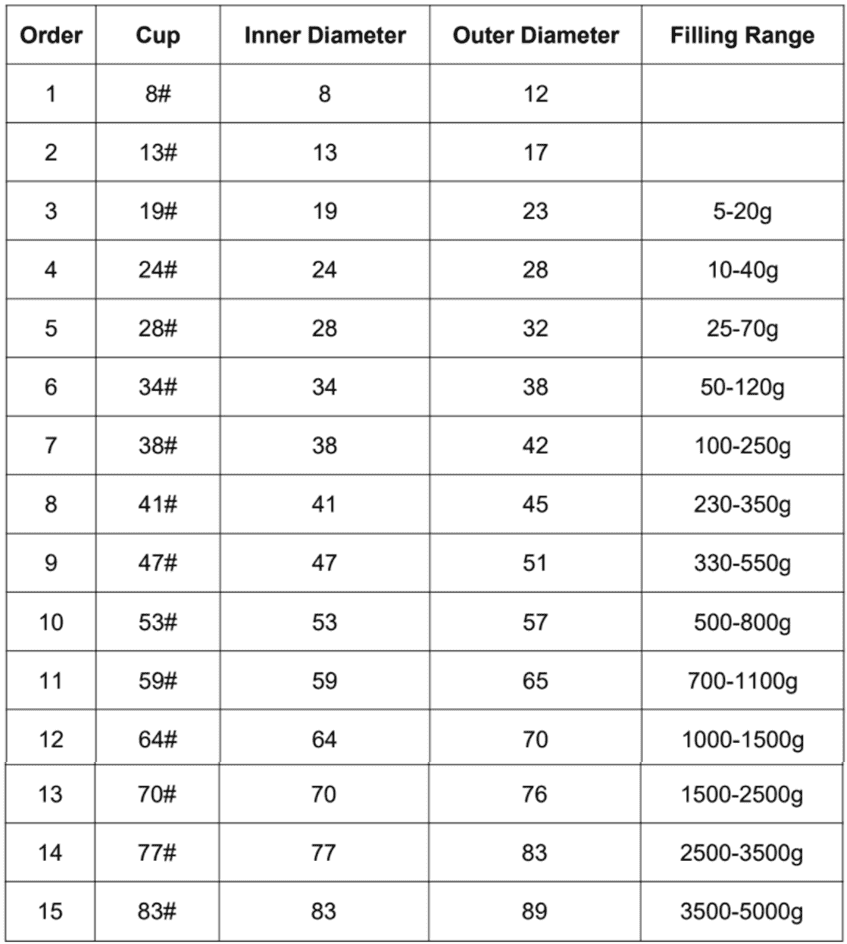

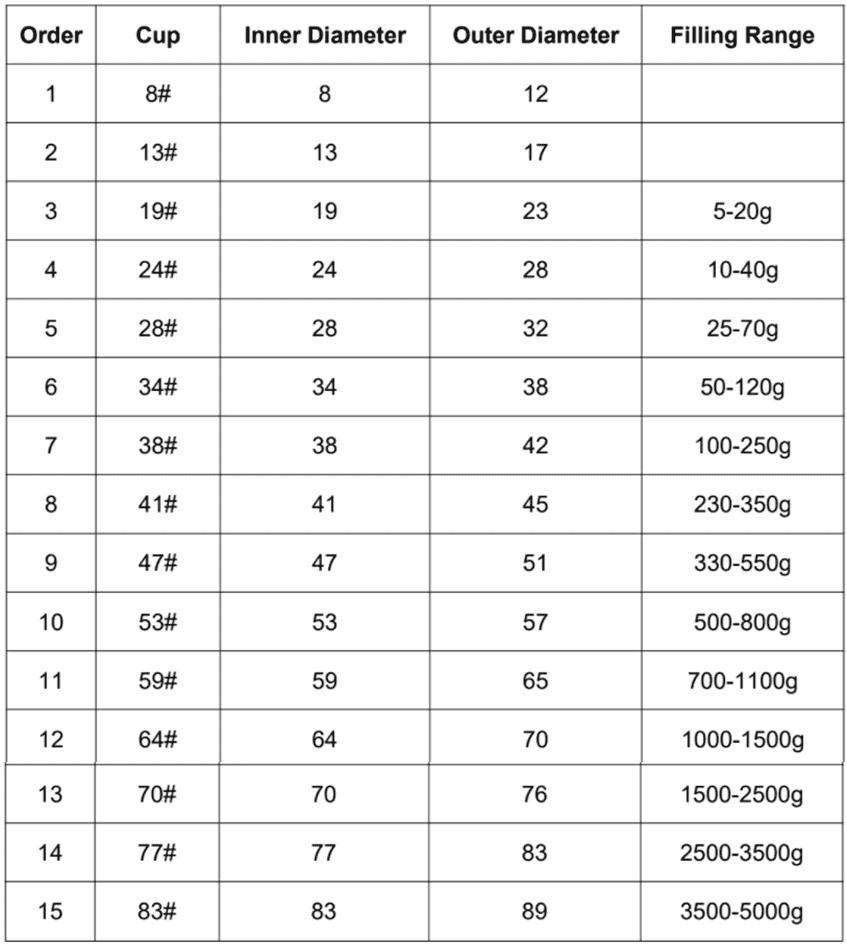

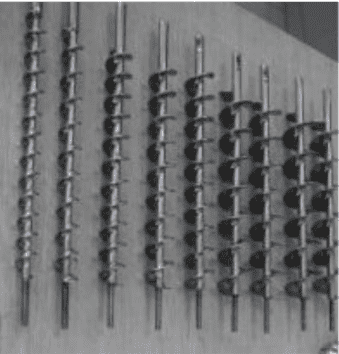

Auger powder filling machine different sizes metering auger and filling nozzles

To achieve improved accuracy and save time, different sizes of auger can be used in different filling weight ranges.

One size screw is suitable for one weight range in order to ensure filling precision; for example, a diameter 38mm screw is good for filling 100g-250g.

Auger powder filling machine sizes and related filling weight ranges

Cup Sizes and Filling Range

If you're not sure what size auger you need, please contact us and we will help you choose the right one.

Related Machines:

Screw feeder work for auger powder filling machine Bag sealing machine

Dust-collector work for auger powder filling machine

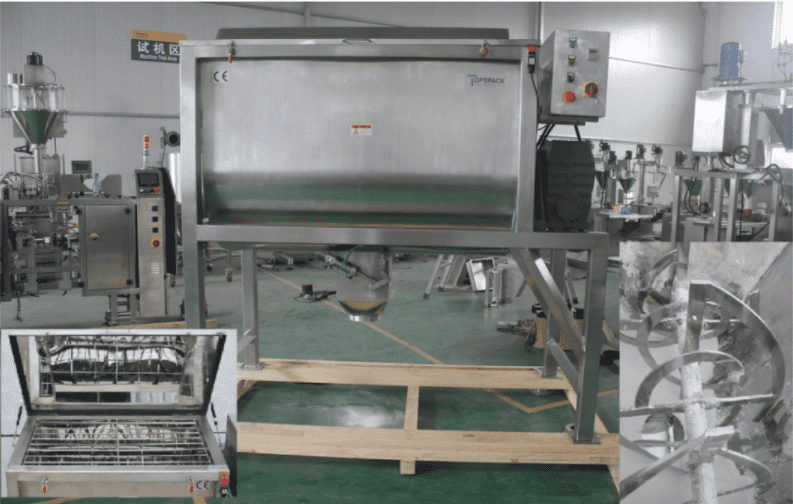

Ribbon Mixer

Processing of auger powder filling machine

Factory Show

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur