General Description

This machine provides a comprehensive and affordable solution for your filling production line needs, catering to the measuring and filling of both powders and granules. It is composed of a Filling Head, an independently motorized chain conveyor mounted on a sturdy and stable frame base, as well as all required accessories for dependable container movement and positioning during the filling process. It is particularly suitable for materials with fluid or low-fluidity properties, such as milk powder, egg white powder, pharmaceuticals, condiments, powdered beverages, white sugar, dextrose, coffee, agricultural pesticides, granular additives, and more.

Video

Features

● Lathing auger screw to guarantee the precise filling accuracy

● PLC control and touch screen display

● Servo motor drives screw to guarantee stable performance

● Quick disconnecting hopper could be washed easily without tools

● Can be setting to semi-auto filling by pedal switch or auto filling

● Full stainless steel 304 material

● weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials’ density change.

● Save 20 sets of formula inside the machine for later use

● Replacing the auger parts, different products ranging from fine powder to granule and different weight can be packed

● Multi language interface

Specification

|

Model |

TP-PF-A21 |

TP-PF-A22 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

Quick disconnecting hopper 45L |

Quick disconnecting hopper 50L |

|

Packing Weight |

10 - 5000g |

10-5000g |

|

Dosing mode |

Directly dosing by auger |

Directly dosing by auger |

|

Packing Accuracy |

≤ 500g, ≤±1%; >500g, ≤±0.5% |

≤500g, ≤±1%; >500g, ≤±0.5% |

|

Filling Speed |

15 – 40 times per min |

15 – 40 times per min |

|

Air supply |

6 kg/cm2 0.05m3/min |

6 kg/cm2 0.05m3/min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

1.6 KW |

1.6 KW |

|

Total Weight |

300kg |

300kg |

|

Overall Dimensions |

2000×970×2030mm |

2000×970×2300mm |

Configuration List

| No. |

Name |

Specification |

Pro. |

Brand |

|

1 |

Stainless steel |

SUS304 |

China |

|

|

2 |

Touch Screen |

|

Taiwan |

Panel Master |

|

3 |

Servo motor |

TSB13102B-3NHA |

Taiwan |

TECO |

|

4 |

Servo driver |

ESDA40C-TSB152B27T |

Taiwan |

TECO |

|

5 |

Agitator motor |

0.4kw,1:30 |

Taiwan |

CPG |

|

6 |

Switch |

|

Shanghai |

|

|

7 |

Emergency switch |

|

|

Schneider |

|

8 |

Filter |

|

|

Schneider |

|

9 |

Contactor |

|

Wenzhou |

CHINT |

|

10 |

Hot relay |

|

Wenzhou |

CHINT |

|

11 |

Fuse seat |

RT14 |

Shanghai |

|

|

12 |

Fuse |

RT14 |

Shanghai |

|

|

13 |

Relay |

|

|

Omron |

|

14 |

Switching power supply |

|

Changzhou |

Chenglian |

|

15 |

Proximity switch |

BR100-DDT |

Korea |

Autonics |

|

16 |

Level sensor |

|

Korea |

Autonics |

| Accessories |

|

|

|

|

|

No. |

Name |

Quntity |

Remark |

|

|

1 |

Fuse |

10pcs |

|

|

|

2 |

Jiggle switch |

1pcs |

|

|

|

3 |

1000g Poise |

1pcs |

|

|

|

4 |

Socket |

1pcs |

|

|

|

5 |

Pedal |

1pcs |

|

|

|

6 |

Connector plug |

3pcs |

|

|

| Accessory tools : |

|

|

|

|

|

No. |

Name |

Quntity |

|

Remark |

|

1 |

Spanner |

2pcs |

|

|

|

2 |

Spanner |

1set |

|

|

|

3 |

Slotted screwdriver |

2pcs |

|

|

|

4 |

Phillips screwdriver |

2pcs |

|

|

|

5 |

User manual |

1pcs |

|

|

|

6 |

Packing list |

1pcs |

|

|

Detailed Parts

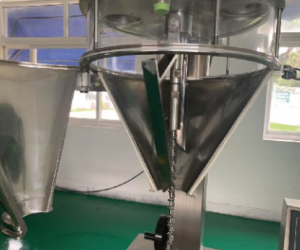

Hopper: Level split hopper. It is very easy to open hopper and it is also easy for cleaning.

The way to fix auger screw: Screw type The material will not be stock and easy for cleaning.

Processing: Fully welded materials, even Hopper's sides and it'easy to clean.

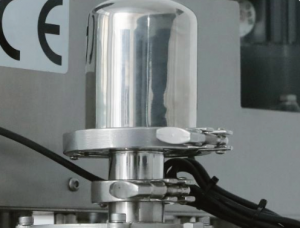

Air outlet: Stainless steel type, it is easy to clean and presentable.

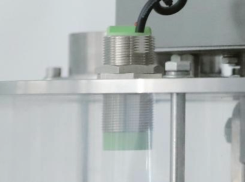

Level senor (autonics): it gives signal to loader when material lever is low, it does feeding automatically.

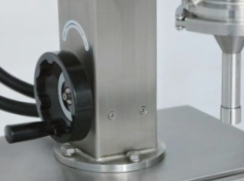

Handwheel: to adjust filler height to suit various bottle heights.

Leakproof acentic device: It is suitable for filling products with very good fluidity, such as, salt, white sugar etc.

8.Conveyor: For automatic moving bottles.

About Us

Shanghai Tops Group Co., Ltd is professional manufacturer for powder and granular packaging systems.

We specialize in the fields of designing, manufacturing, supporting and servicing a complete line of machinery for different kinds of powder and granular products, Our main target of working is to offer the products which are related to the food industry, agriculture industry, chemical industry, and pharmacy field and more.

We value our customers and are dedicated to maintaining relationships to ensure continued satisfaction and create win-win relationship. Let’s work hard altogether and make much greater success in the near future!

Factory Show

Our Certification