Video

Descriptive abstract for bottle sticker labeling machine

Bottle labeling machine is economical, independent and easy to operate. automatic bottle labeling machine is equipped with automatic teaching and programming touch screen. The built-in microchip stores different job Settings, and the conversion is quick and convenient.

■ Labeling self-adhesive sticker on top, flat or big radians surface of product.

■ Products Applicable: square or flat bottle, bottle cap, electrical components etc.

■ Labels Applicable: adhesive stickers in roll.

Key Features for automatic round bottle labeling machine

■ Labeling speed up to 200 CPM

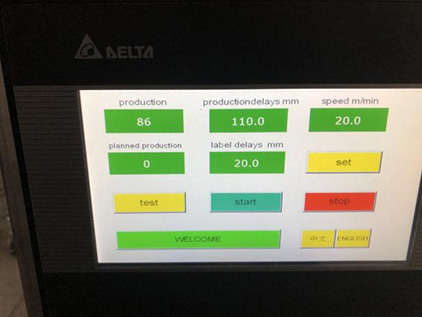

■ Touch Screen Control System with Job Memory

■ Simple Straight Forward Operator Controls

■ Full-set protecting device keep operation steady and reliable

■ On-Screen trouble shooting & Help Menu

■ Stainless steel Frame

■ Open Frame design, easy to adjust and change the label

■ Variable Speed with stepless motor

■ Label Count Down (for precise run of set number of labels) to Auto Shut Off

■ Automatic Labeling, work independently or connected to a production line

■ Stamping Coding Device is optional

Specifications for automatic labeling machine

|

Working direction |

Left → Right (or Right → Left) |

|

Bottle diameter |

30~100 mm |

|

Label width(max) |

130 mm |

|

Label length(max) |

240 mm |

|

Labeling Speed |

30-200 bottles/minute |

|

Conveyor speed(max) |

25m/min |

|

Power source & consumption |

0.3 KW, 220v, 1 Ph, 50-60HZ(Optional) |

|

Dimensions |

1600mm×1400mm×860 mm ( L × W × H ) |

|

Weight |

250kg |

Application

■ Cosmetic /personal care

■ Household chemical

■ Food & beverage

■ Nutraceuticals

■ Pharmaceutial

Major components of sticker labelling machine

|

Specifications |

Brand |

Manufactory |

|

HMI |

Touch screen (Delta) |

Delta Electronic |

|

PLC |

Mitsubishi |

Mitsubishi Electronic |

|

frequency converter |

Mitsubishi |

Mitsubishi Electronic |

|

Label puller motor |

Delta |

Delta Electronic |

|

Conveyor motor |

WANSHSIN |

Tai wan WANSHSIN |

|

Conveyor reducer |

WANSHSIN |

Tai wan WANSHSIN |

|

Label inspection sensor |

Panasonic |

Panasonic Corporation |

|

Bottle inspection sensor |

Panasonic |

Panasonic Corporation |

|

Fixed cylinder |

AirTAC |

AirTAC internation group |

|

Fixed solenoid valve |

AirTAC |

AirTAC internation group |

Details

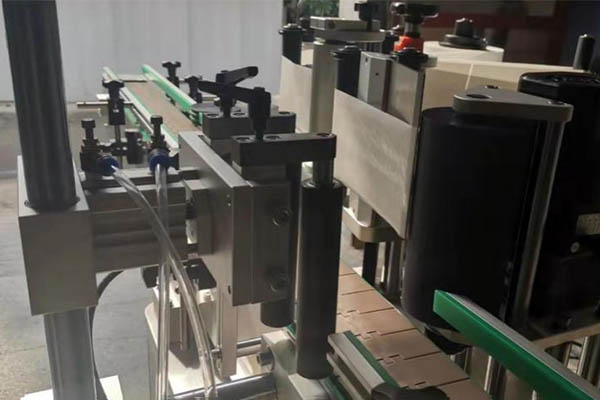

The bottle separator can control the bottle conveying speed by adjusting the separator speed, and the operation is simple and convenient.

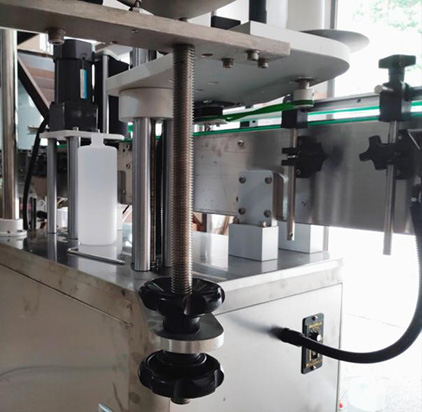

The hand-wheel can rise and lower the whole labeling table.

The screw stay bar can hold the whole labeling table and make the table on the same level.

World famous brand electrical parts.

The labeling device controlled by the air cylinder.

The step motor can be customized into servo motor.

The touch screen is simple and easy to operate.

Factory view