Best High Quality Powder Capsule Filling Machine Pricelist – Powder Filling Machine – Shanghai Tops Detail:

Video

Semi-automatic

Descriptive abstract

Semi automatic powder filling machine is a compact model applied to dose all kinds of dry powder both free flow and non-free flow powder into bags/bottles/cans/jars/etc. The filling was controlled by PLC and servo drive system featured with high speed and good accuracy.

Main features

1. Fully Stainless-Steel Structure, quick disconnect hopper or split hopper, easy to clean.

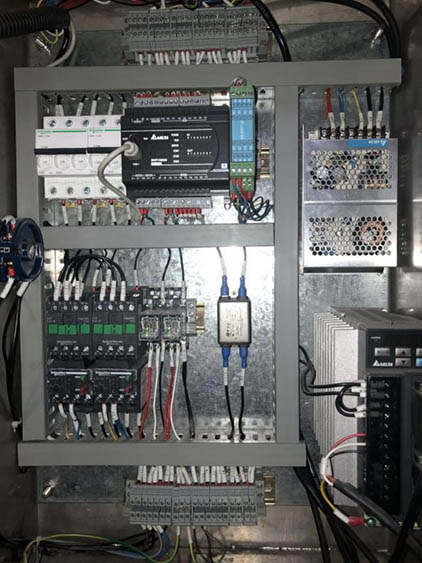

2. With Delta PLC and touch screen and Servo Motor /Driver

3. Servo motor and servo drive control the filling auger.

4. With 10 Product Receipt Memory.

5. Change the auger dosing tool, it could fill various kind of material including the powder to granule.

Current design manual powder filling machine

TP-PF-A10

TP-PF-A11/A14

TP-PF-A11/A14S

Parameters

|

Model |

TP-PF-A10 |

TP-PF-A11 |

TP-PF-A11S |

TP-PF-A14 |

TP-PF-A14S |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

||

|

Hopper |

11L |

25L |

50L |

||

|

Packing Weight |

1-50g |

1 – 500g |

10 – 5000g |

||

|

Weight dosing |

By auger |

By auger |

By load cell |

By auger |

By load cell |

|

Weight Feedback |

By off-line scale (in picture) |

By off-line scale (in picture) |

Online weight feedback |

By off-line scale (in picture) |

Online weight feedback |

|

Packing Accuracy |

≤ 100g, ≤±2% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

||

|

Filling Speed |

40 – 120 times per min |

40 – 120 times per min |

40 – 120 times per min |

||

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

||

|

Total Power |

0.84 KW |

0.93 KW |

1.4 KW |

||

|

Total Weight |

90kg |

160kg |

260kg |

||

|

Model |

TP-PF-A11N |

TP-PF-A11NS |

TP-PF-A14N |

TP-PF-A14NS |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

||

|

Hopper |

25L |

50L |

||

|

Packing Weight |

1 – 500g |

10 – 5000g |

||

|

Weight dosing |

By auger |

By load cell |

By auger |

By load cell |

|

Weight Feedback |

By off-line scale (in picture) |

Online weight feedback |

By off-line scale (in picture) |

Online weight feedback |

|

Packing Accuracy |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

||

|

Filling Speed |

40 – 120 times per min |

40 – 120 times per min |

||

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

||

|

Total Power |

0.93 KW |

1.4 KW |

||

|

Total Weight |

160kg |

260kg |

||

High-level design semi automatic auger powder filling machine

Automatic linear model

Current design

Descriptive abstract

Bottles straight-feed system combined with powder vertical-feed system, when empty bottle coming to the filling station will be stopped by the indexing stop cylinder (Gating system) after the preset time delay the filling will start automatically, when preset pulse number set powder were released to the bottles then stop cylinder will draw back and filled bottle move to next station.

Main features

1. This is an automatic powder filling machine for can/bottles, designed for metering, and filling various dry powder into different rigid containers: Can/Bottle/Jar etc.

2. Auger powder filling machine provides powder metering and filling functions.

3. Bottles and cans are introduced by conveyor belt combined with gating system.

4. There is a photo eye sensor for bottles detection to achieve bottle-fill, no-bottle no-fill.

5. Automatic bottle positioning-filling-releasing, optional vibration and elevation.

6. Featured with compact design, stable performance, easy to operate and good cost performance!

Parameters

|

Model |

TP-PF-A10 |

TP-PF-A21 |

TP-PF-A22 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

11L |

25L |

50L |

|

Packing Weight |

1-50g |

1 – 500g |

10 – 5000g |

|

Weight dosing |

By auger |

By auger |

By auger |

|

Packing Accuracy |

≤ 100g, ≤±2% |

≤ 100g, ≤±2%; 100 –500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Filling Speed |

40 – 120 times per min |

40 – 120 times per min |

40 – 120 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

0.84 KW |

1.2 KW |

1.6 KW |

|

Total Weight |

90kg |

160kg |

300kg |

|

Overall Dimensions |

590×560×1070mm |

1500×760×1850mm |

2000×970×2300mm |

High level design

|

Model |

TP-PF-A10N |

TP-PF-A21N |

TP-PF-A22N |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

11L |

25L |

50L |

|

Packing Weight |

1-50g |

1 – 500g |

10 – 5000g |

|

Weight dosing |

By auger |

By auger |

By auger |

|

Packing Accuracy |

≤ 100g, ≤±2% |

≤ 100g, ≤±2%; 100 –500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Filling Speed |

40 – 120 times per min |

40 – 120 times per min |

40 – 120 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

0.84 KW |

1.2 KW |

1.6 KW |

|

Total Weight |

90kg |

160kg |

300kg |

|

Overall Dimensions |

590×560×1070mm |

1500×760×1850mm |

2000×970×2300mm |

Automatic rotary powder filling machine

Descriptive abstract

Powder filling equipment is suitable for dry syrup, talcum, spices powder, flour Free Flowing Powders Chemicals, Pharmaceutical Powers, Food & Beverages, Cosmetics powder, Pesticides Powder, etc.

Main features

1. Total compact design model. Split hopper for easy clean.

2. powder bottle filling machine is made of S.S.304 and easily removable for maintenance changeover.

3. Delta PLC and Touch screen, easy to operate.

4. NO BOTTLE, NO FILL” System eliminates wastage of costly powder.

5. Filling controlled by servo system with adjustable speed and high accuracy outcome.

6. With inline filled cans check weigher and reject conveyor to assure high accuracy output.

7. Different size star wheel to accommodate different container size, featured with easy maintenance and changeover.

|

Model |

TP-PF-A31 |

TP-PF-A32 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

25L |

50L |

|

Packing Weight |

1 – 500g |

10 – 5000g |

|

Weight dosing |

By auger |

By auger |

|

Packing Accuracy |

≤ 100g, ≤±2%; 100 –500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Filling Speed |

40 – 120 times per min |

40 – 120 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

1.2 KW |

1.6 KW |

|

Total Weight |

160kg |

300kg |

|

Overall Dimensions |

1500×760×1850mm |

2000×970×2300mm |

Automatic double head dry powder filling machine

Descriptive abstract

Automatic double head auger type powder filling machine is capable of dispensing powder into round-shaped rigid container at line speeds up to 100 bpm, Multi-stages filling integrated with check weighing and reject system which provides precise weight control to save expensive product give-away and featured with high output and high accuracy. Milk powder filling machine is widely used in milk powder production line with good outcome and stable performance.

Main features

1. Four-stages filling integrated with inline check weigher and reject system: High output, high accuracy.

2. All parts and assemblies encountering powder are made of S.S.304 and easily removable for maintenance changeover.

3. Delta PLC and touch screen, easy to operate.

4. NO BOTTLE, NO FILL” System eliminates wastage of costly powder.

5. Conveyor driving is through High quality Gear motor with stable performance.

6. High-response weighing system ensures high canning speed and high accuracy.

7. Pneumatic bottle indexing system relates to auger rotation, which eliminates chances of bottle transfer before completion of filling operation.

8. Dust collect device, which could connect with vacuum cleaner. Keep the clean workshop environment.

Parameters

|

Dosing mode |

Double lines dual filler filling with online weighing |

|

Filling Weight |

100 – 2000g |

|

Container Size |

Φ60-135mm; H 60-260mm |

|

Filling Accuracy |

100-500g, ≤±1g; ≥500g,≤±2g |

|

Filling Speed |

Above 100 cans/min(#502),Above 120 cans/min(#300 ~ #401) |

|

Power Supply |

3P AC208-415V 50/60Hz |

|

Total Power |

5.1 kw |

|

Total Weight |

650kg |

|

Air Supply |

6kg/cm 0.3cbm/min |

|

Overall Dimension |

2920x1400x2330mm |

|

Hopper Volume |

85L(Main) 45L (Assist) |

Big powder bag filling machine

Descriptive abstract

This model of manual dry filling machine is designed mainly for the fine powder which easily to spout dust and high-accuracy packing requirement. Based on the feedback sign given by below weight sensor, this machine does measure, two-filling, and up-down work, etc. Powder weighing and filling machine is especially suitable for filling additives, carbon powder, dry powder of fire extinguisher, and other fine powder which needs high packing accuracy.

Main features

1. Servo motor drives auger, seperate motor for stir.

2. With Siemens PLC, Teco servo drive and motor, Siemens full color HMI.

3. Equipped with load cell with high sensitive weighing system. Make sure the high filling accuracy.

4. Two speed filling, quick filling and slow filling. Slow fills when weight approaches and just stops when it reachs.

5. Working process: Manual put on bag → Pneumatic hold bag → Bag lift up → Fast fill → Bag descends → Weight approaches → Slow fill → Weight reaches → Stop fill → Bag release → Manual take out bag.

6. Filling nozzle dives deep into bag bottom. Bag slowly descends as filling, so weight is less affect by inertia and less dusty.

7. Servo motor drives up-down platform, machine with lift function to avoid the dust fly.

Parameters

|

Model |

TP-PF-B11 |

TP-PF-B12 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

Quick disconnecting hopper 75L |

Quick disconnecting hopper 100L |

|

Packing Weight |

1kg-10kg |

1kg – 50kg |

|

Dosing mode |

With online weighing; Fast and slow filling |

With online weighing; Fast and slow filling |

|

Packing Accuracy |

1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

|

Filling Speed |

2– 25 times per min |

2– 25 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

2.5kw |

3.2 KW |

|

Total Weight |

400kg |

500kg |

|

Overall Dimensions |

1030×950×2700mm |

1130×950×2800mm |

Powder pouch filling machine

The powder filler can work together with packing machine to form powder sachet filling machine

Configuration list

|

No. |

Name |

Pro. |

Brand |

|

1 |

PLC |

Taiwan |

DELTA |

|

2 |

Touch Screen |

Taiwan |

DELTA |

|

3 |

Servo motor |

Taiwan |

DELTA |

|

4 |

Servo driver |

Taiwan |

DELTA |

|

5 |

Switching powder supply |

|

Schneider |

|

6 |

Emergency switch |

|

Schneider |

|

7 |

Contactor |

|

Schneider |

|

8 |

Relay |

|

omron |

|

9 |

Proximity switch |

Korea |

Autonics |

|

10 |

Level sensor |

Korea |

Autonics |

Accessories

|

No. |

Name |

Quantity |

Remark |

|

1 |

Fuse |

10pcs |

|

|

2 |

Jiggle switch |

1pcs |

|

|

3 |

1000g Poise |

1pcs |

|

|

4 |

Socket |

1pcs |

|

|

5 |

Pedal |

1pcs |

|

|

6 |

Connector plug |

3pcs |

Tool box

|

No. |

Name |

Quntity |

Remark |

|

1 |

Spanner |

2pcs |

|

|

2 |

Spanner |

1set |

|

|

3 |

Slotted screwdriver |

2pcs |

|

|

4 |

Phillips screwdriver |

2pcs |

|

|

5 |

User manual |

1pcs |

|

|

6 |

Packing list |

1pcs |

Detailed photos

1. Hopper

Level split hopper

It is very easy to open hopper and and do cleaning.

Disconnect hopper

it is not easy to take hopper apart do cleaning.

2. The way to fix auger screw

Screw type

it will make material stock,

and easy for cleaning.

Hang type

It will not make material stock, and become rust, not asy for cleaning.

3. Air outlet

Stainless steel type

It is easy for cleaning and beautiful.

Cloth type

It has to change termly for cleaning.

4. Level senor (Autonics)

5. Hand wheel

It gives signal to loader when material lever is low,

it does feed automatically.

It is suitable for filling into bottles/bags with different height.

6. Leakproof acentric device

It is suitable for filling products with very good fluidity, such as, salt, white sugar etc.

7. Auger screw and tube

In order to make sure filling accuracy, one size screw is suitable for one weight range, for example, dia. 38mm screw is suitable for filling 100g-250g.

FAQ

1. Are you a powder filling machine manufacturers?

Shanghai Tops Group Co., Ltd. is professional powder filling machine manufacturer in China, who has been in packing machine industry for over 15 years. We have sold our machines to more than 60 countries all over the world.

Shanghai Tops Group Co., Ltd. has got patents of powder filling machine.

We have abilities of designing, manufacturing as well customizing powder filling line.

2. Does your powder filling machine have CE certificate?

Yes, we have small powder filling machine CE certificate. And not only spice filling machine, all our machines have CE certificate.

3. What products can powder filling machine handle?

Particle filling machine can fill all kinds of powder or small granule products, such as, like pressed powder, face powder, pigment, eye shadow powder, cheek powder, glitter powder, highlighting powder, baby powder, talcum powder, iron powder, soda ash, calcium carbonate powder, plastic particle, polyethylene etc.

It is widely applied in industry of food, pharmaceutical, chemical and so on.

4. What’s the powder filling machine price?

The low cost powder filling machine price is based on product, filling weight, capacity, option, customization. Please advise your detailed packing requirements,

5. Where to find a fine powder filling machine for sale near me?

We have agents in Europe(Spain), USA. Welcome to check machine quality if possible for you. For other countries, we can provide customers reference if you need.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Best High Quality Powder Capsule Filling Machine Pricelist – Powder Filling Machine – Shanghai Tops, The product will supply to all over the world, such as: Armenia, Mexico, Argentina, Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!

-

OEM/ODM China Powder Machine Mixer - Double Ri...

-

China Wholesale Milk Powder Filling Machine Quo...

-

Factory Outlets Chemical Mixer Machine Price -...

-

Best High Quality Powder Filling Equipment Pric...

-

China Wholesale Full Automatic Essence Auger Fi...

-

Best High Quality Ribbon Blending Machine Quote...