Best High Quality Ribbon Blender Manufacturers Quotes – Ribbon Blender – Shanghai Tops Detail:

Video

General introduction

Ribbon blender for dry powder mixing

Ribbon blender for powder with liquid spray

Ribbon blender for granule mixing

Can ribbon blender mixer handle my product?

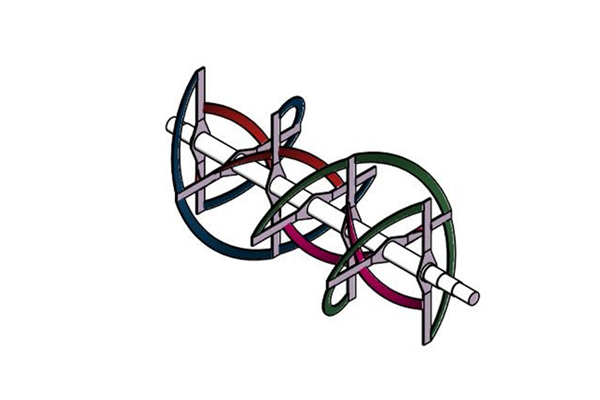

Working principle

The outer ribbon brings material from sides to the center.

The inner ribbon pushes material from the center to sides.

How does ribbon blender mixer work?

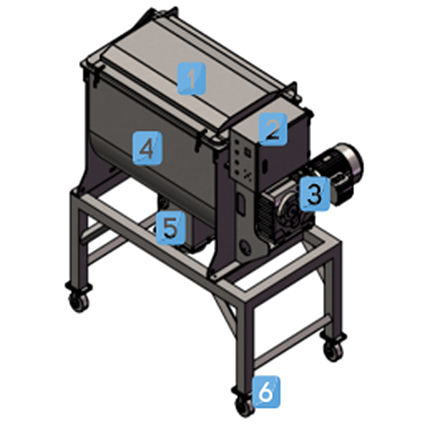

Ribbon Blender Design

Consist of

1: Blender Cover; 2:Electric Cabinet & Control Panel

3: Motor & Reducer; 4: Blender Tank

5: Pneumatic Valve; 6: Holder and Mobile Caster

Main features

■ Full welding at all connection parts.

■ All 304 stainless steel, and full mirror polished inside tank.

■ Special ribbon design makes no dead angle when mixing.

■ Patent Technology on double security shaft sealing.

■ Slightly concave flap controlled by pneumatic to achieve no leakage at discharge valve.

■ Round corner with silicone ring lid design.

■ With safety interlock, safety grid and wheels.

■ Slow rising keeps hydraulic stay bar long life.

How to choose a ribbon blender mixer machine?

Detailed

1. All work-pieces are connected by full welding. No residual powder and easy-cleaning after mixing.

2. Round corner and silicone ring make ribbon blender cover easy to clean.

3. Complete 304 stainless steel ribbon blender. Full mirror polished inside the mixing tank including ribbon and shaft.

4. The slightly concave flap at bottom center of the tank, which ensures no material left and no dead angle when mixing.

5. Double security shaft sealing design with Germany brand Burgmann packing gland ensures zero leaking when testing with water, which has been applied for a patent.

6. Slow rising design keeps hydraulic stay bar long life.

7. Interlock, grid and wheels for safe and convenient using.

Specification

|

Model |

TDPM 100 |

TDPM 200 |

TDPM 300 |

TDPM 500 |

TDPM 1000 |

TDPM 1500 |

TDPM 2000 |

TDPM 3000 |

TDPM 5000 |

TDPM 10000 |

|

Capacity(L) |

100 |

200 |

300 |

500 |

1000 |

1500 |

2000 |

3000 |

5000 |

10000 |

|

Volume(L) |

140 |

280 |

420 |

710 |

1420 |

1800 |

2600 |

3800 |

7100 |

14000 |

|

Loading rate |

40%-70% |

|||||||||

|

Length(mm) |

1050 |

1370 |

1550 |

1773 |

2394 |

2715 |

3080 |

3744 |

4000 |

5515 |

|

Width(mm) |

700 |

834 |

970 |

1100 |

1320 |

1397 |

1625 |

1330 |

1500 |

1768 |

|

Height(mm) |

1440 |

1647 |

1655 |

1855 |

2187 |

2313 |

2453 |

2718 |

1750 |

2400 |

|

Weight(kg) |

180 |

250 |

350 |

500 |

700 |

1000 |

1300 |

1600 |

2100 |

2700 |

|

Total Power (KW) |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

18.5 |

22 |

45 |

75 |

Click here to get ribbon blender diagram

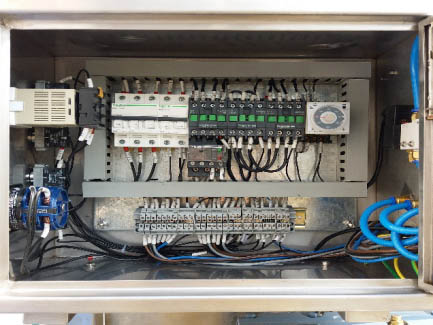

Accessories list

|

No. |

Name |

Brand |

|

1 |

Stainless steel |

China |

|

2 |

Circuit breaker |

Schneider |

|

3 |

Emergency switch |

Schneider |

|

4 |

Switch |

Schneider |

|

5 |

Contactor |

Schneider |

|

6 |

Assist contactor |

Schneider |

|

7 |

Heat relay |

Omron |

|

8 |

Relay |

Omron |

|

9 |

Timer relay |

Omron |

Configurations

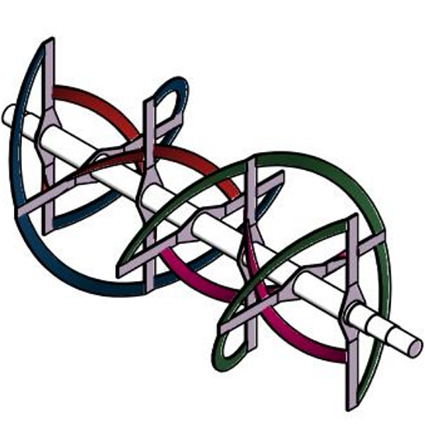

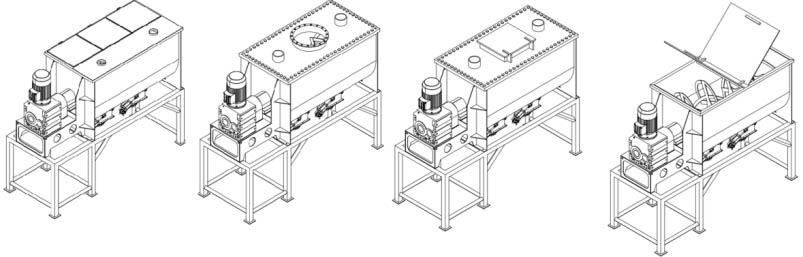

Optional Stirrer

Ribbon Blender

Paddle Blender

The appearance of ribbon and paddle blender is the same. The only difference is the stirrer between ribbon and paddle.

The ribbon is suitable for powder and material with closing density, and needs more force during mixing.

The paddle is suitable for granule like rice, nuts, beans and so on. It’s also used in powder mixing with big difference in density.

Moreover, we can customize stirrer combining paddle with ribbon, which is suitable for material between above two kinds characters.

Please let us know your material if you don’t know which stirrer is more suitable for you. You will get a best solution from us.

A: Flexible material selection

Material options SS304 and SS316L. And the two materials can be used in combination.

The surface treatment of stainless steel, including coated teflon, wire drawing, polishing and mirror polishing, can be used in different ribbon blender parts.

B: Various inlets

The barrel top cover of ribbon powder blender can be customized according to different cases.

C: Excellent discharge part

The ribbon blender discharge valve can be driven manually or pneumatically. Optional valves: cylinder valve, butterfly valve etc.

Normally the pneumatically has better sealing than manual one. And there is no dead angel at mixing tank and valve room.

But for some customers, the manual valve is more convenient to control discharge amount. And it is suitable for material with bag flowing.

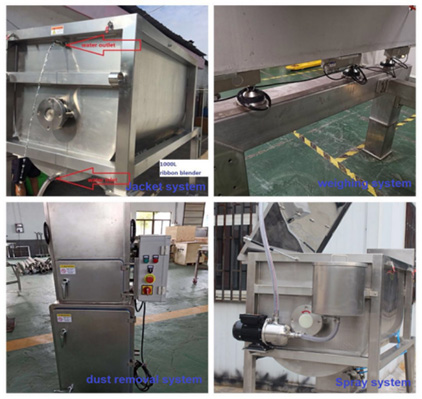

D: Selectable additional function

Double helical ribbon blender sometimes needs to be equipped additional functions because of customer requirements, like jacket system for heating and cooling, weighing system, dust removal system, spray system and so on.

Optional

A: Adjustable speed

Powder ribbon blender machine can be customized into speed adjustable by installing a frequency converter.

B: Loading system

In order to make the operation of industrial ribbon blender machine more convenient, stairs for small model mixer, working platform with steps for larger model mixer, or screw feeder for automatic loading are all available.

For the automatic loading part, there are three types of conveyor can be chosen: screw conveyor, bucket conveyor and vacuum conveyor. We will choose the most suitable type based on your product and situation. For example: Vacuum loading system is more suitable for high height difference loading, and is more flexible as well needs less space. Screw conveyor is not suitable for some material which will get sticky when temperature is little higher, but it is suitable for workshop who has limited height. Bucket conveyor is suitable for granule conveyor.

C: Production line

Double ribbon blender can works with screw conveyor, hopper and auger filler to form production lines.

Click here to get more details of powder mixing and filling line.

The production line save much energy and time for you comparing with manual operation.

The loading system will connect two machines to provide enough material timely.

It takes you less time and brings you higher efficiency.

Production and processing

Factory shows

FAQ

1. Are you a industrial ribbon blender manufacturer?

Shanghai Tops Group Co., Ltd is one of the leading ribbon blender manufacturers in China, who has been in packing machine industry for over ten years. We have sold our machines to more than 80 countries all over the world.

Our company has a number of invention patents of ribbon blender design as well other machines.

We have abilities of designing, manufacturing as well customizing a single machine or whole packing line.

2. Does your powder ribbon blender have CE certificate?

Not only the powder ribbon blender but also all our machines have CE certificate.

3. How long is the ribbon blender delivery time?

It takes 7-10 days to produce a standard model.

For customized machine, your machine can be done in 30-45 days.

Moreover, machine shipped by air is about 7-10 days.

Ribbon blender delivered by sea is about 10-60 days according to different distance.

4. What’s your company service and warranty?

Before you make the order, our sales will communicate all details with you until you get a satisfying solution from our technician. We can use your product or similar one in China market to test our machine, then feed you back the video to show the effect.

For the payment term, you can choose from following terms:

L/C, D/A, D/P, T/T, Western Union, Money Gram, Paypal

After making the order, you can appoint inspection body to check your powder ribbon blender in our factory.

For the shipping, we accept all term in contract like EXW, FOB, CIF, DDU and so on.

Warranty and after-service:

■ TWO YEAR warranty, ENGINE THREE YEARS warranty, life-long service

(Warranty service will be honored if the damage is not caused by human or improper operation)

■ Provide accessory parts in favorable price

■ Update configuration and program regularly

■ Respond to any question in 24 hours

■ Site service or online video service

5. Do you have the ability of design and propose solution?

Of course, we have professional design team and experienced engineer. For example, we designed a bread formula production line for Singapore BreadTalk.

6. Does your powder mixing blender machine have CE certificate?

Yes, we have powder mixing equipment CE certificate. And not only coffee powder mixing machine, all our machines have CE certificate.

Moreover, we have some technical patents of powder ribbon blender designs, such as shaft sealing design, as well auger filler and other machines appearance design, dust-proof design.

7. What products can ribbon blender mixer handle?

Ribbon blender mixer can handle all kinds of powder or granule mixing and is widely applied in food, pharmaceuticals, chemical and so on.

Food industry: all kinds of food powder or granule mix like flour, oat flour, protein powder, milk powder, coffee powder, spice, chilli powder, pepper powder, coffee bean, rice, grains, salt, sugar, pet food, paprika, microcrystalline cellulose powder, xylitol etc.

Pharmaceuticals industry: all kinds of medical powder or granule mix like aspirin powder, ibuprofen powder, cephalosporin powder, amoxicillin powder, penicillin powder, clindamycin powder, azithromycin powder, domperidone powder, amantadine powder, acetaminophen powder etc.

Chemical industry: all kinds of skin care and cosmetics powder or industry powder mix, like pressed powder, face powder, pigment, eye shadow powder, cheek powder, glitter powder, highlighting powder, baby powder, talcum powder, iron powder, soda ash, calcium carbonate powder, plastic particle, polyethylene etc.

Click here to check if your product can works on ribbon blender mixer.

8. How do industry ribbon blenders work?

Double layer ribbons which stand and turn in opposite angels to form a convection in different materials so that it can reach a high mixing efficiency.

Our special design ribbons can achieve no dead angle in mixing tank.

The effective mixing time is only 5-10 minutes, even less within 3 min.

9. How to select a double ribbon blender?

■ Select between ribbon and paddle blender

To select a double ribbon blender, the first thing is to confirm if the ribbon blender is suitable.

Double ribbon blender is suitable for mixing different powder or granule with similar densities and which is not easy to break. It is not suitable for material which will melt or get sticky in higher temperature.

If your product is the mix consist of materials with very different densities, or it is easy to break, and which will melt or get sticky when temperature is higher, we recommend you to select the paddle blender.

Because the working principles are different. Ribbon blender moves materials in opposite directions to achieve good mixing efficiency. But paddle blender brings materials from tank bottom to top, so that it can keep materials complete and won’t make temperature go up during mixing. It won’t make material with larger density staying at tank bottom.

■ Choose a suitable model

Once confirm to use the ribbon blender, it comes into making decision on volume model. Ribbon blenders from all suppliers have the effective mixing volume. Normally it is about 70%. However, some suppliers name their models as total mixing volume, while some like us name our ribbon blender models as effective mixing volume.

But most manufacturers arrange their output as weight not volume. You need to calculate the suitable volume according to your product density and batch weight.

For example, manufacturer TP produces 500kg flour each batch, whose density is 0.5kg/L. The output will be 1000L each batch. What TP needs is a 1000L capacity ribbon blender. And TDPM 1000 model is suitable.

Please pay attention to the model of other suppliers. Make sure 1000L is their capacity not total volume.

■ Ribbon blender quality

The last but the most important thing is to choose a ribbon blender with high quality. Some details as following are for reference where problems are most likely to occur on a ribbon blender.

Shaft sealing: test with water can show the shaft sealing effect. Powder leakage from shaft sealing always troubles users.

Discharge sealing: test with water also shows the discharge sealing effect. Many users have met leakage from discharge.

Full-welding: Full welding is one of the most important part for food and pharmaceutical machines. Powder is easy to hide in gap, which may pollute fresh powder if residual powder goes bad. But full-welding and polish can make no gap between hardware connection, which can show machine quality and usage experience.

Easy-cleaning design: A easy-cleaning ribbon blender will save much time and energy for you which is equal to cost.

10.What’s the ribbon blender price?

The ribbon blender price is based on capacity, option, customization. Please contact us to get your suitable ribbon blender solution and offer.

11.Where to find a ribbon blender for sale near me?

We have agents in several countries, where you can check and try our ribbon blender, who can help you one shipping and customs clearance as well after-service. Discount activities are held from time to time of one year. Contact us to get the latest price of ribbon blender please.

Product detail pictures:

Related Product Guide:

We will make just about every exertion for being excellent and perfect, and speed up our actions for standing during the rank of worldwide top-grade and high-tech enterprises for Best High Quality Ribbon Blender Manufacturers Quotes – Ribbon Blender – Shanghai Tops, The product will supply to all over the world, such as: Mauritania, Georgia, Argentina, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!

-

China Wholesale Dry Powder Filling Machine Fact...

-

Wholesale Dealers of Dry Powder Mixing Machine ...

-

Best quality Commercial Powder Mixer - Double ...

-

China Wholesale Bleach Powder Filling Auger Fil...

-

China Wholesale Powder Blender For Sale Supplie...

-

Best High Quality Large Industrial Blender Fact...