Best High Quality Semi Automatic Auger Filler Factory – Powder Auger Filler – Shanghai Tops Detail:

Video

Tops-packing auger filler

Shanghai Tops-group is a auger filler packing machine manufacturer. We have good production capacity as well advanced technology of auger powder filler. We have servo auger filler appearance patent.

On top of that, our average production time is only 7 days on standard design.

Moreover, we have ability to customize the auger filler according to your requirement. We can produce the auger filler based on your design drawing and with your logo or company information on machine label. We can also supply auger filler parts. If you have object configuration, we can also use the specific brand.

Key technology of servo auger filler

■ Servo motor: We use Taiwan brand Delta servo motor to control the auger, so as to reach high accuracy of filling weight. The brand can be appointed.

A servomotor is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity and acceleration. It consists of a suitable motor coupled to a sensor for position feedback. It also requires a relatively sophisticated controller, often a dedicated module designed specifically for use with servomotors.

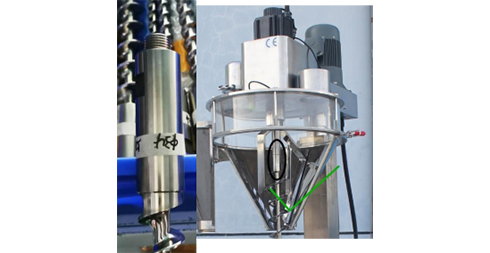

■ Central components: The central components of auger is the most important part for auger filler.

We do good job in central components, processing accuracy and assembly. Processing accuracy and assembly are invisible to the naked eye and cannot be compared intuitively, but it will show up during using.

■ High concentricity: The accuracy won’t be high if there is no high concentricity on auger and shaft.

We use world famous brand shaft between the auger and servo motor.

■ Servo motor: We use Taiwan brand Delta servo motor to control the auger, so as to reach high accuracy of filling weight. The brand can be appointed.

A servomotor is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity and acceleration. It consists of a suitable motor coupled to a sensor for position feedback. It also requires a relatively sophisticated controller, often a dedicated module designed specifically for use with servomotors.

■ Central components: The central components of auger is the most important part for auger filler.

We do good job in central components, processing accuracy and assembly. Processing accuracy and assembly are invisible to the naked eye and cannot be compared intuitively, but it will show up during using.

■ Precision machining: We use milling machine to mill small size auger, which makes the auger have same distances and very accurate shape.

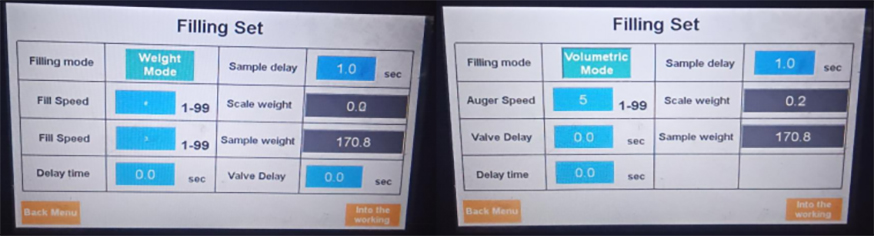

■ Two filling modes: Can be switched between weight mode and volume mode.

Volume mode:

The powder volume brought down by screw turning one round is fixed. The controller will calculate how many turns the screw has to turn to reach the target filling weight.

Weight mode:

There is a load cell under filling plate to measure filling weight timely.

First filling is fast and mass filling to get 80% of target filling weight.

Second filling is slow and accurate to supplement the rest 20% according to timely filling weight.

auger filler machine price

Click here to get the auger filler price or auger filler for sale.

Auger filler machine type

Semi-automatic Auger Filler

The semi-automatic auger filler is suitable for low speed filling. Because it needs operator to place bottles on plate under the filler and move away bottles after filling manually. It can handle both bottle and pouch package. The hopper has option of full stainless steel. And the sensor can be chosen between tuning fork sensor and photoelectric sensor. You can get small auger filler and standard model as well high level model auger filler for powder from us.

|

Model |

TP-PF-A10 |

TP-PF-A11 |

TP-PF-A14 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

11L |

25L |

50L |

|

Packing Weight |

1-50g |

1 – 500g |

10 – 5000g |

|

Weight dosing |

By auger |

By auger |

By auger |

|

Weight Feedback |

By off-line scale (in picture) |

By off-line scale (in picture) |

By off-line scale (in picture) |

|

Packing Accuracy |

≤ 100g, ≤±2% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Filling Speed |

40 – 120 times per min |

40 – 120 times per min |

40 – 120 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

0.84 KW |

0.93 KW |

1.4 KW |

|

Total Weight |

90kg |

160kg |

260kg |

|

Overall Dimensions |

590×560×1070mm |

800×790×1900mm |

1140×970×2200mm |

Semi-automatic Auger Filler with Pouch Clamp

This semi-automatic auger filler with pouch clamp is suitable for pouch filling. The pouch clamp will hold the bag automatically after stamping the pedal plate. It will loose bag automatically after filling. The TP-PF-B12 has a plate to raise and fall bag during filling to reduce dust and weight error because it is the big model. When powder dispense from end of filler to bottom of bag, the gravity will lead error because there is load cell detect real-time weight. The plate raises bag so that filling tube will stick into bag. And the plate falls slowly during filling.

|

Model |

TP-PF-A11S |

TP-PF-A14S |

TP-PF-B12 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

25L |

50L |

100L |

|

Packing Weight |

1 – 500g |

10 – 5000g |

1kg – 50kg |

|

Weight dosing |

By load cell |

By load cell |

By load cell |

|

Weight Feedback |

Online weight feedback |

Online weight feedback |

Online weight feedback |

|

Packing Accuracy |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

|

Filling Speed |

40 – 120 times per min |

40 – 120 times per min |

2– 25 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

0.93 KW |

1.4 KW |

3.2 KW |

|

Total Weight |

160kg |

260kg |

500kg |

|

Overall Dimensions |

800×790×1900mm |

1140×970×2200mm |

1130×950×2800mm |

Line-type Automatic Auger Filler for Bottles

The line-type automatic auger filler applies in powder bottle filling. It can be connected with powder feeder, powder mixer, capping machine and labeling machine to form a automatic packing line. The conveyor brings bottles in and the bottle stopper holds back bottles so as bottle holder can raise bottle under the filler. The conveyor moves bottles forward after filling automatically. It can handle different sizes bottle on one machine and is suitable for user who has more than one dimensions packages.

The halt stainless steel and fully stainless steel hopper is optional. There are two types sensor available. And it can be customized to add online weighing function to achieve very high precision.

|

Model |

TP-PF-A21 |

TP-PF-A22 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

25L |

50L |

|

Packing Weight |

1 – 500g |

10 – 5000g |

|

Weight dosing |

By auger |

By auger |

|

Weight Feedback |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Packing Accuracy |

40 – 120 times per min |

40 – 120 times per min |

|

Filling Speed |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

1.2 KW |

1.6 KW |

|

Total Weight |

160kg |

300kg |

|

Overall Dimensions |

1500×760×1850mm |

2000×970×2300mm |

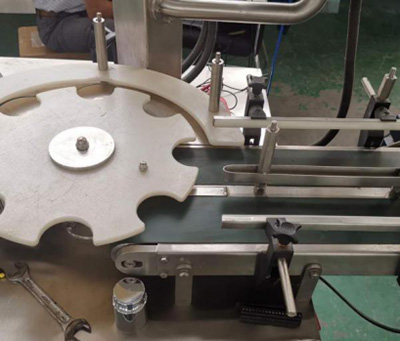

Rotary Automatic Auger Filler

Rotary auger filler is used to fill powder into bottles with high speed. This kind of auger filler is suitable for customer who has only one or two diameter sizes bottles because the bottle wheel can handle only one diameter. However, the accuracy and speed is better than line type auger filler. On top of that, rotary type has online weighing and rejection function. The filler will fill powder according to real time filling weight, and rejection function will detect and get rid of unqualified weight.

The machine cover is optional.

|

Model |

TP-PF-A31 |

TP-PF-A32 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

35L |

50L |

|

Packing Weight |

1-500g |

10 – 5000g |

|

Weight dosing |

By auger |

By auger |

|

Container size |

Φ20~100mm ,H15~150mm |

Φ30~160mm ,H50~260mm |

|

Packing Accuracy |

≤ 100g, ≤±2% 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% ≥500g,≤±0.5% |

|

Filling Speed |

20 – 50 times per min |

20 – 40 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

1.8 KW |

2.3 KW |

|

Total Weight |

250kg |

350kg |

|

Overall Dimensions |

1400*830*2080mm |

1840×1070×2420mm |

Double head auger filler for powder

Double head auger filler is suitable for high speed filling. The maximum speed and reach 100bpm. The check weighing and reject system prevent expensive product wasting because of high accuracy weight control. It is widely used in milk powder production line.

|

Dosing mode |

Double lines dual filler filling with online weighing |

|

Filling Weight |

100 – 2000g |

|

Container Size |

Φ60-135mm; H 60-260mm |

|

Filling Accuracy |

100-500g, ≤±1g; ≥500g,≤±2g |

|

Filling Speed |

Above 100 cans/min(#502),Above 120 cans/min(#300 ~ #401) |

|

Power Supply |

3P AC208-415V 50/60Hz |

|

Total Power |

5.1 kw |

|

Total Weight |

650kg |

|

Air Supply |

6kg/cm 0.3cbm/min |

|

Overall Dimension |

2920x1400x2330mm |

|

Hopper Volume |

85L(Main) 45L (Assist) |

Powder Packing system

When the auger filler works with packing machine, it forms a powder packing machine. It can be connected with roll film sachet making filling and sealing machine, or the mini doypack packing machine and rotary pouch packing machine or preformed pouch.

Auger filler features

■ Turning auger to ensure high filling accuracy.

■ PLC control with touchscreen, which is easy to operate.

■ The servo motor drives the auger to ensure stable performance.

■ Quickly disconnect hopper is easy cleaning without tools.

■ Whole machine is stainless steel 304 material.

■ The online weighing function and the proportion tracking of the material overcome the difficulty of the filling weight change caused by the change of material density.

■ Keep 20 sets of recipes in the program for easy later use.

■ Replacing auger to pack different products with different weights, from fine powder to particles.

■ With the function of rejecting substandard weight.

■ Multilingual interface

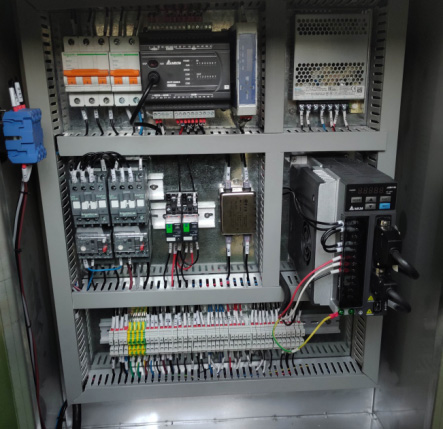

Confihuration List . A,

|

No. |

Name |

Pro. |

Brand |

|

1 |

PLC |

Taiwan |

DELTA |

|

2 |

Touch Screen |

Taiwan |

DELTA |

|

3 |

Servo motor |

Taiwan |

DELTA |

|

4 |

Servo driver |

Taiwan |

DELTA |

|

5 |

Switching powder |

|

Schneider |

|

6 |

Emergency switch |

|

Schneider |

|

7 |

Contactor |

|

Schneider |

|

8 |

Relay |

|

omron |

|

9 |

Proximity switch |

Korea |

Autonics |

|

10 |

Level sensor |

Korea |

Autonics |

B: Accessories

|

No. |

Name |

Quantity |

Remark |

|

1 |

Fuse |

10pcs |

|

|

2 |

Jiggle switch |

1pcs |

|

|

3 |

1000g Poise |

1pcs |

|

|

4 |

Socket |

1pcs |

|

|

5 |

Pedal |

1pcs |

|

|

6 |

Connector plug |

3pcs |

C: Tool box

|

No. |

Name |

Quntity |

Remark |

|

1 |

Spanner |

2pcs |

|

|

2 |

Spanner |

1set |

|

|

3 |

Slotted screwdriver |

2pcs |

|

|

4 |

Phillips screwdriver |

2pcs |

|

|

5 |

User manual |

1pcs |

|

|

6 |

Packing list |

1pcs |

Auger filler details

1. Optional hopper

Half open hopper

This level split hopper is

easy to open and clean.

Hanging hopper

The combined hopper is suitable for very fine powder because the there is no gap at lower part of hopper

2. Filling mode

Can be switched between weight mode and volume mode.

Volume mode

The powder volume brought down by screw turning one round is fixed. The controller will calculate how many turns the screw has to turn to reach the target filling weight.

Weight mode

There is a load cell under filling plate to measure filling weight timely.

First filling is fast and mass filling to get 80% of target filling weight.

Second filling is slow and accurate to supplement the rest 20% according to timely filling weight.

Weight mode has higher accuracy but lower speed.

Auger fillers from other suppliers’ only one mode: volume mode

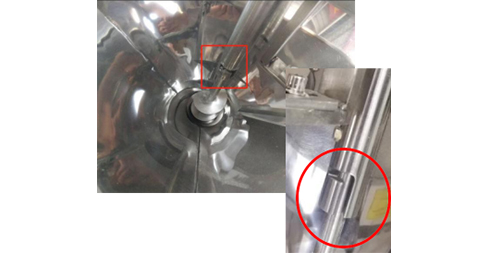

3. Auger fixing way

Shanghai Tops-group: Screw type

There is no gap for

powder to hide inside,

and easy to clean

Other suppliers: Hang type

There will be powder hiding inside the hang connection part, which is difficult to clean, and will turn bad even pollute fresh powder.

4. Hand wheel

Shanghai Tops-group

Other supplier

It is suitable for filling in bottles/bags with different height. Turn hand wheel to rise and down filler. And our holder is thicker and more strong than others.

5. Processing

Shanghai Tops-group

full welding, including hopper edge.

Easy to clean

6. Motor base

7. Air outlet

The whole machine is made of SS304 including the base and holder of motor, which is stronger and high level.

The holder of motor is not SS304.

8. Two output accesses

Bottles with qualified filling

weight goes through one access

Bottles with unqualified filling

weight will be rejected automatically

to the other access on belt.

9. Different sizes metering auger and filling nozzles

The auger filler principle is that volume of powder brought down by auger turning one circle is fixed. So different sizes of auger can be used in different filling weight range to reach higher accuracy and save more time.

There are corresponding size auger tube for each size auger.

for example, dia. 38mm screw is suitable for filling 100g-250

Followings are auger sizes and related filling weight ranges

Cup Size and Filling Range

|

Order |

Cup |

Inner Diameter |

Outer Diameter |

Filling Range |

|

1 |

8# |

8 |

12 |

|

|

2 |

13# |

13 |

17 |

|

|

3 |

19# |

19 |

23 |

5-20g |

|

4 |

24# |

24 |

28 |

10-40g |

|

5 |

28# |

28 |

32 |

25-70g |

|

6 |

34# |

34 |

38 |

50-120g |

|

7 |

38# |

38 |

42 |

100-250g |

|

8 |

41# |

41 |

45 |

230-350g |

|

9 |

47# |

47 |

51 |

330-550g |

|

10 |

53# |

53 |

57 |

500-800g |

|

11 |

59# |

59 |

65 |

700-1100g |

|

12 |

64# |

64 |

70 |

1000-1500g |

|

13 |

70# |

70 |

76 |

1500-2500g |

|

14 |

77# |

77 |

83 |

2500-3500g |

|

15 |

83# |

83 |

89 |

3500-5000g |

If you are not sure your suitable auger size, please contact us and we will choose the best suitable size auger for you.

Auger filler factory show

Auger filler processing

Computer Aided Design

milling

drilling

Turning

bending

welding

Polishing

buffing

electric control

How to maintain the auger filler?

■ Add a little Grease on stir motor chain once in three or four months.

■ The sealing strip on both sides of hopper become aging nearly one year later. Replace them if needed.

■ Clean hopper in time.

Product detail pictures:

Related Product Guide:

We offer great strength in quality and development,merchandising,sales and marketing and operation for Best High Quality Semi Automatic Auger Filler Factory – Powder Auger Filler – Shanghai Tops, The product will supply to all over the world, such as: Algeria, Libya, Congo, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beauty and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!

-

Rapid Delivery for Dry Spice Mixer - Double sh...

-

OEM China Horizontal Double Ribbon Mixer - Dou...

-

Fixed Competitive Price Rice Mixer - Double sh...

-

China Wholesale Ribbon Blender Diagram Factorie...

-

China Wholesale Auger Filler Packing Machine Fa...

-

China Wholesale Automatic Powder Capsule Fillin...