Description:

Usage:

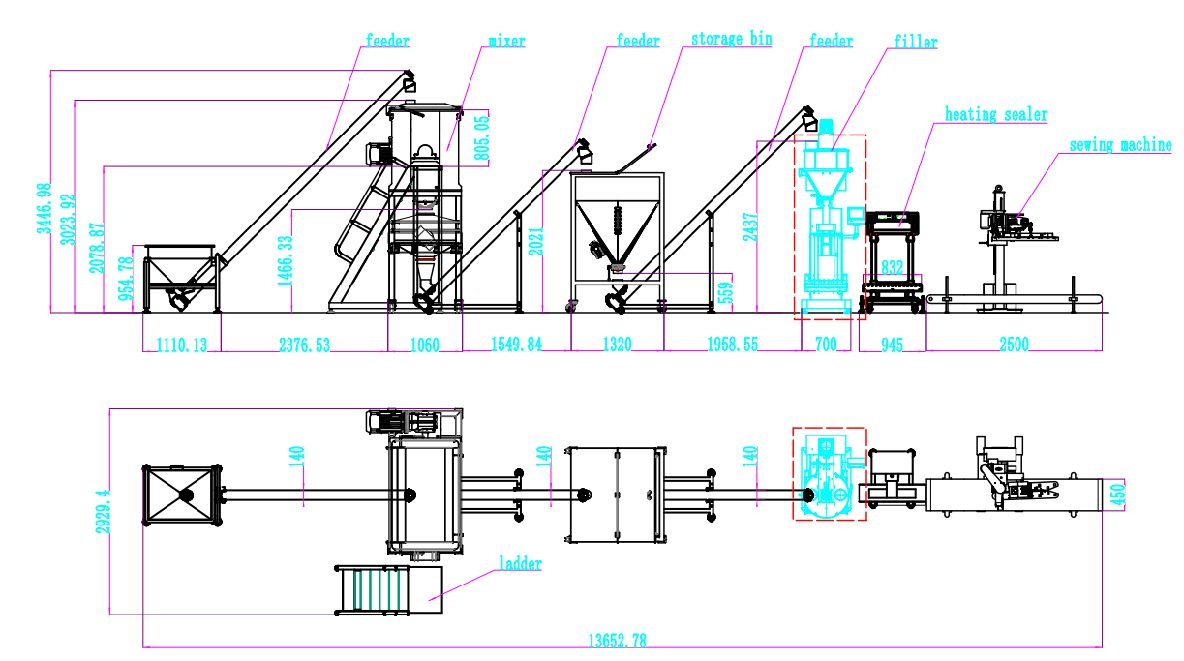

Large bag filling and packing line, mainly suitable for powder, pellet material and need to use large bag packaging.

The production line is mainly composed of feeding machine, mixing machine, vibrating screen, hopper, filling machine and sewing machine.

Of course, the equipment can be added or subtracted according to different needs.

Production line details:

☆Screw Feeder

General Introduction:

The screw feeder can convey powder and granule material from one machine to another.

It's efficient and convenient. It can work in cooperation with the packing machines to form a production line.

So it is widely used in packaging line, especially semi-auto and automatic packaging line. It is mainly used in conveying powder materials, such as the milk powder, protein powder, rice powder, milk tea powder, solid beverage, coffee powder, sugar, glucose powder, food additives, feed, pharmaceutical raw materials, pesticide, dye, flavour, fragrances and so on.

Main Features:

Hopper is vibratory which makes material to flow down easily.

Simple structure in linear type ,easy in installation and maintenance.

The whole machine is made of SS304 to reach the food grade request.

Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

High pressure double crank to control the die opening and closing.

Running in a high automation and intelligentialize,no pollution

Apply a linker to connect with the air conveyor ,which can directly inline with filling machine.

Specification:

| Main Specification | HZ-2A2 | HZ-2A3 | HZ-2A5 | HZ-2A7 | HZ-2A8 | THZ-2A12 |

| Charging Capacity | 2m³/h | 3m³/h | 5m³/h | 7m³/h | 8m³/h | 12m³/h |

| Diameter of pipe | Φ102 | Φ114 | Φ141 | Φ159 | Φ168 | Φ219 |

| Hopper Volume | 100L | 200L | 200L | 200L | 200L | 200L |

| Power Supply | 3P AC208-415V 50/60HZ | |||||

| Total Power | 610W | 810W | 1560W | 2260W | 3060W | 4060W |

| Total Weight | 100kg | 130Kg | 170Kg | 200Kg | 220Kg | 270Kg |

| Overall Dimensions of Hopper | 720×620×800mm | 1023×820×900mm | ||||

| Charging Height | Standard 1.85M,1-5M could be designed and manufactured | |||||

| Charging angle | Standard 45 degree ,30-60 degree are also available | |||||

☆Double Ribbon Mixer

General Introduction:

Horizontal ribbon mixer is widely used in chemical, pharmaceuticals, food, and construction line.It can be used to mix powder with powder, powder with liquid, and powder with granule.Under the driven of motor, the double ribbon agitator let the material to get a high effective convective mixing in short time.

Main Features:

Under the bottom of the tank, there has a flap dome valve (pneumatic control or manual control) of the center. The valve is arc design that assure no material accumulated and without any dead angle when mixing. Reliable regula- seal prohibit the leakage between the frequent close and open.

The double ribbon of the mixer can make the material mixed with more high speed and uniformity in short time

Whole machine stainless steel 304 material and full mirror polished inside of mixing tank, as well as ribbon and shaft. l

With safety switch, safety grid and wheels for safe and convenient using.

Specification:

|

Model |

TDPM 100 |

TDPM 200 |

TDPM 300 |

TDPM 500 |

TDPM 1000 |

TDPM 1500 |

TDPM 2000 |

TDPM 3000 |

TDPM 5000 |

TDPM 10000 |

|

Capacity(L) |

100 |

200 |

300 |

500 |

1000 |

1500 |

2000 |

3000 |

5000 |

10000 |

|

Volume(L) |

140 |

280 |

420 |

710 |

1420 |

1800 |

2600 |

3800 |

7100 |

14000 |

|

Loading rate |

40%-70% |

|||||||||

|

Length(mm) |

1050 |

1370 |

1550 |

1773 |

2394 |

2715 |

3080 |

3744 |

4000 |

5515 |

|

Width(mm) |

700 |

834 |

970 |

1100 |

1320 |

1397 |

1625 |

1330 |

1500 |

1768 |

|

Height(mm) |

1440 |

1647 |

1655 |

1855 |

2187 |

2313 |

2453 |

2718 |

1750 |

2400 |

|

Weight(kg) |

180 |

250 |

350 |

500 |

700 |

1000 |

1300 |

1600 |

2100 |

2700 |

|

Total Power |

3KW |

4KW |

5.5KW |

7.5KW |

11KW |

15KW |

18.5KW |

22KW |

45KW |

75KW |

☆Auger Feeding Machine

General Introduction:

ZS series vibrated filter is one of precised powder griddle,Low noise, high efficiency, need only 2~3 minutes to rapidly replace the griddle, all closed structure. Used to filter particles and powder .

Main Features:

High efficiency, refined design, duration,any powders and mucilage are suitable for using.

Easy to replace the net, simple operation and convenience washing.

Never jam the hole mesh

Discharge the impurity and coarse materials automobile and operates continuously.

Unique net flame design, long duration of net, only 3-5 to replace the network.

Small volume, move easily.

The highest layers of the griddle are about 5 layers. 3 lagers are suggested.

Specification:

|

Model |

TP-KSZP-400 |

TP-KSZP-600 |

TP-KSZP-800 |

TP-KSZP-1000 |

TP-KSZP-1200 |

TP-KSZP-1500 |

TP-KSZP-1800 |

TP-KSZP-2000 |

|

Diameter(mm) |

Φ400 |

Φ600 |

Φ800 |

Φ1000 |

Φ1200 |

Φ1500 |

Φ1800 |

Φ2000 |

|

Effective area(m2) |

0.13 |

0.24 |

0.45 |

0.67 |

1.0 |

1.6 |

2.43 |

3.01 |

|

Mesh |

2-400 |

|||||||

|

Material size(mm) |

<Φ10 |

<Φ10 |

<Φ15 |

<Φ20 |

<Φ20 |

<Φ20 |

<Φ30 |

<Φ30 |

|

Frequency(rpm) |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

|

Power(Kw) |

0.2 |

0.55 |

0.75 |

1.1 |

1.5 |

2.2 |

3 |

3 |

|

Height to 1st layer |

605 |

605 |

730 |

810 |

970 |

1000 |

1530 |

1725 |

|

Height to 2nd layer |

705 |

705 |

860 |

940 |

1110 |

1150 |

1710 |

1905 |

|

Height to 3rd layer |

805 |

805 |

990 |

1070 |

1250 |

1300 |

1890 |

2085 |

☆Automatic Cans Sealing machine

General Introduction:

Used for material storage.

Accessories and options: Stirrer,Safety griddle net , Level sensor, and so on.

Main Features:

All made of 304 stainless steel except for motor.

All specifications storage tank: Both round and rectangular style.

Hopper volume: 0.25-3cbm(Other volume could be designed Andmanufactured.)

☆Big Bag Auger Filling Machine

General Introduction:

This model is designed mainly for the fine powder which easily to spout dust and high-accuracy packing requirement. Based on the feedback sign given by below weight sensor, this machine do measuring, two-filling , and up-down work ,etc. It is specially suitable for filling additives, carbon powder, dry powder of fire extinguisher, and other fine powder which needs high packing accuracy.

griddle net , Level sensor, and so on.

Main Features:

Lathing auger screw to guarantee the precise filling accuracy

PLC control and touch screen display

Servo motor drives screw to guarantee stable performance

Quick disconnecting hopper could be washed easily without tools

Can be setting to semi-auto filling by pedal switch or auto filling

Weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials’ density change.

Replacing the auger parts, different products ranging from fine powder to granule and different weight can be packed

Weight sensor is below the tray, to do fast filling and slow filling based on the pre-set weight, to guarantee the high packaging accuracy.

Process: put bag/can(container) on the machine → container raise → fast filling,container declines → weight reaches the pre-set number → slow filling → weight reaches the goal number → take the container away manually

Specification:

|

Model |

TP-PF-B11 |

TP-PF-B12 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

75L |

100L |

|

Packing Weight |

1kg-10kg |

1kg – 50kg |

|

Weight dosing |

By load cell |

By load cell |

|

Weight Feedback |

Online weight feedback |

Online weight feedback |

|

Packing Accuracy |

1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

|

Filling Speed |

2– 25 times per min |

2– 25 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

|

3.2 KW |

|

Total Weight |

400kg |

500kg |

|

Overall Dimensions |

|

1130×950×2800mm |

☆Bag Sewing Machine

General Introduction:

This is a kind of device that can hem the bag mouth of woven bag, and stitched by sewing machine Using this device,we can remarkably improve packaging fastness, effectively avoid bales off and leaking packages.

High speed transportation seam package for Profession pellet and powder material and so on, like rice, bread flour, feed, chemical fertilizer, industrial chemicals, sugar.

Main Features:

It adopts imported reducer and motor.

It has characteristics of advanced structure,

big range of speed regulation.

Superior hemming property.

Easy operation and convenient maintenance.

Production line show:

Installation and Maintenance

About us:

Shanghai Tops Group Co., Ltd. Which is a professional enterprise of designing, manufacturing, selling powder pellet packaging machinery and taking over complete sets of engineering.

Since the company founded, it has successfully developed several series, dozens of varieties of packaging machinery and equipment,all the products meet the GMP requirements.We have sold our machines to more than 80 countries all over the world.Our company has a number of invention patents of ribbon blender design as well other machines.

With many years’ development, we have built our own technician team with innovative technicians and marketing elites, and we successfully develop many advanced products as well as help customer design series of package production lines.

We are struggling to be the“first leader”among the same range of filed of packaging machinery. On the way to success, we need your utmost support and cooperation. Let’s work hard altogether and make much greater success!

FAQ

1:Why we can choose you?

Reliable---we are the real company, we dedicate in win-win

Professional---we offer the filling machine exactly you want

Factory---we have factory, so have reasonable price

2:How about the price?Can you make it cheaper?

A:The price depends on the item your demand(model,quantity)Beat quotation after receving full description of the item you

3:How long is the machine delivery time?

Normally, our delivery time is 25 days after we receive the deposit.If the order is big, we need to extend thedelivery time.

4:How does your factory do regarding quality control?

Quality is priorityl Every worker keeps the QC from the very beginning to the very end, all material we usedare meet GB standard, skilful workers care every detail in handing each process,Quality control departmentspecially responsible for quality checking in each process.

5:What's your company service and warranty?

Before you make the order, our sales will communicate all details with you until you get a satisfying solution from our

technician. We can use your product or similar one in China market to test our machine, then feed you back the video to show the effect.

For the payment term, you can choose from following terms:

L/C, D/A, D/P, T/T, Western Union, Money Gram, Paypal

After making the order, you can appoint inspection body to check your powder ribbon blender in our factory.

For the shipping, we accept all term in contract like EXW, FOB, CIF, DDU and so on.

Warranty and after-service:

■ TWO YEAR warranty, ENGINE THREE YEARS warranty, life-long service

(Warranty service will be honored if the damage is not caused by human or improper operation)

■ Provide accessory parts in favorable price

■ Update configuration and program regularly

■ Respond to any question in 24 hours

■ Site service or online video service

6:Do you have the ability of design and propose solution?

Of course, we have professional design team and experienced engineer. For example, we designed a bread formula production line for Singapore Bread Talk.

7:Does your powder ribbon blender have CE certificate?

Not only the powder ribbon blender but also all our machines have CE certificate.

8:Are you a factory or agent?

We are an OEM, we always design and manufacture our products ourselves,so we could provide satisfactorytechnical and after-sales service.

You could pay a visit to our factory any time you like.