China Wholesale Semiauto Indgredient Auger Screw Filling Machine Factories – Auto liquid filling & capping machine – Shanghai Tops Detail:

Descriptive abstract

This automatic rotary filling capping machine is designed to filling E-liquid, cream and sauce products into bottles or jars, such as edible oil, shampoo, liquid detergent, tomato sauce and so on. It is widely used for filling bottles and jars of different volumes, shapes and materials. It can be customized according to the requirements of our customers. We can also add it with capping machine, labeling machine, even some other processing equipment to make it a complete.

Working principle

The machine adopt servo motor driven, containers will be sent to the position, then the filling heads will dive into the container, filling volume and filling time can be set in orderly. When it filled up to the standard, servo motor go up, container will be sent out, one working cycle is finished.

Characteristics

■ Advanced Human-machine interface. Filling volume can be set directly and all the data can be adjusted and saved.

■ Being driven by servo motors makes the filling accuracy higher.

■ Perfect homocentric cut stainless steel piston makes the machine with high precision and working life of the sealing rings last longer.

■ All material contacting part is made of SUS 304. It is corrosion resistance and completely in conformity with standard of food hygiene.

■ Anti-foam and leaking functions.

■ The piston is controlled by servo motor so that the filling accuracy of each filling nozzle will be more stable.

■ The filling speed of cylinder filling machine is fixed. But you can control the speed of each filling action if using the filling machine with servo motor.

■ You can save several group of parameters on our filling machine for different bottles.

Technical specification

|

Kind of bottle |

Various kinds of plastic/glass bottle |

|

Bottle size* |

Min. Ø 10mm Max. Ø80mm |

|

Kind of cap |

Alternative Screw on cap, alum. ROPP cap |

|

Cap size* |

Ø 20~ Ø60mm |

|

Filing nozzles |

1 head (can be customize 2-4 heads) |

|

Speed |

15-25bpm (e.g 15bpm@1000ml) |

|

Alternative Filling volume* |

200ml-1000ml |

|

Filling accuracy |

±1% |

|

Power* |

220V 50/60Hz 1.5kw |

|

Compress air require |

10L/min, 4~6bar |

|

Machine size mm |

Length 3000mm, width 1250mm, height 1900mm |

|

Machine weight: |

1250kgs |

Sample picture

Details

With touch screen control panel, the operator just need to enter the number to set parameter, makes it more convenient to control the machine, save time on testing machine.

Designed with pneumatic filling nozzle, it is suitable for filling thicker liquid like lotion, perfume, essential oil. Nozzle can be customize according to customer’s speed.

The cap feeding mechanism will arrange caps, feed caps automatically make the machine can work in order. The cap feeder will be customized according to your needs.

The chuck fix the bottle to rotate and tighten the bottle cap. This kinds of capping method makes it suitable for different kinds of bottle caps like spray bottles, water bottle, dropper bottles.

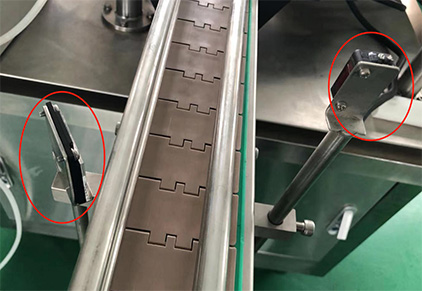

Equipped with high quality electric eye,these are designed for detecting bottles and control each mechanism of the machine to work or prepare the next process.Ensure the production quality.

Optional

1. Other cap feeding device

If your cap can not use vibrating plate for unscrambling and feeding, cap elevator is available.

2. Bottle unscrambling turning table

This bottle unscrambling turning table is a dynamic worktable with frequency control. Its procedure: put bottles onto round turntable, then turntable rotate to poke bottles onto conveying belt, capping is began when bottles are sent into capping machine.

If your bottle/jars diameter is large, you can choose large diameter unscrambling turning table, such as 1000mm diameter, 1200mm diameter, 1500mm diameter. If your bottle/jars diameter is small, you can choose small diameter unscrambling turning table, such as 600mm diameter, 800mm diameter.

3. Or Automatic unscrambling machine

This series automatic bottle unscrambling machine sorts round bottles automatically and places the containers on a conveyor at speeds up to 80 cpm. This unscrambling machine adopts electronic timing system. The operation is easy and stable. It is useful widely in the pharmacy, food & beverage, cosmetic & personal care industries.

4. Labeling machine

The automatic labeling machine designed for round bottles or other common cylindrical products. Such as cylindrical plastic bottles, glass bottles, metal bottles. It is mainly used for labeling of round bottles or round containers in food and beverage, medicine, and daily chemical industries.

■ Labeling self-adhesive sticker on top, flat or big radians surface of product.

■ Products Applicable: square or flat bottle, bottle cap, electrical components etc.

■ Labels Applicable: adhesive stickers in roll.

Our service

1. We will answer your enquiry within 12 hours.

2. Warranty time: 1 year(main part for you freely within 1 year, such as motor).

3. We will send the English instruction manual and operate video of the machine for you.

4. After-sales service: We will follow up our customers all the time after selling out the machine and also can send technician abroad to help you install and adjust the large machine if needed.

5. Accessories: We supply the spare parts with competitive price when you need it.

FAQ

1. Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you.

In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

2. How can we make sure about the machine quality after placking the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality.

And also you can arrange for quality checking by yourself or by your contacts in China.

3. We are afraid you won’t send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use Alibaba trade assurance service, guarantee your money, and guarantee your machine’s on-time delivery and machine quality.

4. Can you explain me the whole transaction process ?

1. Sign the Contact or Proforma invoice

2. Arrange 30% deposit to our factory

3. Factory arrange production

4. Testing & detecting the machine before shipping

5. Inspected by customer or third agency through online or site test.

6. Arrange the balance payment before shipment.

5. Will you provides the delivery service?

Yes. Please inform us of your final destination, we will check with our shipping department to quote the shipping cost for your reference before delivery. We have our own freight forwarding company, so the freight is also more advantageous. In the UK and the United States set up our own branches, and the UK and the United States customs direct cooperation, master the first-hand resources, eliminate the information difference at home and abroad, the whole process of goods progress can realize real-time tracking. Foreign companies have their own customs brokers and trailer companies to help the consignee to quickly clear customs and deliver goods, and make sure the goods arrive safely and on time. For the goods exported to Britain and the United States, consignors can consult us if they have any questions or don’t understand. We will have professional staff to give a full response.

6. How long does the auto filling &capping machine lead time?

For standard filling & capping machine, the lead time is 25 days after receiving your down payment. As to customized machine, the lead time is about 30-35 days upon receiving your deposit. Such as customize motor, customize additional function, etc.

7. What about your company service?

We Tops Group focus on service in order to provide a optimal solution to customers including before-sales service and after-sales service. We have stock machine in showroom for making test to help customer make final decision. And we also have agent in Europe, you can make a testing in our agent site. If you place order from our Europe agent, you also can get after-sale service in your local. We always care about your filling &capping machine running and after-sales service is always at your side to ensure everything runs perfectly with guaranteed quality and performance.

Regarding after-sales service, if you place order from Shanghai Tops Group, within one year’s warranty, if the liquid filling & capping machine have any problem, we will free send the parts for replacement, including express fee. After warranty, if you need any spare parts, we will give you the parts with cost price. In case of your capping machine fault happening, we will help you to deal with it in first time, to send picture/video for guidance, or live online video with our engineer for instruction.

8. Do you have the ability of design and propose solution?

Of course, we have professional design team and experienced engineer. For example, if your bottle/jar shape is special, you need send your bottle and cap samples to us, then we will design for you.

9. What shape bottle/jar can filling machine handle?

It is best suitable for Round and square, other irregular shapes of Glass, Plastic, PET, LDPE, HDPE Bottles, need confirm with our engineer. The bottles/jars hardness must can be clamped, or it can not screw tight.

Food industry: all kinds of food, spices bottle/jars, drink bottles.

Pharmaceuticals industry: all kinds of medical and health care products bottles/jars.

Chemical industry: all kinds of skin care and cosmetics bottles/jars.

10. How can i get the price?

We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Product detail pictures:

Related Product Guide:

Our staff through skilled training. Skilled skilled knowledge, potent sense of company, to satisfy the provider requirements of consumers for China Wholesale Semiauto Indgredient Auger Screw Filling Machine Factories – Auto liquid filling & capping machine – Shanghai Tops, The product will supply to all over the world, such as: Slovak Republic, UK, Toronto, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.