SPECIFICATIONS

| Model | TP-PF-C21 | TP-PF-C22 |

| Control System | PLC & Touch Screen | PLC & Touch Screen |

| Hopper | 25L | 50L |

| Packing Weight | 1 - 500g | 10 - 5000g |

| Weight Dosing | By Auger | By Auger |

| Packing Accuracy | ≤ 100g, ≤±2%; 100 – 500g, ≤±1% | ≤ 100g, ≤±2%; 100 – 500g,≤ ±1%; ≥500g, ≤±0.5% |

| Filling Speed | 40 – 120 times per min | 40 – 120 times per min |

| Power Supply | 3P AC208-415V, 50/60Hz | 3P AC208-415V 50/60Hz |

| Total Power | 1.2 KW | 1.6 KW |

| Total Weight | 300kg | 500kg |

| Packing Dimensions | 1180*890* 1400mm | 1600×970×2300mm |

ACCESSORIES LIST

| Model | TP-PF-B12 |

| Control system | PLC & Touch Screen |

| Hopper | Quick disconnecting hopper 100L |

| Packing Weight | 10kg – 50kg |

| Dosing mode | With online weighing; Fast and slow filling |

| Packing Accuracy | 10 – 20kg, ≤±1%, 20 - 50kg, ≤±0.1% |

| Filling Speed | 3– 20 times per min |

| Power Supply | 3P AC208-415V 50/60Hz |

| Total Power | 3.2 KW |

| Total Weight | 500kg |

| Overall Dimensions | 1130×950×2800mm |

Configuration List

| No. | Name | Pro. | Brand |

| 1 | Touch Screen | Germany | Siemens |

| 2 | PLC | Germany | Siemens |

| 3 | Servo Motor | Taiwan | Delta |

| 4 | Servo Driver | Taiwan | Delta |

| 5 | Load Cell | Switzerland | Mettler Toledo |

| 6 | Emergency Switch | France | Schneider |

| 7 | Filter | France | Schneider |

| 8 | Contactor | France | Schneider |

| 9 | Relay | Japan | Omron |

| 10 | Proximity Switch | Korea | Autonics |

| 11 | Level Sensor | Korea | Autonics |

DETAILED PHOTOS

1. Type change

Can change the automatic type and

semi-automatic type flexible at the same machine.

Automatic Type: without bottle stoppers, easy to adjust

Semi-automatic Type: with scale

2. Hopper

Level Split Hopper

Flexible change type, very easy to open the hopper and clean.

3. The way to fix Auger Screw

Screw Type

It will not make material stock, and easy for cleaning.

4. Processing

Full Welding

Easy to clean, even hopper side.

5. Air Outlet

Stainless Steel type

It is easy for cleaning and beautiful.

6. Level Sensor (Autonics)

It gives signal to loader when material lever is low, it does feed automatically.

7. Hand Wheel

It is suitable for filling into

bottles/bags with different height.

8. Leakproof Acentric Device

It is suitable for filling products with very good fluidity, such as, salt, white sugar etc.

9. Auger Screw and Tube

To make sure filling accuracy, one size screw is suitable for one weight range, for example, dia. 38mm screw is suitable for filling 100g-250g.

10. package size is smaller

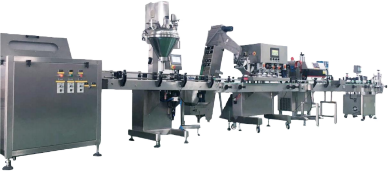

SEMI-AUTOMATC PACKING LINE

ribbon mixer + screw feeder + auger filler

ribbon mixer + screw conveyor + storage hopper + screw conveyor + auger filler+sealing machine

AUTOMATIC PACKING LINE

CERTIFICATES