Good quality Ribbon Type Mixer - Double Ribbon Mixer – Shanghai Tops Detail:

Main features

1. With CE certification.

2. About cover, we use bending strengthening process, it can reduce the weight of lid and at same time, it can keep the strength of lid.

3. About the 4 corners of lid, we make the round corner design, the advantage is there is no dead ends for cleaning and more beautiful.

4. Silicone sealing ring, very good sealing effect, no dust comes out when mixing.

5. Safety grid. It has 3 function:

A. Safety, to protect the operator and avoid personnel Injury.

B. prevent foreign matter from falling into. Such as, when you load with a big bag, it will prevent bags falling into the mixing tank.

C. If your product has large caking, the grid can break it.

6. About Material. All stainless steel 304 material. Food grade. It also can be made of stainless steel 316 and 316L if you require.

A.Full stainless-steel material. Food grade, very easy for cleaning.

B. Inside the tank, it is fully mirror polished for inside tank as well as shaft and ribbons. Very easy for cleaning.

C. Outside the tank, we use full weld technology, there is no powder left in welding gap. Very easy for cleaning.

7. No screws. Full Mirror polished inside of mixing tank, as well as ribbon and shaft, which is easy to clean as full welding. Powder mixer machine and main shaft are a whole one, no screws, no need to worry that screws may fall into the material and pollute the material.

8. Safety switch, the mixer stops running as soon as the lid is opened. it protects the personal safety of operators.

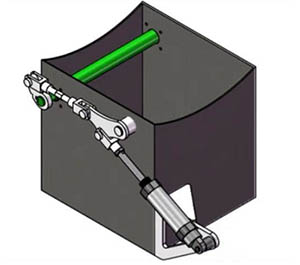

9. Hydraulic strut: open the lid slowly, with long life.

10. Timer: you can set the mixing time, it can be set from 1-15minutes, it depends on the product and mixing volume.

11. Discharge hole: two choice: manual and Pneumatic. We suggest using pneumatic discharge if there is air supply in factory. It is much easier to operate, here is the discharge switch, turn it on, the discharge flap opens. The powder will come out.

And, if you want to control flow, you use manual discharge.

12. Wheels for free moving.

Specification

| Model | TDPM 100 | TDPM 200 | TDPM 300 | TDPM 500 | TDPM 1000 | TDPM 1500 | TDPM 2000 | TDPM 3000 | TDPM 5000 | TDPM 10000 |

| Capacity(L) | 100 | 200 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 5000 | 10000 |

| Volume(L) | 140 | 280 | 420 | 710 | 1420 | 1800 | 2600 | 3800 | 7100 | 14000 |

| Loading rate | 40%-70% | |||||||||

| Length(mm) | 1050 | 1370 | 1550 | 1773 | 2394 | 2715 | 3080 | 3744 | 4000 | 5515 |

| Width(mm) | 700 | 834 | 970 | 1100 | 1320 | 1397 | 1625 | 1330 | 1500 | 1768 |

| Height(mm) | 1440 | 1647 | 1655 | 1855 | 2187 | 2313 | 2453 | 2718 | 1750 | 2400 |

| Weight(kg) | 180 | 250 | 350 | 500 | 700 | 1000 | 1300 | 1600 | 2100 | 2700 |

| Total Power (KW) | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | 45 | 75 |

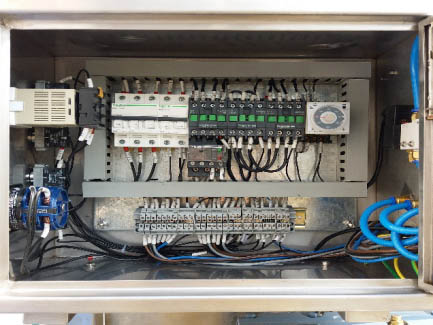

Configurations list

|

No. |

Name |

Brand |

|

1 |

Stainless steel |

China |

|

2 |

Circuit breaker |

Schneider |

|

3 |

Emergency switch |

Schneider |

|

4 |

Switch |

Schneider |

|

5 |

Contactor |

Schneider |

|

6 |

Assist contactor |

Schneider |

|

7 |

Heat relay |

Omron |

|

8 |

Relay |

Omron |

|

9 |

Timer relay |

Omron |

Detailed photos

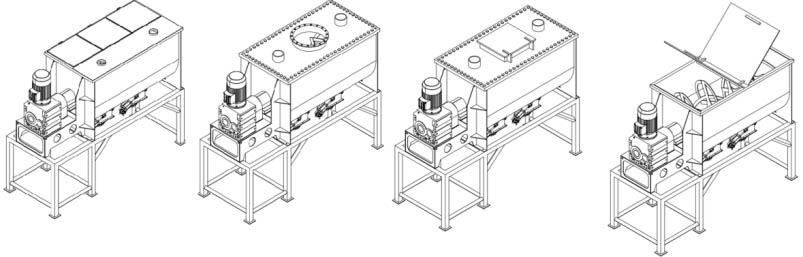

1. Cover

we use bending strengthening process, it can reduce the weight of lid and at same time, it can keep the strength of lid.

2. Round corner design

The advantage is there is no dead ends for cleaning and more beautiful.

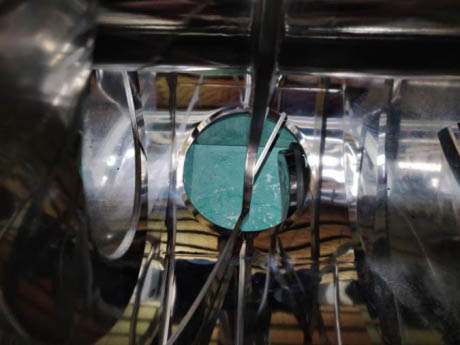

3. Silicone sealing ring

Very good sealing effect, no dust comes out when mixing.

4. Full welding & polished

The welding place of the machine are full welding, including the ribbon, the frame, the tank, etc. Mirror polished inside of the tank, no dead area, and easy to clean.

5. Safety grid

A. Safety, to protect the operator and avoid personnel Injury.

B. prevent foreign matter from falling into. Such as, when you load with a big bag, it will prevent bags falling into the mixing tank.

C. If your product has large caking, the grid can break it.

6. Hydraulic strut

Slow rising design keeps hydraulic stay bar long life.

7. Mixing time setting

There are “h”/”m”/”s”, it means hour, minute and seconds

8. Security switch

Safety device to avoid the personal injury, auto stop when mixing tank lid is opened.

9. Pneumatic discharge

We have patent certificate for this

discharge valve control device.

10. Curved flap

It’s not flat, it’s curved, it matches the mixing barrel perfectly.

Options

1. The barrel top cover of ribbon mixer can be customized according to different cases.

2. Discharge outlet

The dry powder mixer discharge valve can be driven manually or pneumatically. Optional valves: cylinder valve, butterfly valve etc.

3. Spraying system

Powder mixer blender consists of pump, nozzles, and hopper. a small amount of liquid can be mixed with powder materials with this system.

4. Double jacket cooling and heating function

This dry powder mixer machine also can be designed with the function to keep cold or heat. Add one layer outside the tank and put into medium into the interlayer to get the mixing material cold or heat. Usually use water for cool and hot steam of use electrical for heat.

5. Working platform and stair

Related machines

Application

1. Food industry

Food products, food ingredients,

food additives food processing AIDS in various fields,

and in the pharmaceutical intermediate, brewing,

biological enzymes, food packaging materials are also widely used.

2. Battery industry

Battery material, lithium battery anode

material, lithium battery cathode material,

carbon material raw material production.

3. Agricultural industry

Pesticide, fertilizer, feed and veterinary medicine, advanced pet food, new plant protection production, and in cultivated soil, microbial utilization, biological compost, desert greening, environmental protection industry also has a wide range of applications.

4. Chemical industry

Epoxy resin, polymer materials, fluorine materials, silicon materials, nanomaterials and other rubber and plastic chemical industry; Silicon compounds and silicates and other inorganic chemicals and various chemicals.

5. Comprehensive industry

Car brake material,

plant fiber environmental protection products,

edible tableware, etc

Production and processing

Factory shows

Shanghai Tops Group Co., Ltd. is professional manufacturer for powder and granular packaging systems.

We specialize in the fields of designing, manufacturing, supporting, and servicing a complete line of machinery for different kinds of powder and granular products, our main target of working is to offer the products which are related to the food industry, agriculture industry, chemical industry, and pharmacy field and more.

CE certificate

Service & Qualifications

■ One-year warranty, life-long service

■ Provide accessory parts in favorable price

■ Update configuration and program regularly

■ Respond to any question in 24 hours

FAQ

1. A re you a industrial powder mixer manufacturer?

Shanghai Tops Group Co., Ltd. is one of the leading ribbon mixer machine manufacturers in China, who has been in packing machine industry for over ten years. We have sold our machines to more than 80 countries all over the world.

Our company has a few invention patents of ribbon blender mixer design as well other machines.

We have abilities of designing, manufacturing as well customizing a single machine or whole packing line.

2. Does your small powder mixer machine have CE certificate?

Yes, we have horizontal ribbon mixer CE certificate. And not only small dry powder mixer, all our machines have CE certificate.

Moreover, we have some technical patents of milk powder mixer designs as well auger filler and other machines.

3. What products can milk powder mixer machine handle?

Vertical ribbon mixer can handle all kinds of powder or granule mixing and is widely applied in food, pharmaceuticals, chemical and so on.

Food industry: all kinds of food powder or granule mix like flour, oat flour, protein powder, milk powder, coffee powder, spice, chilli powder, pepper powder, coffee bean, rice, grains, salt, sugar, pet food, paprika, microcrystalline cellulose powder, xylitol etc.

Pharmaceuticals industry: all kinds of medical powder or granule mix like aspirin powder, ibuprofen powder, cephalosporin powder, amoxicillin powder, penicillin powder, clindamycin

powder, azithromycin powder, domperidone powder, amantadine powder, acetaminophen powder etc.

Chemical industry: all kinds of skin care and cosmetics powder or industry powder mix, like pressed powder, face powder, pigment, eye shadow powder, cheek powder, glitter powder, highlighting powder, baby powder, talcum powder, iron powder, soda ash, calcium carbonate powder, plastic particle, polyethylene etc.

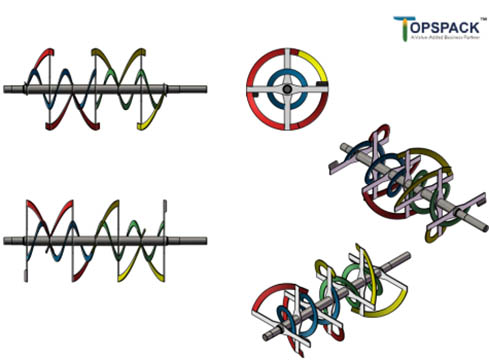

4. How do industry powder machine mixer work?

Double layer ribbons which stand and turn in opposite angels to form a convection in different materials so that it can reach a high mixing efficiency.

Our special design ribbons can achieve no dead angle in mixing tank.

The effective mixing time is only 5-10 minutes, even less within 3 min.

5. How to select a industrial ribbon mixer?

■ Select between ribbon and paddle blender

To select a small powder mixer, the first thing is to confirm if the commercial powder mixer is suitable.

Protein powder mixer is suitable for mixing different powder or granule with similar densities and which is not easy to break. It is not suitable for material which will melt or get sticky in higher temperature.

If your product is the mix consist of materials with very different densities, or it is easy to break, and which will melt or get sticky when temperature is higher, we recommend you to select the paddle mixer.

Because the working principles are different. Spiral ribbon mixer moves materials in opposite directions to achieve good mixing efficiency. But paddle mixer brings materials from tank bottom to top, so that it can keep materials complete and won’t make temperature go up during mixing. It won’t make material with larger density staying at tank bottom.

■ Choose a suitable model

Once confirm to use the small powder mixer machine, it comes into making decision on volume model. Machine mixer powder from all suppliers have the effective mixing volume. Normally it is about 70%. However, some suppliers name their models as total mixing volume, while some like us name our ribbon mixer blender models as effective mixing volume.

But most manufacturers arrange their output as weight not volume. You need to calculate the suitable volume according to your product density and batch weight.

For example, manufacturer TP produces 500kg flour each batch, whose density is 0.5kg/L. The output will be 1000L each batch. What TP needs is a 1000L capacity ribbon mixer blender. And TDPM 1000 model is suitable.

Please pay attention to the model of other suppliers. Make sure 1000L is their capacity not total volume.

■ Mixer ribbon blender quality

The last but the most important thing is to choose a ribbon type mixer with high quality. Some details as following are for reference where problems are most likely to occur on a double ribbon mixer.

About cover, we use bending strengthening process, it can reduce the weight of lid and at same time, it can keep the strength of lid.

About the 4 corners of lid, we make the round corner design, the advantage is there is no dead ends for cleaning and more beautiful.

Silicone sealing ring, very good sealing effect, no dust comes out when mixing.

Safety grid. It has 3 function:

A. Safety, to protect the operator and avoid personnel Injury.

B. prevent foreign matter from falling into. Such as, when you load with a big bag, it will prevent bags falling into the mixing tank.

C. If your product has large caking, the grid can break it.

About Material. All stainless steel 304 material. Food grade. It also can be made of stainless steel 316 and 316L if you require.

A. Full stainless-steel material. Food grade, very easy for cleaning.

B. Inside the tank, it is fully mirror polished for inside tank as well as shaft and ribbons. Very easy for cleaning.

C. Outside the tank, we use full weld technology, there is no powder left in welding gap. Very easy for cleaning.

No screws. Full Mirror polished inside of mixing tank, as well as ribbon and shaft, which is easy to clean as full welding. Double ribbons and main shaft are a whole one, no screws, no need to worry that screws may fall into the material and pollute the material.

Safety switch, the ribbon blender mixer machine stops running as soon as the lid is opened. it protects the personal safety of operators.

Hydraulic strut: open the lid slowly, with long life.

Timer: you can set the mixing time, it can be set from 1-15minutes, it depends on the product and mixing volume.

Discharge hole: two choice: manual and Pneumatic. We suggest using pneumatic discharge if there is air supply in factory. It is much easier to operate, here is the discharge switch, turn it on, the discharge flap opens. The powder will come out.

And, if you want to control flow, you use manual discharge.

Wheels for free moving.

Shaft sealing: test with water can show the shaft sealing effect. Powder leakage from shaft sealing always troubles users.

Discharge sealing: test with water also shows the discharge sealing effect. Many users have met leakage from discharge.

Full-welding: Full welding is one of the most important part for food and pharmaceutical machines. Powder is easy to hide in gap, which may pollute fresh powder if residual powder goes bad. But full-welding and polish can make no gap between hardware connection, which can show machine quality and usage experience.

Easy-cleaning design: A easy-cleaning helical ribbon mixer will save much time and energy for you which is equal to cost.

6 .What’s the ribbon mixer machine price?

The powder mixer machine price is based on capacity, option, customization. Please contact us to get your suitable powder mixer solution and offer.

7. Where to find a protein powder mixer machine for sale near me?

We have agents in Europe, USA.

Product detail pictures:

Related Product Guide:

Our advantages are reduced prices,dynamic product sales workforce,specialized QC,solid factories,superior quality services for Good quality Ribbon Type Mixer - Double Ribbon Mixer – Shanghai Tops, The product will supply to all over the world, such as: Ethiopia, Norway, Romania, In order to make more people know our products and to enlarge our market, we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!

-

China Wholesale Digital Control Particle Fillin...

-

Best High Quality Small Powder Blending Machine...

-

New Delivery for Twin Shaft Paddle Mixer - Dou...

-

China Wholesale Auger Filler Machine Manufa Fac...

-

Best High Quality Double Heads Auger Filler Fac...

-

Best High Quality Best Industrial Blender Facto...