Good User Reputation for Sugar Syrup Mixer - Paddle Mixer – Shanghai Tops Detail:

Video

Consist of

1. Mixer cover

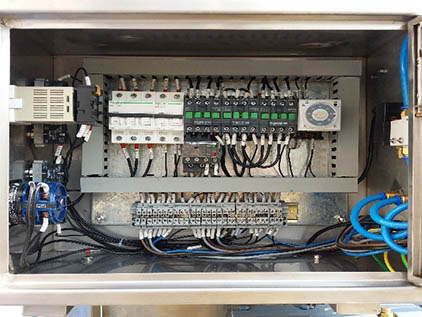

2. Electric Cabinet & Control Panel

3. Motor & reducer

4. Mixer hopper

5. Pneumatic valve

6. Legs and mobile caster

Descriptive abstract

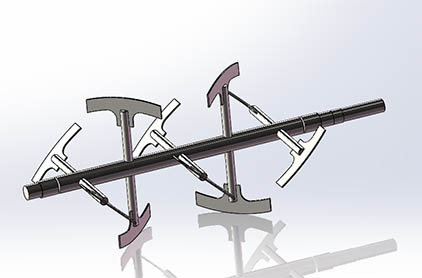

The single shaft paddle mixer is suitable use for powder and powder, granule and granule or add a little liquid to mixing, it is widely applied in nuts, beans, fee or other kinds of granule material, inside of the machine have different angle of blade thrown up the material thus cross mixing.

Working principle

Paddles throws material from mixing tank bottom to top from different angles

Features of paddle mixing equipment

1. Rotate reversely and throw materials to different angles, mixing time 1-3mm.

2. Compact design and rotated shafts be filled with hopper, mixing uniformity up to 99%.

3. Only 2-5mm gap between shafts and wall, open-type discharging hole.

4. Patent design and ensure the rotating axie & discharing hole w/o leakage.

5. Full weld and polishing process for mixing hopper, w/o any fastening piece like screw, nut.

6. The whole machine is made by 100%stainless steel to make its profile elegant except bearing seat.

Specification

|

Model |

WPS 100 |

WPS 200 |

WPS 300 |

WPS 500 |

WPS 1000 |

WPS 1500 |

WPS 2000 |

WPS 3000 |

WPS 5000 |

WPS 10000 |

|

Capacity(L) |

100 |

200 |

300 |

500 |

1000 |

1500 |

2000 |

3000 |

5000 |

10000 |

|

Volume(L) |

140 |

280 |

420 |

710 |

1420 |

1800 |

2600 |

3800 |

7100 |

14000 |

|

Loading rate |

40%-70% |

|||||||||

|

Length(mm) |

1050 |

1370 |

1550 |

1773 |

2394 |

2715 |

3080 |

3744 |

4000 |

5515 |

|

Width(mm) |

700 |

834 |

970 |

1100 |

1320 |

1397 |

1625 |

1330 |

1500 |

1768 |

|

Height(mm) |

1440 |

1647 |

1655 |

1855 |

2187 |

2313 |

2453 |

2718 |

1750 |

2400 |

|

Weight(kg) |

180 |

250 |

350 |

500 |

700 |

1000 |

1300 |

1600 |

2100 |

2700 |

|

Total Power (KW) |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

18.5 |

22 |

45 |

75 |

Accessories list

|

No. |

Name |

Brand |

|

1 |

Stainless steel |

China |

|

2 |

Circuit breaker |

Schneider |

|

3 |

Emergency switch |

Schneider |

|

4 |

Switch |

Schneider |

|

5 |

Contactor |

Schneider |

|

6 |

Assist contactor |

Schneider |

|

7 |

Heat relay |

Omron |

|

8 |

Relay |

Omron |

|

9 |

Timer relay |

Omron |

Detailed photos

1. Cover

There is bending strengthening on mixer lid design, which make the lid more strong and keep the weight less at the same time.

2. Round corner design

This design is high level and safer.

3. Silicone sealing ring

Silicone sealing can reach a good sealing effect and is easy to clean.

4. Full welding & polished

All hardware connection part is full welding including paddles, frame, tank, etc.

The whole inside part of the tank is mirror polished, which is no dead area, and easy to clean.

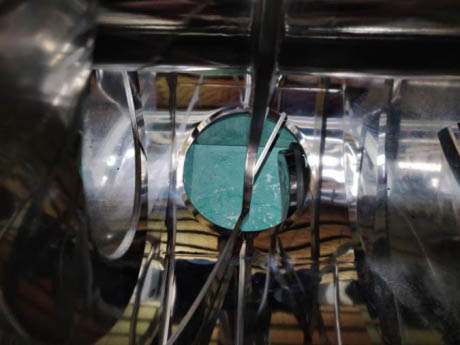

5. Safety grid

A. It is safer to protect the operator and is easy to operate loading with big bag.

B. Prevent foreign matter from falling into it.

C. If your product has large clumps, the grid can break it.

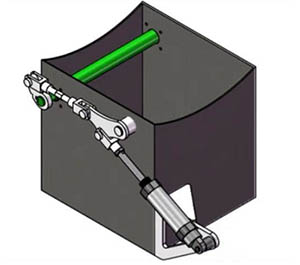

6. Hydraulic strut

Slow rising design keeps hydraulic stay bar long life.

7. Mixing time setting

There are “h”/”m”/”s”, it means hour, minute and seconds

8. Security switch

Safety device to avoid the personal injury, auto stop when mixing tank lid is opened.

9. Pneumatic discharge

We have patent certificate for this

discharge valve control device.

19. Curved flap

It’s not flat, it’s curved, it matches the mixing barrel perfectly.

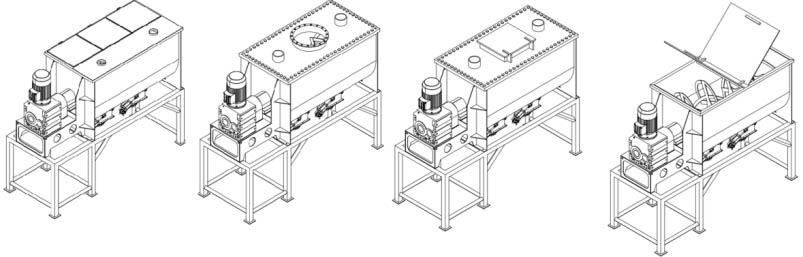

Options

1. Paddle mixer tank cover can be customized according to different conditions.

2. Discharge outlet

Paddle mixer discharge valve can be manually or pneumatically driven. Optional valve: cylinder valve, butterfly valve, etc.

3. Spraying system

Following mixer consists of a pump, a nozzle and a hopper. Small amounts of liquid can be mixed with powdery materials.

4. Double jacket cooling and heating function

This paddle mixer can also be designed with cold and hot functions.Add a layer in the tank, put the medium into the middle layer, make the mixed material cold or hot. It is usually cooled by water and heated by hot steam or electricity.

5. Working platform and stair

Related machines

Product detail pictures:

Related Product Guide:

The organization keeps on the procedure concept "scientific management, high quality and efficiency primacy, purchaser supreme for Good User Reputation for Sugar Syrup Mixer - Paddle Mixer – Shanghai Tops, The product will supply to all over the world, such as: USA, Kuwait, South Africa, Our products have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll provide the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.