Configurations List

|

No. |

Name |

Model Specification |

Region |

Brand |

|

1 |

Stainless Steel |

SUS304 |

|

|

|

2 |

Touch Screen |

|

Taiwan |

DELTA |

|

3 |

Servo Motor |

Driving Motor |

Taiwan |

DELTA |

|

4 |

Servo Driver |

|

Taiwan |

DELTA |

|

5 |

Contactor |

|

France |

Schneider |

|

6 |

Hot Relay |

|

France |

Schneider |

|

7 |

Relay |

|

France |

Schneider |

|

8 |

Level Sensor |

|

Germany |

PEPPERL+FUCHS |

Optional Device For Filler

A: Leakproof acentric device

B: Connector for dust-collector

Specification

|

Model |

TP-PF-A10N | TP-PF-A21N | TP-PF-A22N |

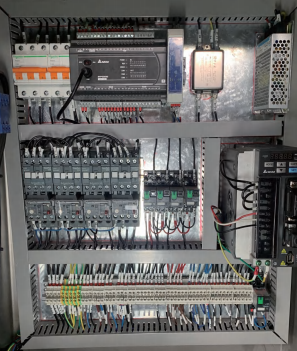

| Control system | PLC & Touch Screen | PLC & Touch Screen | PLC & Touch Screen |

| Hopper | 11L | 25L | 50L |

| Packing Weight | 1-50g | 1 - 500g | 10 - 5000g |

| Weight dosing | By auger | By auger | By auger |

| Packing Accuracy | ≤ 100g, ≤±2% | ≤ 100g, ≤±2%; 100 – 500g,

≤±1% |

≤ 100g, ≤±2%; 100 – 500g,

≤±1%; ≥500g,≤±0.5% |

| Filling Speed | 40–120 times per min | 40–120 times per min | 40–120 times per min |

| Power Supply | 3P AC208-415V

50/60Hz |

3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Total Power | 0.84 KW | 1.2 KW | 1.6 KW |

| Total Weight | 90kg | 160kg | 300kg |

| Overall

Dimensions |

590×560×1070mm |

1500×760×1850mm |

2000×970×2300mm |

Detailed Photos

1. Full stainless steel (SS304) split hopper - easy to open for convenient cleaning.

2. Level sensor - utilizing a tuning fork type level sensor from P+F brand, it is particularly suitable for various materials, especially those that are dusty in nature.

3. Feed inlet & air outlet - the feed inlet features a curved design to reduce impact on the hopper;

The air outlet is designed with a quick connection type, facilitating easier installation and disassembly.

4. Metering auger fixed in the hopper using a screw mechanism - prevents material buildup and facilitates easy cleaning.

5. Height-adjustment handwheel for the filling nozzle - designed for filling into bottles/bags of varying heights.

6. Our hopper is fully welded, making it easy to clean.

7. Our feeder wires are directly connected to the filler's plug, providing a simple, convenient, and safe setup.

8. Various sizes of metering augers and filling nozzles are provided to accommodate different filling weights and container openings with varying diameters.

9. Switch between two metering modes: volume and weighing metering, catering to different product requirements.

Other detailed photos

Bottle Unscrambling Machine + Screw Feeder + Auger Filler

Bottle Unscrambling Machine + Auger Filler+Capping Machine + Sealing Machine

Bottle Unscrambling Machine + Auger Filler+Capping Machine + Induction Sealing Machine + Labeling Machine

About Us

Shanghai Tops Group Co., Ltd is professional manufacturer for powder and granular packaging systems.

We specialize in the fields of designing, manufacturing, supporting and servicing a complete line of machinery for different kinds of powder and granular products, Our main target of working is to offer the products which are related to the food industry, agriculture industry, chemical industry, and pharmacy field and more.

We value our customers and are dedicated to maintaining relationships to ensure continued satisfaction and create win-win relationship. Let’s work hard altogether and make much greater success in the near future!

Our Team

Exhibition & Customer

Certificates