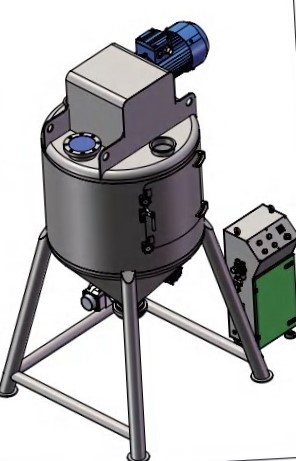

1. A single ribbon shaft, a vertically oriented tank, a drive unit, a cleanout door, and a chopper make up the vertical ribbon mixer.

2. It is a recently developed mixer that has been well-liked in the food and pharmaceutical sectors because of its simple structure, ease of cleaning, and thorough discharge capabilities.

3. The material is raised from the mixer's bottom by the ribbon agitator, which then permits gravity to take its course. Furthermore, a chopper is positioned on the vessel's side to break up agglomerates while mixing.

4. Complete cleaning of the mixer's interior is made easier by the cleanout door on the side.

5. There is zero probability that oil could leak into the mixer because the drive unit's components are all located outside of it.

6. The mixture is homogeneous and free of dead angles since there are no dead angles at the bottom.

The stirring mechanism and the copper wall have a tiny space between them that effectively prohibits material adherence.

7. A consistent spray effect is guaranteed by the highly sealed design, and the products meet GMP requirements.

8. The implementation of internal stress reduction technology leads to decreased maintenance expenses and steady system operation.

9. Outfitted with feeding limit alerts, overload prevention, automated operating timing, and other features.

10. The anti-sport design with an interrupted wire rod improves mixing uniformity and shortens mixing time.

Post time: Dec-05-2023