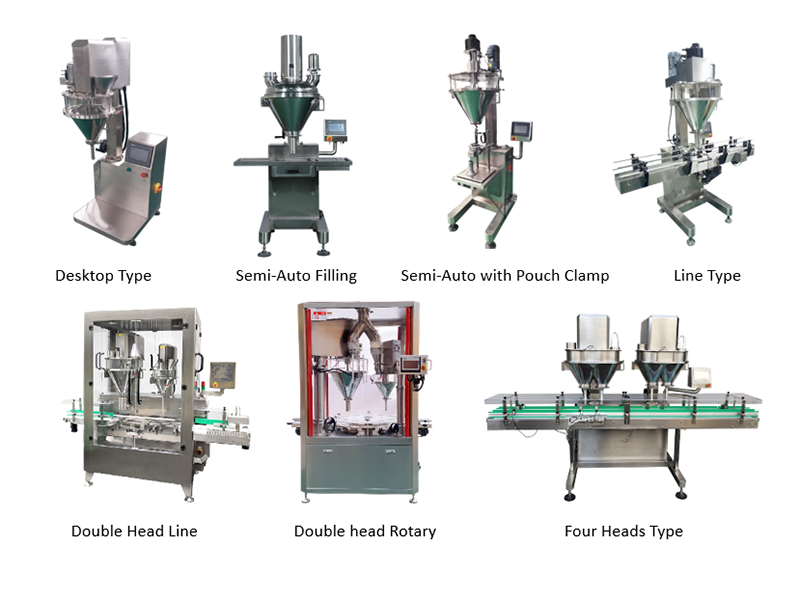

1. There are several model options available. You can select the model that best suits your product.

2. Auger filling is both automatic and semi-automated. You can select auto or semi-auto for your products.

3. Servo motor: To achieve high filling weight precision, we apply a Taiwan-made Delta servo motor to regulate the auger. One can designate the brand.

A servomotor is a linear or rotary actuator that enables accurate control over acceleration, velocity, and angular position. It consists of a suitable motor connected to a position-feedback sensor. It also needs a rather complex controller, which is usually a specialized module made just for servomotor applications.

4. Central components: The area of greatest importance for auger filler is the central component of the auger.

Tops Group does well in assembly, precision processing, and central components. Although processing precision and assembly are unnoticeable to the unaided eye and cannot be intuitively compared, it will become evident in use.

5. High concentricity: If the auger and shaft don't have a high degree of concentricity, the accuracy won't be excellent.

Between the servo motor and auger, we make use of a shaft from a globally renowned brand.

6. Precision machining: To produce a small-sized auger with consistent dimensions and an extremely precise form, Tops Group uses a milling machine.

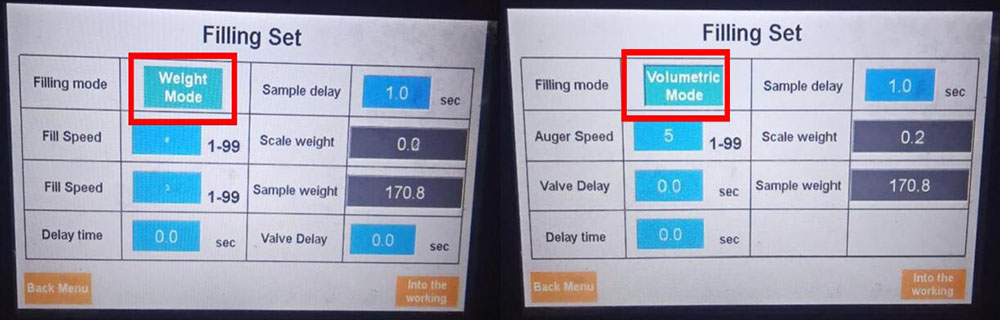

7. Two filling modes—volume and weight—are interchangeable.

Volume mode:

The powder volume reduced by one cycle of screw rotation is constant. The number of revolutions the screw has to make to obtain the desired filling weight will be determined by the controller.

Weight mode:

A load cell beneath the filling plate measures the filling weight in real time. To achieve 80% of the goal filling weight, the first filling is quick and heavy.

The second filling, which supplements the remaining 20% based on timely filling weight, is precise and gradual.

Post time: Nov-13-2023