What exactly is an auger filler packing machine?

The machine incorporates cutting-edge European packaging technology concepts, and the design is more reasonable, stable, and dependable. We increased the original eight stations to twelve. As a result, the single rotation angle of the turntable has been greatly reduced, significantly improving running speed and stability. The equipment can automatically handle jar feeding, measuring, filling, weighing feedback, automatic correction, and other tasks. It can be used to fill powdered materials such as milk powder, for example.

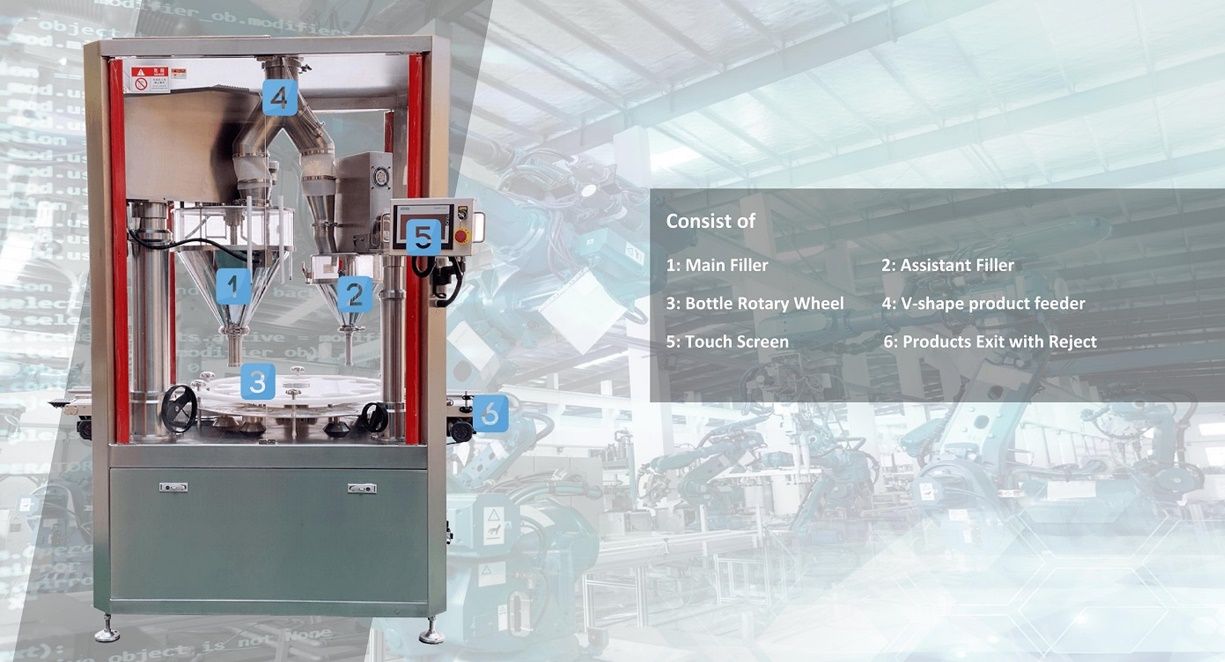

The Composition of Auger Filler Packing Machine

The Specification

|

Measurement method |

second supplement after filling |

|

Container size |

cylindrical container φ50-130 (replace the mold) 100-180mm high |

|

Packing weight |

100-1000g |

|

Packaging accuracy |

≤± 1-2G |

|

Packaging speed |

≥40-50 jars/min |

|

Power supply |

three-phase 380V 50Hz |

|

Machine power |

5kw |

|

Air pressure |

6-8kg/cm2 |

|

Gas consumption |

0.2m3/min |

|

Machine weight |

900kg |

|

A set of canned molds will be sent along with it |

|

Principle

Two fillers, one for fast and 80% target weight filling and the other for gradually supplementing the remaining 20%.

Two load cells are used: one after the fast filler to determine how much weight the gentle filler needs to supplement, and the other after the gentle filler to remove reject.

How Does a Filler with Two Heads Work?

1. The main filler will quickly reach the target weight of 85%.

2. The assistant filler will precisely and gradually replace the left 15%.

3. They work together to achieve high speed while maintaining high precision.

Application

Regardless of the application, it can help a wide range of industries in many ways.

Food Industry - milk powder, protein powder, flour, sugar, salt, oat flour, etc.

Pharmaceutical Industry – aspirin, ibuprofen, herbal powder, etc.

Cosmetic Industry – face powder, nail powder, toilet powder, etc.

Chemical Industry – talcum powder, metal powder, plastic powder, etc.

Connects to Other Machines

To meet varying production requirements, the auger filler can be combined with various machines to create a new working mode.

It works with other pieces of equipment in your line, such as cappers and labelers.

Installation and upkeep: When you receive the machine, all you need to do is unpack the crates and connect the machine's power source, and it will be ready to use. Machines can be programmed to work for any user.

-Add a small amount of oil every three or four months. After filling up materials, clean the auger filler packing machine.

Post time: Sep-21-2022