This automatic rotary type has a unique design that makes it suitable for dosing and filling work with fluidic or low-fluidity materials such as coffee powder, wheat flour, condiment, solid drink, veterinary drugs, dextrose, pharmaceuticals, powder additive, talcum powder, agricultural pesticide, dyestuff, and so on.

Main Features:

• Simple to clean. Structure is made of stainless steel.

• Consistent and dependable performance. The auger is driven by a servomotor, and the turntable is controlled by a servomotor.

• It is simple to use. Control is provided by a PLC, a touch screen, and a weighing module.

• Equipped with a pneumatic can lifting device to prevent spillage when filling an on-line weighing device

• Weight-selected device, to ensure that each product is qualified and to eliminate unqualified filled cans.

• With an adjustable height-adjustment hand wheel at a reasonable height, adjusting the head position is simple.

• Save 10 formula sets inside the machine for later use.

• When the auger parts are replaced, different products ranging from fine powder to granules and different weights can be packed. One stir on the hopper ensures that the powder fills the auger.

• Touch screen in Chinese/English or your preferred language.

• Reasonable mechanical structure, simple size changes, and cleanup.

• By changing the accessories, the machine can be used for a variety of powder products.

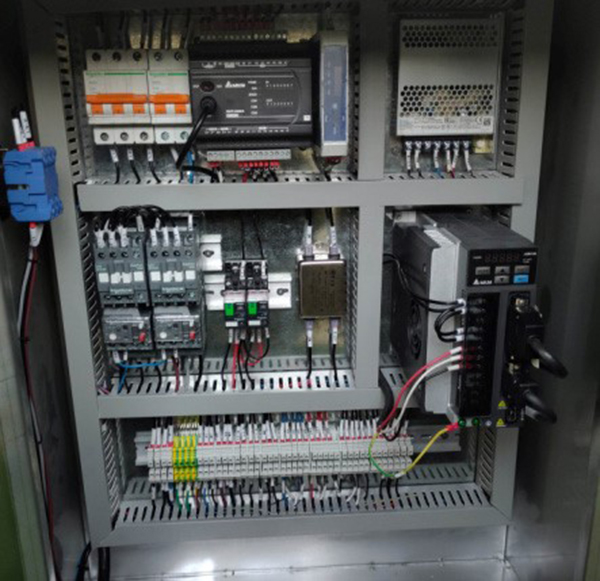

• We use the well-known Siemens PLC, Schneider Electric, which is more stable.

Specification

|

Model |

TP-PF-A31 |

TP-PF-A32 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

35L |

50L |

|

Packing Weight |

1-500g |

10 - 5000g |

|

Weight dosing |

By auger |

By auger |

|

Container size |

Φ20~100mm ,H15~150mm |

Φ30~160mm ,H50~260mm |

|

Packing Accuracy |

≤ 100g, ≤±2% 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% ≥500g,≤±0.5% |

|

Filling Speed |

20 – 50 times per min |

20 – 40 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

1.8 KW |

2.3 KW |

|

Total Weight |

250kg |

350kg |

|

Overall Dimensions |

1400*830*2080mm |

1840×1070×2420mm |

Configuration List

|

No. |

Name |

Pro. |

Brand |

|

1 |

PLC |

Taiwan |

DELTA |

|

2 |

Touch Screen |

Taiwan |

DELTA |

|

3 |

Servo motor |

Taiwan |

DELTA |

|

4 |

Servo driver |

Taiwan |

DELTA |

|

5 |

Switching powder |

|

Schneider |

|

6 |

Emergency switch |

|

Schneider |

|

7 |

Contactor |

|

Schneider |

|

8 |

Relay |

|

Omron |

|

9 |

Proximity switch |

Korea |

Au tonics |

|

10 |

Level sensor |

Korea |

Au tonics |

Accessories

|

No. |

Name |

Quantity |

Remark |

|

1 |

Fuse |

10pcs |

|

|

2 |

Jiggle switch |

1pcs |

|

|

3 |

1000g Poise |

1pcs |

|

|

4 |

Socket |

1pcs |

|

|

5 |

Pedal |

1pcs |

|

|

6 |

Connector plug |

3pcs |

Toolbox

|

No. |

Name |

Quantity |

Remark |

|

1 |

Spanner |

2pcs |

|

|

2 |

Spanner |

1set |

|

|

3 |

Slotted screwdriver |

2pcs |

|

|

4 |

Phillips screwdriver |

2pcs |

|

|

5 |

User manual |

1pcs |

|

|

6 |

Packing list |

1pcs |

Air outlet with quick connection type

For more convenient installation and dis-assembly.

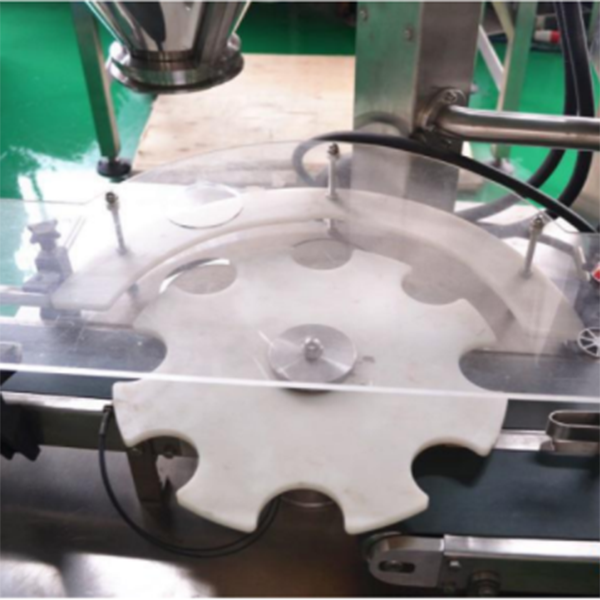

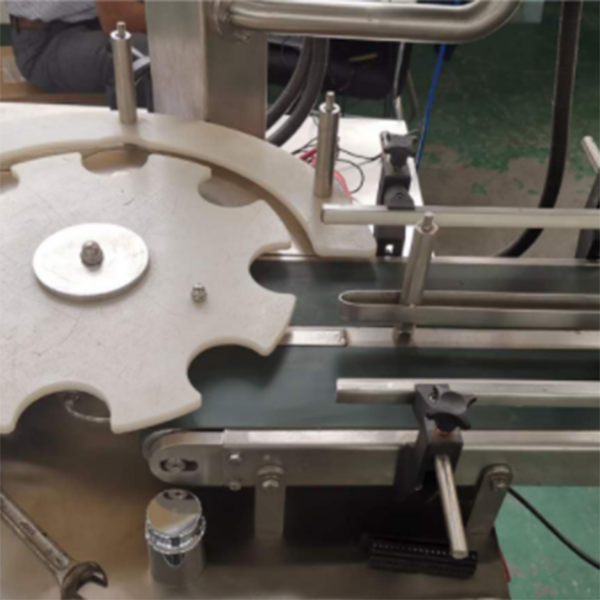

Rotary Plate

Can/bottle placing with a rotary plate is easier and more convenient than with a straight line.

Two output belts

One belt collects weight qualified bottles, while the other belt collects weight unqualified bottles.

Filling Products Samples:

Related Machines:

Screw Feeder

Bag Sealing Machine

Dust Collector

Ribbon Mixer

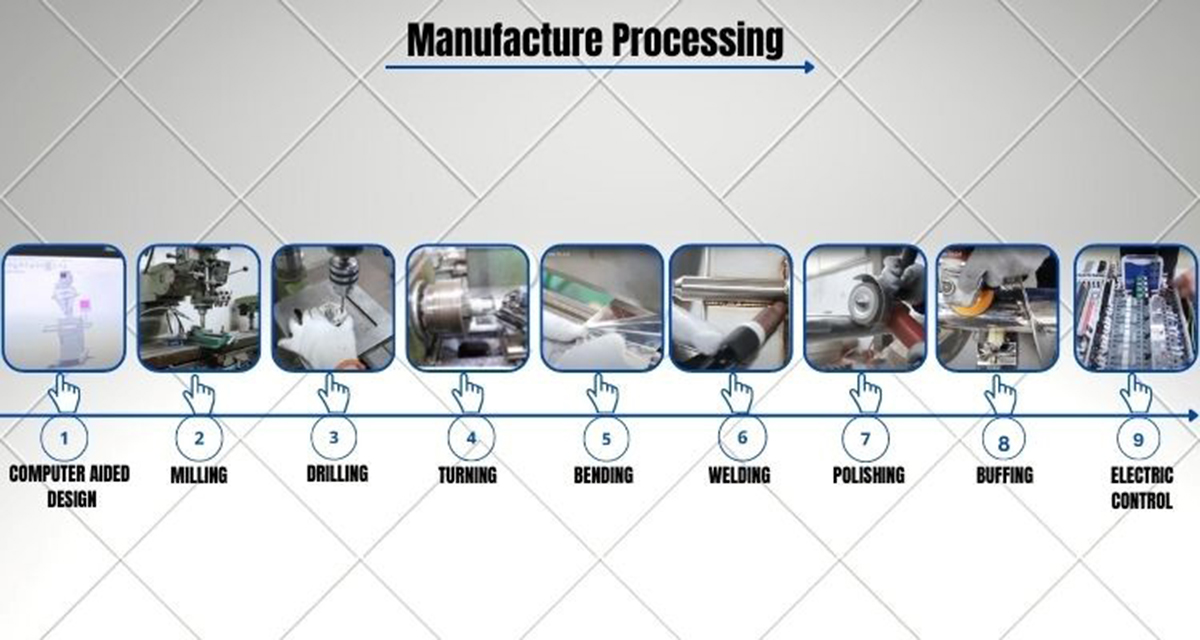

We the Shanghai Tops Group Company manufactured different types of auger filler. We ensure to provide high quality machines as well as advanced technology of auger filler.

Post time: Jan-13-2023