This big bag type model is primarily for fine powders that quickly spew dust and demand high-accuracy packing. This machine does measurement, two-filling, and up-down work etc. Based on the feedback signal provided by the weight sensor below. It's ideal for filling additives, carbon powder, fire extinguisher dry powder, and other fine powders that require packing accuracy.

Main Features:

-To ensure exact filling accuracy, we use a lathing auger screw.

-To ensure consistent performance, a servo motor powers the screw.

- With PLC control and touch screen display.

-The materials are full stainless steel 304 and glass.

-The quick disconnecting hopper is easy to wash without the use of any tools.

-Varying materials ranging from fine powder to granules and different weights can be packed by replacing the auger pieces.

-Weight feedback and proportion track to materials, which overcomes the challenges of filling weight changes because of the density fluctuations in materials.

-Save 10 sets of formula inside the machine for later use

-Varying materials ranging from fine powder to granules and different weights can be packed by replacing the auger parts.

-The weight sensor is located below the tray, allowing for fast and slow filling based on the pre-set weight, ensuring high package accuracy.

-Process: put bag/can (container) on the machine → container raise → fast filling container declines → weight reaches the pre-set number → slow filling → weight reaches the goal number → take the container away manually

Specifications

| Model | TP-PF-B11 | TP-PF-B12 |

| Control system | PLC & Touch Screen | PLC & Touch Screen |

| Hopper | Quick disconnecting hopper 100L | Quick disconnecting hopper 100L |

| Packing Weight | 1-10kg | 1-50kg |

| Dosing mode | With online weighing; Fast and slow filling | With online weighing; Fast and slow filling |

| Packing Accuracy | 1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% | |

| Filling speed | 2– 25 times per min | 2– 25 times per min |

| Power supply | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Total power |

3.2 KW |

3.2 KW |

| Total weight |

500kg |

|

| Overall Dimensions | 1130×950×2800mm |

Metering auger: different metering range use different size auger

Two kinds of hopper are available for choice

Quick disconnecting hopper

Level split hopper

Centrifugal device

It is easy flowing products just to ensure the precise filling accuracy.

Pressure forcing device

It is non-flowing to ensure product, the precise filling accuracy.

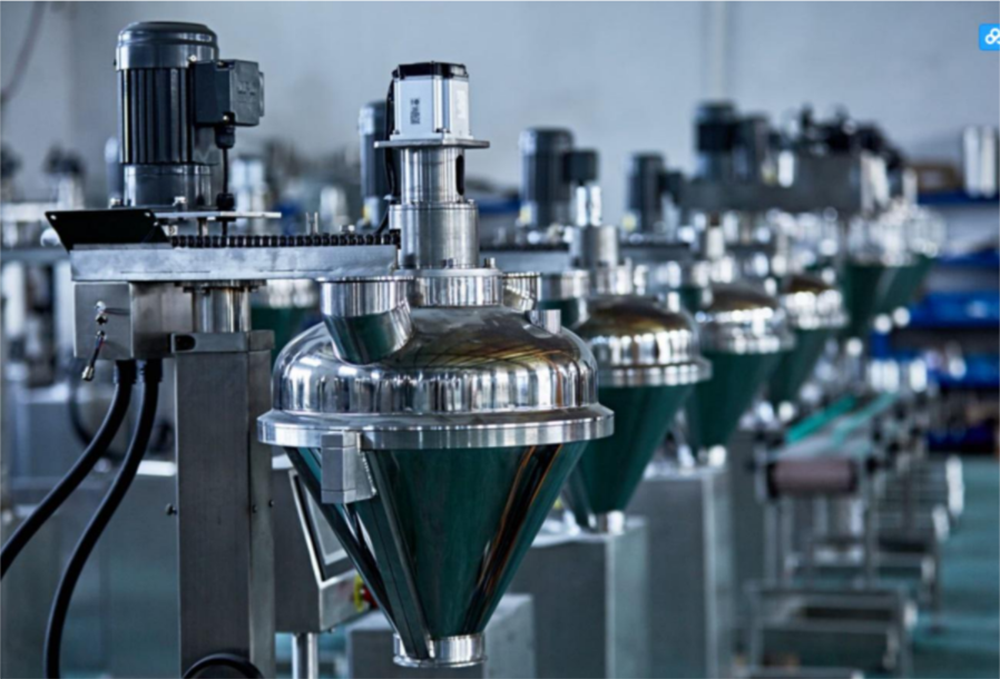

Production and Processing

Factory Show

Exhibitions

Certificates

Service & Qualifications

■ Warranty: TWO YEAR warranty

ENGINE THREE YEARS warranty

Life-long service

(Warranty service will be honored if the damage is not caused by human or improper operation)

■ Provide accessory parts in favorable price

■ Update configuration and program regularly

■ Respond to any question in 24 hours

■ Payment Term: L/C, D/A, D/P, T/T, Western Union, Money Gram, PayPal

■ Price Term: EXW, FOB, CIF, DDU

■ Package: cellophane cover with wooden case.

■ Delivery Time: 7-10 days (standard model)

30-45days (customized machine)

■ Note: V Blender shipped by air is about 7-10 days and 10-60 days by sea, it depends on a distance.

■Place of Origin: Shanghai China

Post time: Jan-17-2023