The Tops Group China Ribbon Mixer Machine is introduced as follows:

Tops Group's primary focus is to provide products related to the food, agriculture, chemical, and pharmacy industries, among others. The company specializes in designing, manufacturing, supporting, and servicing an entire range of machinery for various types of powder and granular products.

A solution for blending powders, powder with liquid, powder with granules, and even the tiniest amount of components is the China Ribbon Mixer Machine. Its horizontal U-shaped design and whirling agitator give it a distinctive appearance. The outer ribbon pushes the materials from the two sides to the center and the inner ribbon pushes the material from the center to both sides.

Application:

Safety devices:

The safety grid, safety switch, and safety wheels are its three safety features. These three safety devices serve the purpose of protecting users from hazards.

A safety grid guards against foreign objects falling into a tank and safeguarding the operator while they are functioning as well. Safety wheels allow the machine to be moved with ease, and the safety switch ensures the operator's safety as well.

It can be customized according to the customers required:

Many options:

Barrel Top Cover

-The top cover of blender can also be customized, and the discharge valve can be manually or pneumatically driven.

Types of valves

-It has optional valves: cylinder valve, butterfly valve etc.

Additional Functions

-Customer can also require the blender to equipped additional function with a jacket system for heating and cooling system, weighing system, dust removal system and spray system. It has a spraying system for liquid to blend in a powder material. This blender has the cooling and heating function of a double jacket, and it could be intended to keep the mixing material warm or cold.

Speed Adjustment

-It can also customize speed adjustable, by installing a frequency converter; the ribbon mixer can be adjusted to the speed.

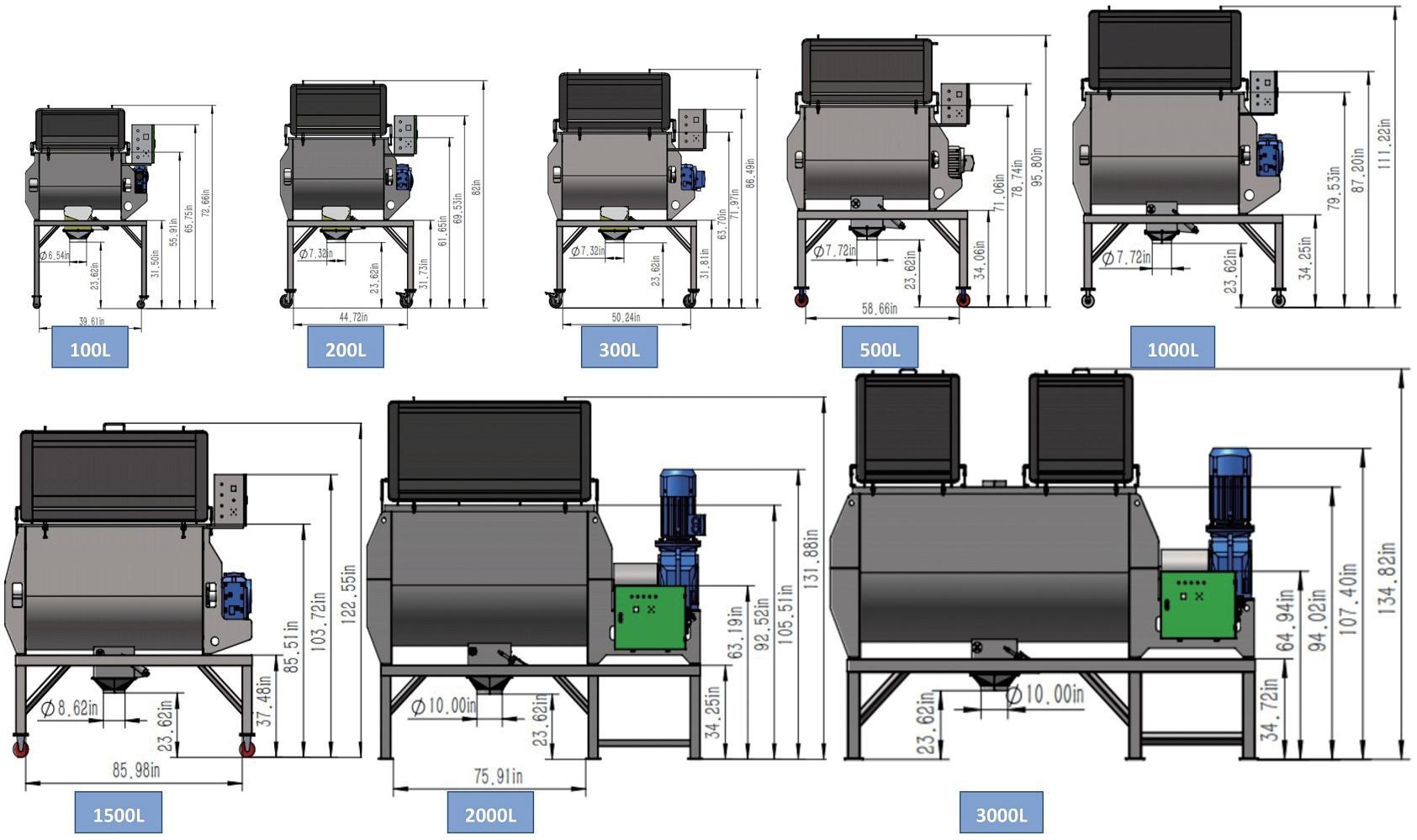

China Ribbon Mixer Machine Sizes

- It is composed of different sizes and customers can choose according to their required sizes.

Loading System

-It has automated loading system and there are three types of conveyors. The vacuum loading system is better suited for loading at high height. The Screw conveyer is not suited for granule or easy-break material however it is suitable for working shops which have limited height. The bucket conveyor is suitable for granule conveyor. The blender is best suited for powders and materials with a high or low density, and it requires more force during mixing.

Production Line

-In comparison with manual operation, the production line saves a lot of energy and time. To supply enough material in due time, the loading system will connect two machines. The machine manufacturer tells you that it takes you less time and improves your efficiency.

Post time: Aug-02-2024