A double paddle mixer is also known as a no-gravity mixer. It's commonly used to combine powder and powder, granular and granular, granular and powder, and a few liquids. It has a high-precision mixing machine that responds to mixing and properly mixes ingredients with different gravities, proportions, and particle sizes. It produces portion fragmentation by adding fragmentation equipment.

Double jacket cooling and heating function

Spray System

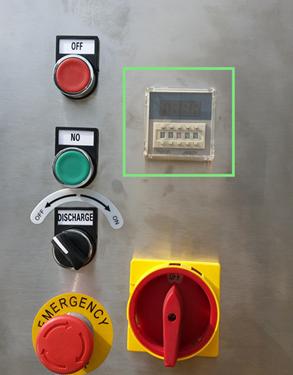

Time Settings

The mixing time selections on the double paddle mixer are "hours, minutes, and seconds."

Speed Adjustment

The speed of the double paddle mixer can also be customized by adding a frequency converter. You can adjust the time based on the material and mixing method.

The spray system for liquid applied to dry materials can also be customized with a double paddle mixer. It is made up of a pump, nozzles, and a hopper. With this technique, a small amount of liquid can be blended with powdered materials.

Working Platform

The cooling and heating functions of the double paddle mixer can also be customized. This function is intended to keep the cold or heat in.

Add one layer outside the tank and place it in the interlayer to get the mixing material cold or hot. Water is typically applied to generate both cool and hot steam, whereas electricity is used to generate heat.

Filtering system and barometer

The quick plug interface is directly connected to the air compressor.

Working on the double paddle mixer required the use of stairs.

Application:

Double shaft paddle mixer is commonly used in industries such as:

Food industry- food products, food ingredients, food additives food processing AIDS in various fields, and in the pharmaceutical intermediate, brewing, biological enzymes, food packaging materials are also widely used.

Agricultural industry- Pesticide, fertilizer, feed and veterinary medicine, advanced pet food, new plant protection production, and in cultivated soil, microbial utilization, biological compost, and desert greening.

Chemical industry- Epoxy resin, polymer materials, fluorine materials, silicon materials, nanomaterials and other rubber and plastic chemical industry; Silicon compounds and silicates and other inorganic chemicals and various chemicals.

Battery industry- Battery material, lithium battery anode material, lithium battery cathode material and carbon material raw material production.

Comprehensive industry- Car brake material, plant fiber environmental protection products, edible tableware, etc.

Post time: Jul-25-2022