Are you looking for a filling machine for your products?

Do you want to have different capacities and structures?

Shanghai Tops Group is a filling machine manufacturer with a patent on the appearance of servo auger fillers. This machine can both dose and fill. It is suitable for use with fine granular materials, low-fluidity materials, and other materials.

Application:

Industries like:

1.Construction 5. Chemical

2.Pharmaceutical 6. Agriculture and many more

3.Food

4.Plastic

Tops Group filling machines can be customized to satisfy your specific requirements.

Let's find out the different types and the details:

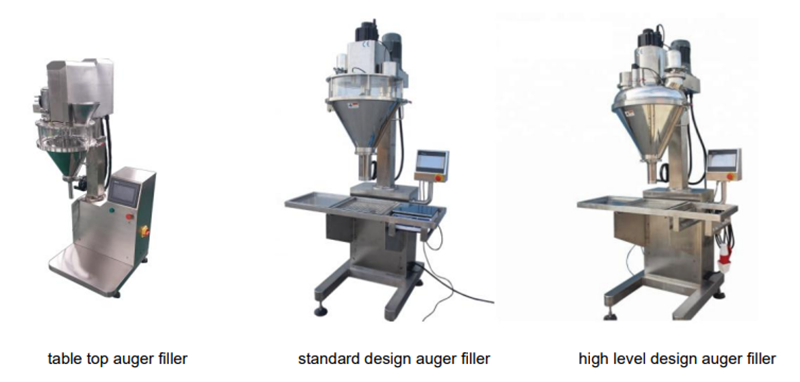

The semi-auto filling machine is an expert at low-speed filling. It can handle both bottles and pouches because the operator must manually arrange bottles on a plate beneath the filler and move them away after filling. The hopper can be entirely constructed of stainless steel. Furthermore, the sensor could be a tuning fork or a photoelectric sensor. We have filling machines in three sizes: small, standard, and high-level.

Semi-auto Filling with Pouch Clamp

This pouch filling machine is a pouch-clamped semi-auto filling. The pouch clamp will automatically hold the bag after you stamp the pedal plate. When the bag is full, it will automatically release it. Because the TP-PF-B12 is a large model, it has a plate that raises and lowers the bag during filling to reduce dust and weight error. It has a load cell that detects actual weight; gravity will cause an error when the powder is poured from the end of the filler to the bottom of the bag. The plate elevates the bag, allowing the filling tube to enter. The plate falls gently as it fills.

Line-type Auto Filling for Bottles

The line-type auto-filling is commonly used in powder bottle filling. It can be connected to a powder feeder, powder mixer, capping machine, and labeling machine to create an automatic packing line. The bottle stopper holds back bottles so that the bottle holder can use the conveyor to lift the bottle under the filler. The conveyor automatically moves each bottle forward after they have been filled. It can handle all bottle sizes on a single machine, making it ideal for users with a variety of packaging dimensions. A halted stainless-steel hopper and a full stainless-steel hopper are optional features. There are two kinds of sensors on the market. It can also be customized to include online weighing for absolute accuracy.

Rotary Auto Filling

A high-speed rotary filling machine is used to fill bottles. Because the bottle wheel can only accommodate one diameter, this type of auger filler is best suited for customers with one or two-diameter bottles. The speed and accuracy are faster and more accurate than with a line-type auger filler. The rotary type is also capable of online weighing and rejection. In real-time, the filler will load powder based on the filling weight, and the rejection function will detect and remove disqualified weight. The machine cover is an optional extra.

Double Head Filling

A double-head filling is used to achieve high-speed filling. The highest possible speed is 100 beats per minute. Because of the high accuracy weight control, the check weighing and reject system prevents costly product waste. It is frequently used in the production of milk powder.

Powder Packing system

A powder packing machine is formed when the filling machine is combined with the packing machine. It can work with a roll film sachet filling and sealing machine, a micro doypack packing machine, a rotary pouch packing machine, or a premade pouch packing machine.

Detailed Parts:

The Hopper

Tops Group hoppers are level-split hoppers that are simple to open and clean.

Way to fix Auger Screw

We used a screw type that keeps materials in place and is also easy to clean.

Air Supply

316L stainless steel is used. It is both visually appealing and easy to clean.

Sensor Sensitivity (Au tonics)

When the material level is low, it sends a signal to the loader and automatically begins feeding.

The Steering Wheel

It can be poured into a variety of bottle or bag sizes.

Acentric's Leakproof System

It's perfect for filling products with high fluidity, such as salt or white sugar and more.

The Auger Screw and Tube

One size screw is suitable for one weight range to ensure filling accuracy. The 38mm screw is ideal for filling quantities ranging from 100g to 250g.

When Maintaining the Filling Machine:

•Add a small amount of oil every three or four months.

• Apply a small amount of grease to the stir motor chain every three or four months.

• After nearly a year, the sealing strip on both sides of the material bin may become brittle. Replace them if necessary.

• After nearly a year, the sealing strip on both sides of the hopper may begin to deteriorate. Replace them if necessary.

• Keep the material bin clean.

• Maintain a clean hopper.

All types of filling machines are efficient and beneficial to any industry that requires filling and dosing. Tops Group provides a variety of capacity models that can be customized to meet your needs.

Post time: Aug-24-2022