For today’s topic, let’s tackle the high processing technology of the V Mixer.

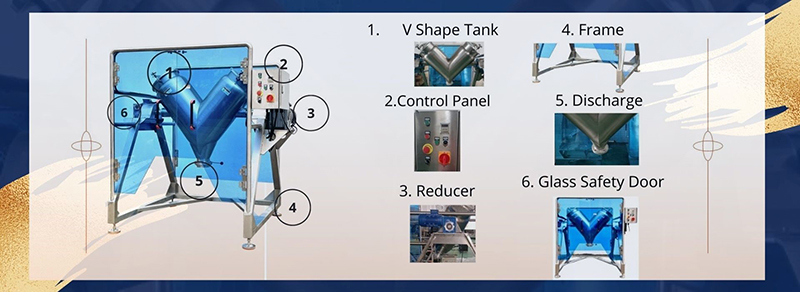

In the pharmaceutical, chemical, and food industries, the V mixer can mix more than two types of dry powder and granular materials. It can be equipped with a forced agitator according to the needs of the user, making it suited for mixing fine powder, cake, and materials with a particular amount of moisture. It has two openings on top of the “V” shaped tank that conveniently discharge the materials at the end of the mixing process, and it can produce a solid-solid mixture.

The V mixer is composed of:

Processing steps of V mixer:

1. The design of the connecting component of the barrel body

For fine-tuning to achieve high concentricity, there are four adjustable screw holes in addition to the fixing holes.

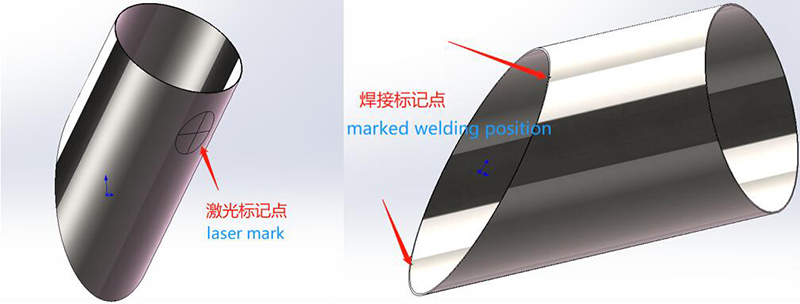

2. The laser is used to cut the entire cylinder. To avoid errors caused by measurement, a laser mark has been placed at the flange welding position.

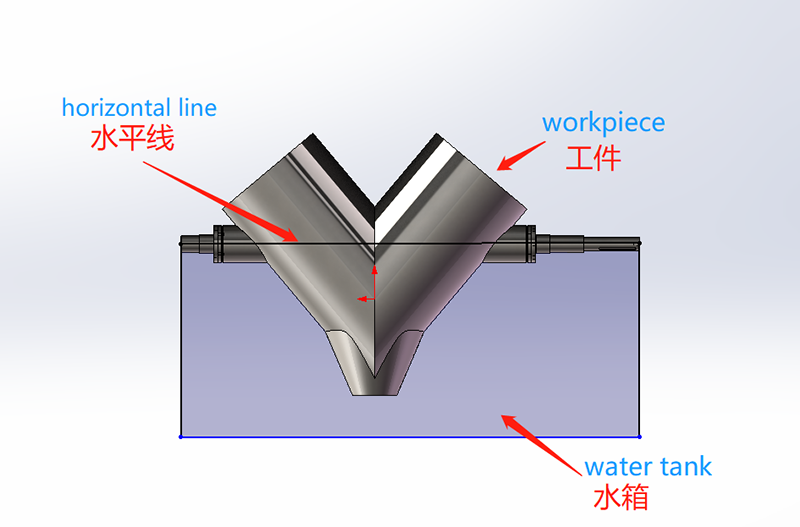

3. The water-cooling method prevents normal welding deformation.

4. Welding with the entire workpiece filled in water, ensuring that all ends are in the same horizontal line.

Post time: Mar-17-2022