Click the video: https://youtu.be/Kwab5jhsfL8

When selecting the best V-shaped mixer, keep the following factors in mind:

• The first step is to determine which product will be mixed in a V-shaped mixer.

The V-shaped mixer efficiently mixes more than two types of dry powder with more than 99% uniformity.

• The next step is to choose an appropriate model.

The next step is to create a volume model after deciding which model of V-shaped mixer to use. You must calculate the appropriate volume based on your product density and batch weight.

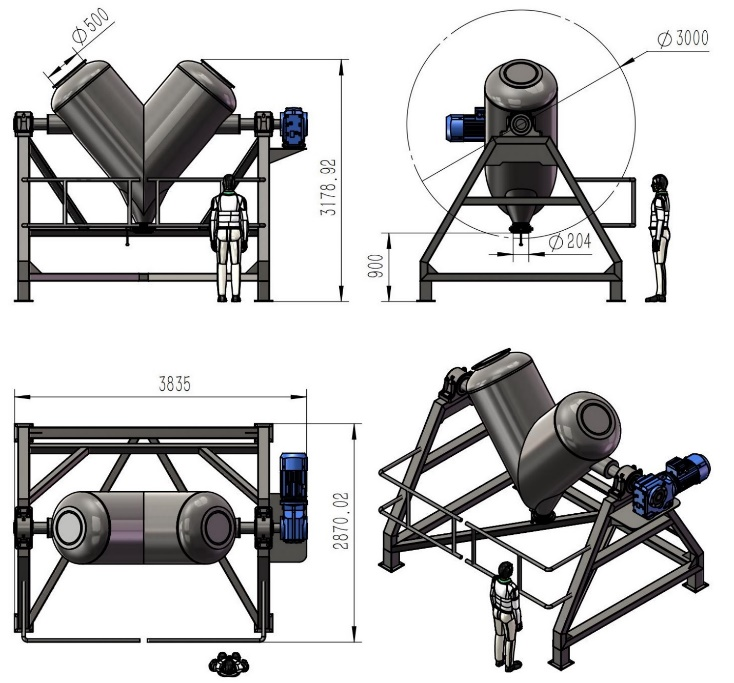

For example, 500L has 250L capacity, which is 125kg when the material density is 0.5kg/l.

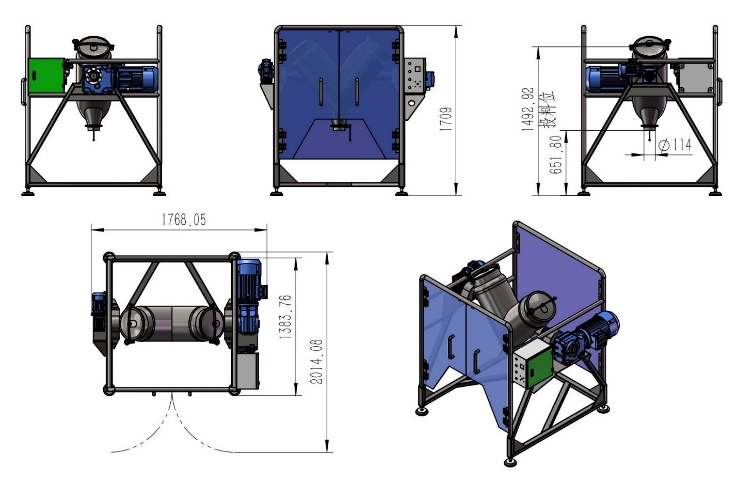

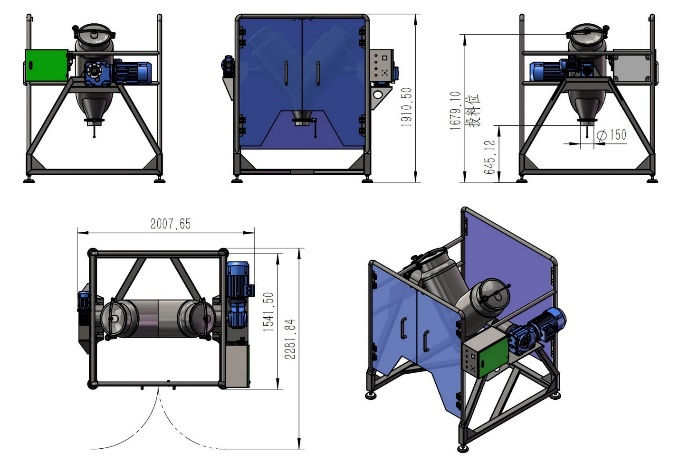

-V-shaped mixers come in a variety of models, including the TP-V 100, TP-V 200, TP-V 500, TP-V 1000, TP-V 1500, TP-V 2000, and TP-V 3000, and can be customized to your specifications.

• The quality of the V-shaped mixer is the most important factor for everyone.

The following are the qualities of a V-shaped mixer:

• There are no dead angles when discharging with discharge sealing.

• Full welding and mirror polished

In the food and pharmaceutical industries, powder is easy to hide in gaps, which may pollute fresh powder if residual powder goes bad. But full-welding and polishing can ensure no gap between hardware connections, which can show machine quality and usage experience.

• When cleaning the mixer, it is simple to clean. It is easier and less time-consuming to clean.

• Charging or feeding powder material to the V-shaped mixer provides convenience and satisfaction.

• Simple to use and ensures safe operation.

• With a two-cylinder structure, a mixing time of 8–10 minutes can achieve high efficiency and excellent mixing uniformity.

• A plexiglass safe door and a safety button keep the operator safe.

• All stainless steel 304 material, with an optional contact part of stainless steel 316, which is suitable for food-grade production and has a long service life.

Post time: Nov-14-2022