how does a ribbon blender work?

A lot of people are curious about how does a ribbon blender work? Will it operate well? Let's explore the operation how does a ribbon blender work in this blog post.

Ribbon blenders are commonly used in the chemical, pharmaceutical, food, and construction industries. It can be used to mix powders in different mixes, such as powder with liquid, powder with granules, and powder with powders. The double ribbon agitator operates under motor power and quickly achieves a high level of convective mixing.

The material from the two sides is pushed into the center by the outer ribbon.

The material is pushed from the center to both sides by the inner ribbon.

Principal attributes

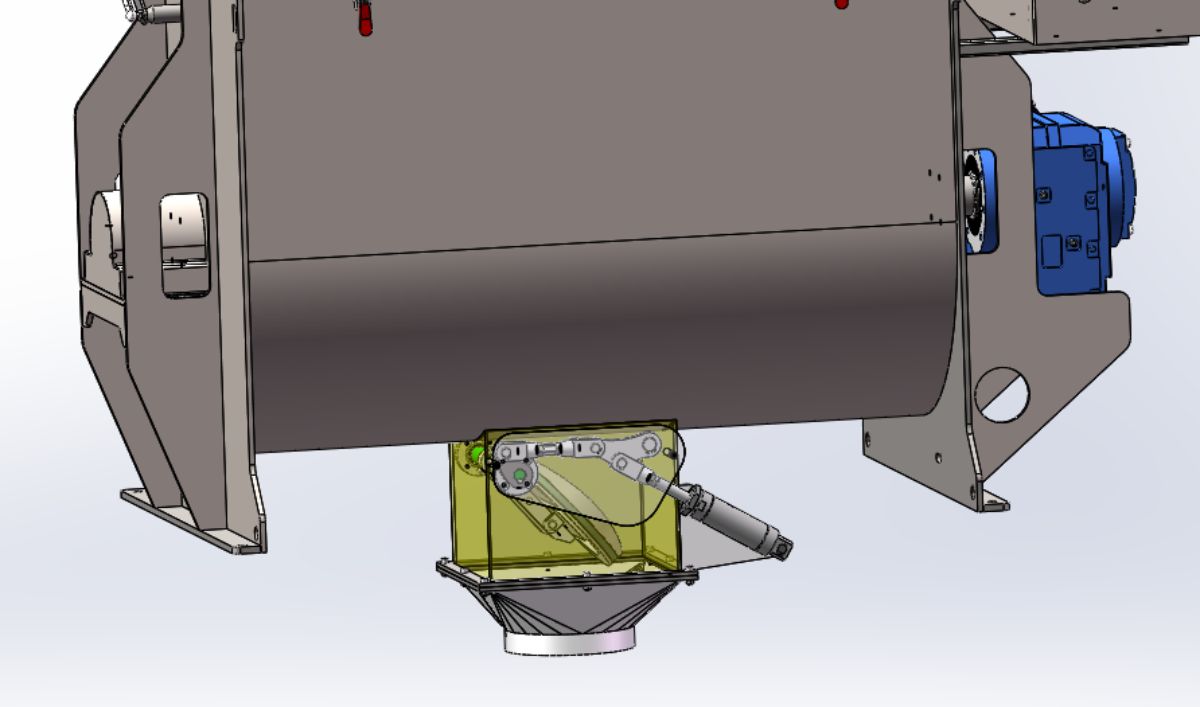

A patented technology discharge, flap dome valve with either manual or pneumatic control is located under the tank's bottom. The arc-shaped valve ensures that no material builds up and that there is no dead angle during mixing. Dependable reg seal prevents leaks between frequent openings and closings.

The mixer's double ribbon allows for faster and more uniform mixing of the material in a short amount of time.

The entire machine is made of stainless steel 304 material, with the inside of the mixing tank, ribbon, and shaft all fully mirror polished.

Equipped with a safety switch, safety grid, and wheels to ensure safe and easy operation.

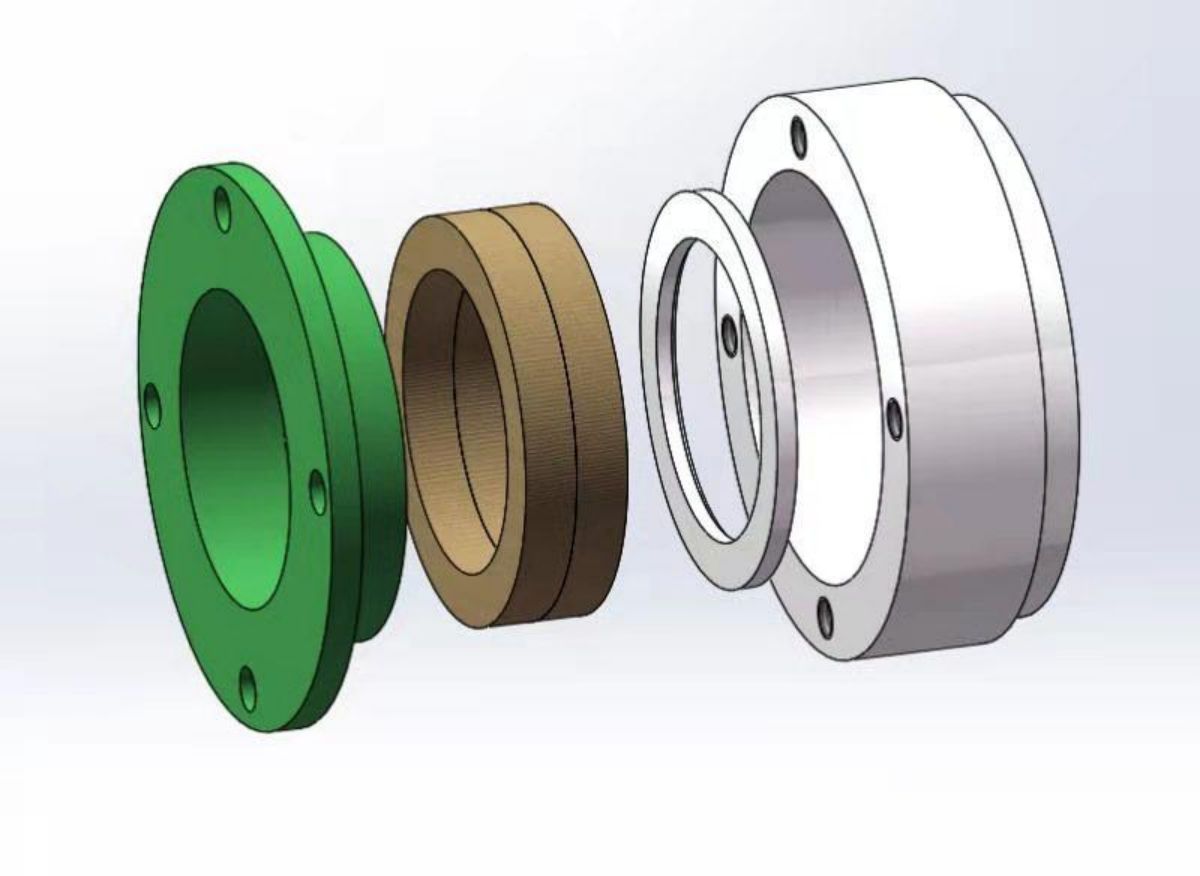

Completely leak-proof shaft sealing made of Teflon rope with a special design and the German brand Bergman.

System of loading:

For smaller models of mixers, there are stairs; for bigger models, there is a working platform with steps; and there is a screw feeder for automated loading.

It can link with other machines like with screw feeder, auger filler and more.

Post time: Dec-27-2023