In today's blog, let's tackle how effective and quality the China ribbon mixer is.

Effectiveness of China ribbon mixer:

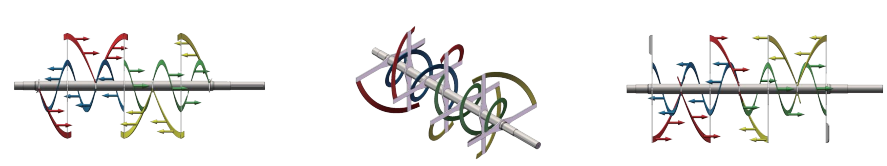

A China ribbon mixer works well for mixing various powders, such as powder with liquid spray, powder with granules, etc. The twin ribbon agitator's unique shape allows the material to quickly achieve a high level of effective convective mixing.

The mixer's twin ribbon can quickly and uniformly mix the material at a higher speed in a short time.

While the machine is operating, the product is pushed from the sides for convective mixing by the inner ribbon, which moves the material from the sides to the middle of the tank.

Quality of China ribbon mixer:

The whole unit is made of stainless steel 304, with the ribbon and shaft as well as the inside of the mixing tank fully mirror polished. It is a combined food-grade standard shaft and tank. The tank is devoid of any nuts.

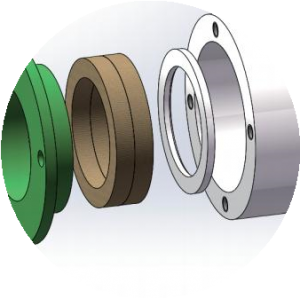

It uses patented shaft sealing and discharge technology. A water test to ensure there are no leaks.

With Teflon rope (Bergman brand, Germany) and a distinctive design, there is never a leak in the shaft sealing.

There is a flap dome valve (manual or pneumatic control) located beneath the tank's bottom. The arc-shaped valve ensures that no material builds up and that there is no dead angle during mixing. Dependable, regular sealing prevents leaks between frequent openings and closings.

Ribbon: 8–14 mm thick. the high strength of mixing.

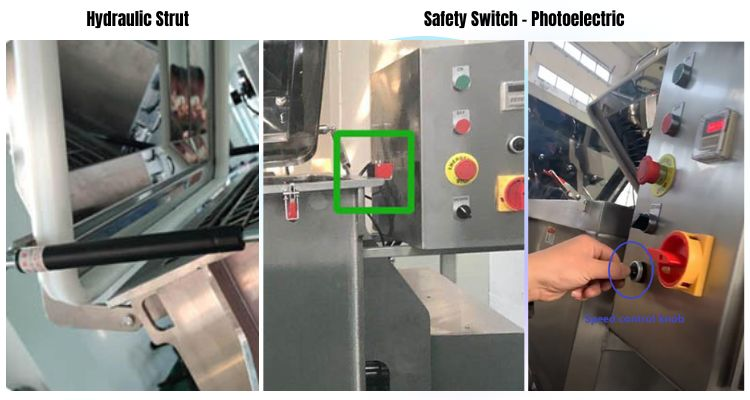

Equipped with a safety switch, safety grid, and wheels to ensure safe and easy operation.

With full certificates and patent:

Fill Volumes:

The TDPM series ribbon mixer family of machines functions by filling volume instead of the mixing tank's maximum weight capacity. This is due to the fact that a powder mix's bulk density may affect how much it weighs.

Only a fraction of the whole tank volume is represented by the maximum fill volume of the mixing tank in the TDPM series ribbon mixer. The bulk density of the powder product being utilized is the basis for determining this maximum fill volume.

Post time: May-28-2024