The liquid mixing machine is fully welded and has a custom design made to fit your requirements. SS304 or SS316 are the available materials. Testing is done before production, including temperature and pressure, and it is designed with double or triple walls.

Here the instructions how to keep and maintain the liquid mixing machine effectively:

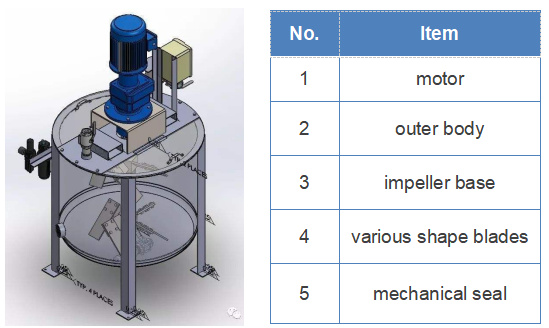

1. The maintenance staff who are familiar with the structure and functionality of the stirring system are necessary to operate this kind of efficient operation. The mixer can be safely operated over the long term with proper inspection and maintenance.

2. Before starting, the high-efficiency mixing system needs to have its gearbox, intermediate bearings, and motor bearings greased.

Add 2 # calcium lithium grease to the machine bearings and intermediate bearings; add 30 # mechanical oil to the gearbox; and fill the oil cup to the top in the middle of the machine.

3. Every six months, the motor bearings and intermediate bearings must be replaced. About the engine oil, you can always add oil to the oil cup if you notice that there is a lack of it. The six-month cycle must follow; After six months of use, the transmission must be filled with oil.

Once it’s done, you must pour out the lubricant and reapply it.

4. This method refers to the lubrication in the gearbox and needs to be emptied out each year, the gearbox needs to be cleaned with a cleaning agent and lastly rinse once when all done. In addition, look for a significant wear and corrosion on the gears inside the gearbox.

5. This method pertains to the maintenance staff must periodically inspect the operation. whether each bearing is vibrating, overheating, or producing noise.

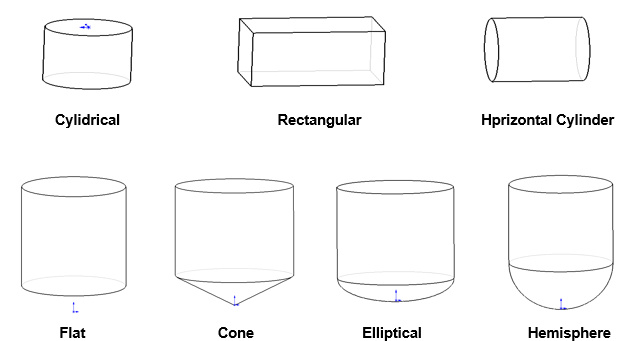

The bottom's form and the tanks' geometry:

Hemisphere

Cone

Elliptical

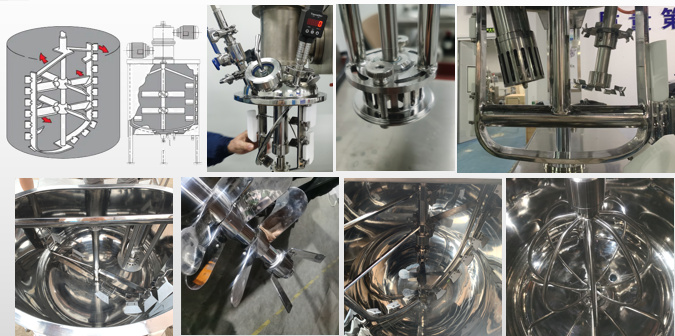

Various forms of agitators:

Post time: May-09-2024