A.Manual loading

Open the cover of the blender and manually load materials directly, or make a hole on the cover and add materials manually.

B.By screw conveyor

The screw feeder can convey powder and granule material from one machine to another. It's efficient and convenient. It can work in cooperation with the packing machines to form a production line. So it is widely used in packaging line, especially semi-auto and automatic packaging line. It is mainly used in conveying powder materials, such as the milk powder, protein powder, rice powder, milk tea powder, solid beverage, coffee powder, sugar, glucose powder, food additives, feed, pharmaceutical raw materials, pesticide, dye, flavour, fragrances and so on.

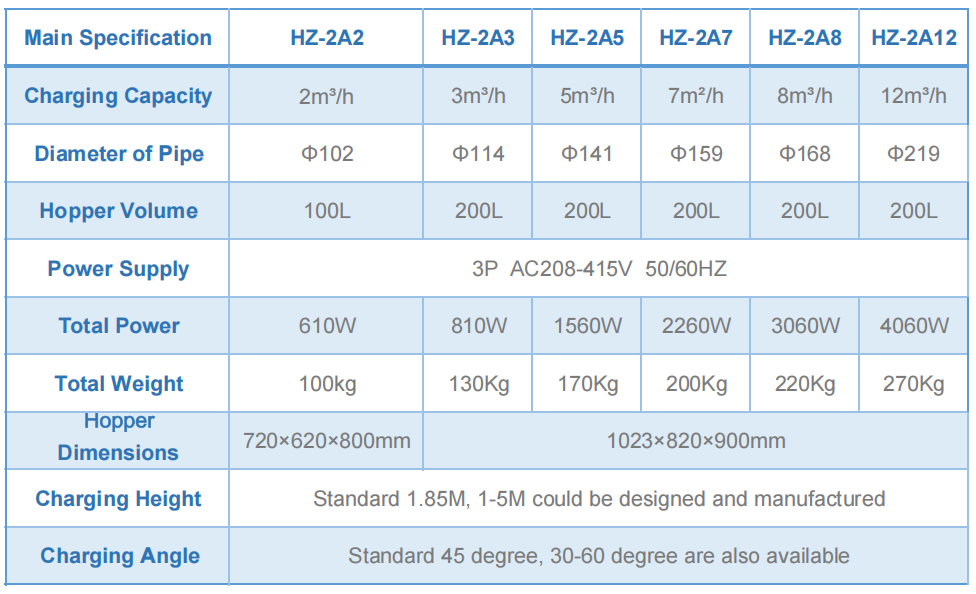

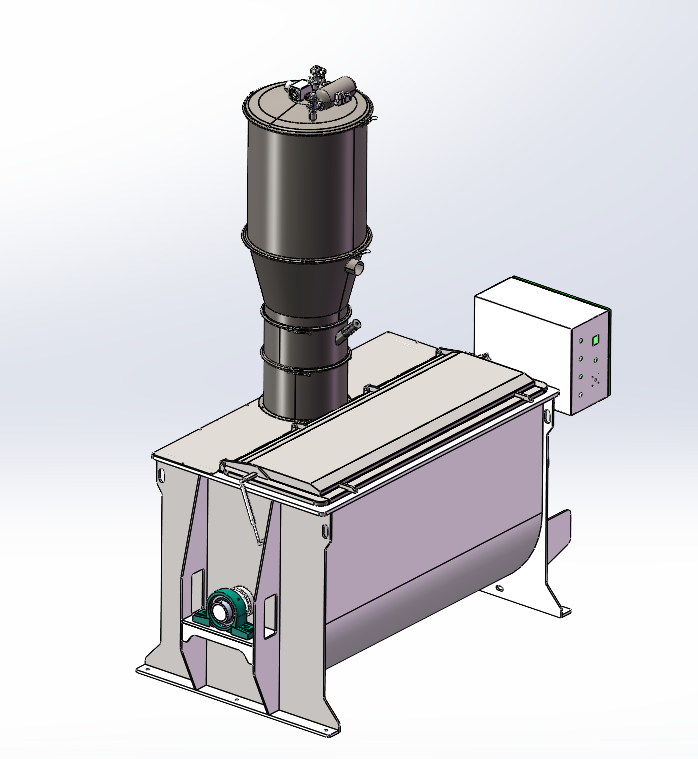

Screw conveyor is composed of Feeding motor, vibrator motor, hopper, tube, and screw. Standard model with 45 degree charging angle and 1.85 m charging height. The capacity have 2m3/h、3 m3/h、5 m3/h、8 m3/h etc speed. Others can be customized.

Working principle:

The screw feeder moves the product upward through a completely closed helical rotating shaft. The speed of the screw body is higher than that of the ordinary screw conveyor. Under the action of centrifugal force, the conveyed material and the casing produce friction, which prevents the material from rotating with the screw blade and overcomes the problem of the material. Falling gravity, thus realizing the inclined or vertical conveying of materials.

C.By vacuum conveyor

Vacuum feeder unit is using whirlpool air pump extracting air. The inlet of absorption material tap and whole system is made to be in vacuum state. The powder grains of material are absorbed into the material tap with ambient air and formed to be the air flowing with material. Passing the absorption material tube, they arrive to the hopper. The air and materials are separated in it. The separated materials are sent to the receiving material device. The control center controls the “on/off” state of pneumatic triple valve for feeding or discharging the materials.

In the vacuum feeder unit the compressed air opposite blowing device is fitted. When discharging the materials every time, the compressed air pulse oppositely blows the filter. The powder attached on the surface of filter is blown off for ensuring normal absorbing material.

The pneumatic vacuum feeder high vacuum through the vacuum generator using compressed air to achieve the delivery of materials, no mechanical vacuum pump, has a simple structure, small size, maintenance-free, low noise, easy to control, eliminate material static and in accordance with GMP requirements, etc.. The high vacuum of the vacuum generator, and the transportation of materials to prevent stratification and to ensure the homogeneity of the mixed material composition is blender automatic feeding device of choice.

Comparison of screw conveyor and screw feeder

The advantages of vacuum feeder mainly include:

1)Dust-free closed pipeline transportation can effectively reduce dust pollution and improve the working environment. It also reduces the pollution of the environment and personnel to materials and improves cleanliness.

2)Occupies little space, can complete powder transportation in small spaces, making the workspace beautiful and generous.

3)Not limited by long or short distance, especially suitable for long-distance transportation.

4)Reduce manual labor intensity and improve work efficiency. It is the first choice for most powder material transportation methods.

Disadvantages include:

1)Not suitable for conveying materials that are too wet, sticky, or too heavy.

2)The requirements for the outer dimensions and density of materials are relatively strict. For materials with different shapes or densities, the conveying quality may be greatly compromised.

The advantages of screw feeders include:

1)The requirements for the outer dimensions and density of materials are relatively loose. As long as the materials can enter the spiral smoothly, they can be transported to high places basically without distinction.

2)It is less difficult to clean when changing material types, and it is simpler than the vacuum feeder.

The main disadvantages are:

1)Not suitable for long-distance transportation, because its transportation efficiency will decrease as the distance increases.

2)Powder or flying materials may cause dust pollution.

So vacuum feeders and screw feeders each have their own applicable scenarios and limitations. Which feeder to choose should be comprehensively considered based on factors such as specific material characteristics, production environment, and production efficiency requirements.

If you have any further questions regarding the principle of the ribbon blender, feel free to contact us for consultation. Leave your contact information, and we will get in touch with you within 24 hours to assist and clarify any doubts you may have.

Post time: Mar-06-2025