Did you know that a machine needs to be maintained so that it will be in good condition and avoid rust?

In this blog I will discuss and give you steps to maintain the machine in good condition.

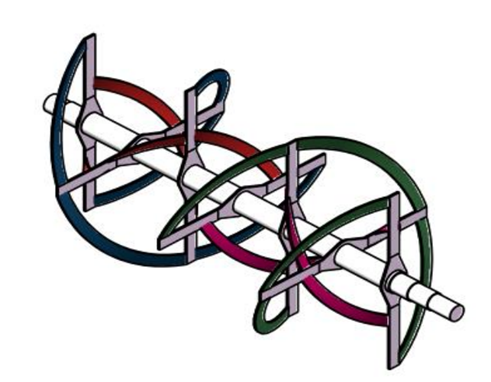

First I will introduce what a ribbon blender machine is.

The ribbon blender machine is a horizontal mixer with a U-shaped design. It is effective for mixing different types of powders, powder with liquid, powder with granules, and dry solids. The chemical industry, food industry, pharmaceutical industry, agricultural industry, and many more use ribbon blender machines. The ribbon blender machine is a multifunctional mixing machine with a steady operation, consistent quality, low noise, long life, simple installation and maintenance. Another type of ribbon blender machine is the double ribbon mixer.

Main Features:

● Inside the tank of ribbon blender machine is a complete mirror polished as well as ribbon and shaft.

● All parts of ribbon blender machine are fully welded.

● Ribbon blender machine is made up of stainless steel 304 material and can also be made of 316 and 316 L stainless steel.

● Ribbon blender machine has a safety switch, grid and wheels for safety using.

● Ribbon blender machine has patent technology on shaft sealing and discharge design.

● The ribbon blender machine can be adjusted into high speed for mixing the materials within a short time.

The structure of a ribbon blender machine

The ribbon mixer is made up of the following parts:

1. Cover/Lid

2. Electric Control Box

3. Tank

4. Motor & Reducer

5. Discharge Valve

6. Frame

7. Caster/Wheels

Working Principle

Ribbon blender machine is made up of transmission parts, twin ribbon agitators, and a U-shaped chamber. A ribbon mixer agitator is made up of an inner and outer helical agitator. The outer ribbon moves materials one way, while the inner ribbon moves materials the other way. The ribbons rotate approximately to move the materials both radially and laterally to ensure the blends in short cycle times. The material being used in making ribbon blender machine is stainless steel 304.

How to maintain a ribbon blender machine?

-The thermal protection relay's current should be matched to the motor's rated current; otherwise, the motor may be damaged.

- If any unusual noises, such as metal cracking or friction, occur during the mixing process, please stop the machine immediately to check and fix the problem before restarting.

The lubricating oil (model CKC 150) should be replaced periodically. (Remove the black rubber)

- Keep the machine clean on a regular basis to prevent rust.

- Please use a plastic sheet to cover the motor, reducer, and control box and wash them with water.

- Air blowing is used to dry the water droplets.

- Changing the packing gland from time to time. (If necessary, a video will be sent to your email)

Always remember to keep your ribbon blender machine well maintained.

Post time: Feb-07-2022