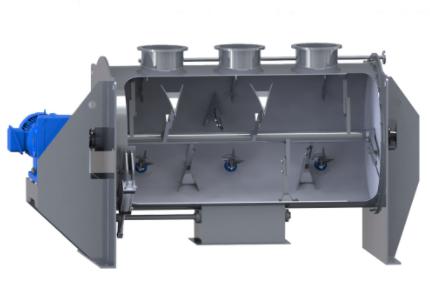

Horizontal double ribbon blender applies in mixing powder with powder, granule, past or little liquid, which is widely used in food, pharmaceutical, chemical, agriculture industry etc.

Are you confused to choose a ribbon blender? Hope this article helps you on making decision.

There are three steps to choose a suitable mixer.

1. Select suitable stirrer.

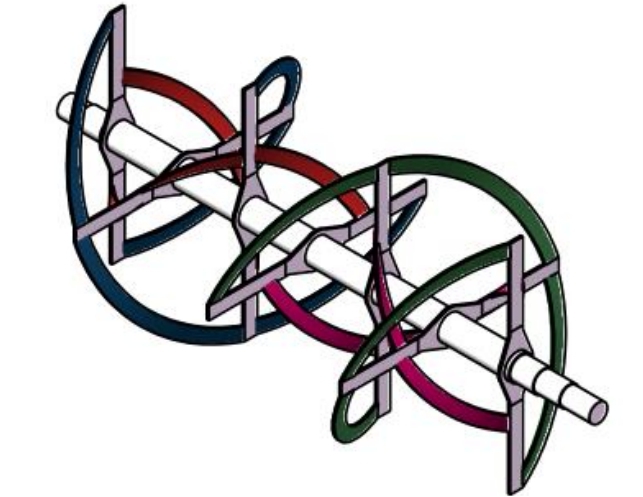

To be options of stirrer inside, ribbon, paddle, colter are common.

Ribbon suits mixing powder with similar densities, and powder easy to get caking.

Because ribbon moves materials in opposite directions to achieve convection and crush clumps.

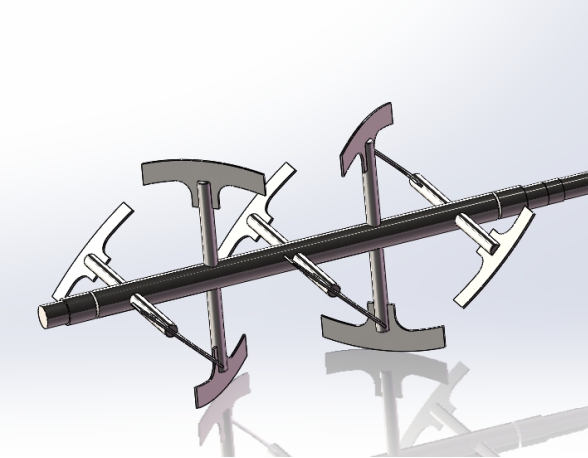

Paddle is suitable to mix powder

granule or paste have big difference in densities.

Because paddles throw material from bottom to top, which can keep origin shape of ingredients and prevent larger density material staying at bank bottom.

Ribbon and paddle can be combined, which suits various ingredients. If you have many product with both powder and granule, this stirrer will be your best choice.

Colter plus cutter, double action will achieve high homogeneity in very short time. It is more suitable for powder with raw material like paste and fiber.

2. Choose a suitable model

Once choosing the ribbon blender, it comes to the part to select a suitable volume model. Normally effective mixing volume takes 70% of total volume. And some suppliers name their models with total mixing volume, while some like us name our ribbon blender models with effective mixing volume.

However, you might arrange your output with weight not volume. You will need to calculate the output volume each batch according to your product density.

For example, a manufacturer produces 500kg flour each batch, with four density 0.5kg/L. The output will be 1000L each batch. What they need is a 1000L capacity ribbon blender. So our TDPM 1000 model is suitable.

Please pay attention to the model of suppliers. Make sure 1000L is their capacity not total volume.

3. Check ribbon blender quality

The last step is to choose a ribbon blender with high quality. There are some problems most likely to occur on a not so good ribbon blender.

Shaft sealing: the good shaft sealing can pass the water test. Powder leak from shaft sealing always troubles users.

Discharge sealing: test with water also shows the discharge sealing effect. Many users have met leakage trouble at discharge.

Full-welding: Full welding is one of the most important part for food and pharmaceutical machines. With non-full welding, powder will stay in gap, which might pollute fresh powder in next batch. But full-welding and good polish get rid of each gap between hardware connection, which will bring you good machine quality and usage experience.

Easy-cleaning design: A easy-cleaning ribbon blender will save you much time and energy.

Hope you will get some good idea from this article, and hope you will get a satisfied ribbon blender.

Post time: Jan-26-2022