Components:

1. Mixer Tank

2. Mixer Lid/Cover

3. Electric Control Box

4. Motor and Gear Box

5. Discharge Valve

6. Caster

The Ribbon mixer machine is a solution to blend powders, powder with liquid, powder with granules, and even the smallest quantity of components. Commonly used for food, pharmaceuticals as well as construction line, agricultural chemicals and etc.

Main features of ribbon mixer machine:

-All connected parts are well-welded.

-What’s Inside the tank is full mirror polished with ribbon and shaft.

-All material is stainless steel 304 and can also be made of 316 and 316 L stainless steel.

-It has no dead angles when mixing.

- With safety switch, grid and wheels for safety using.

- The ribbon mixer can be adjusted into high speed for mixing the materials within a short time.

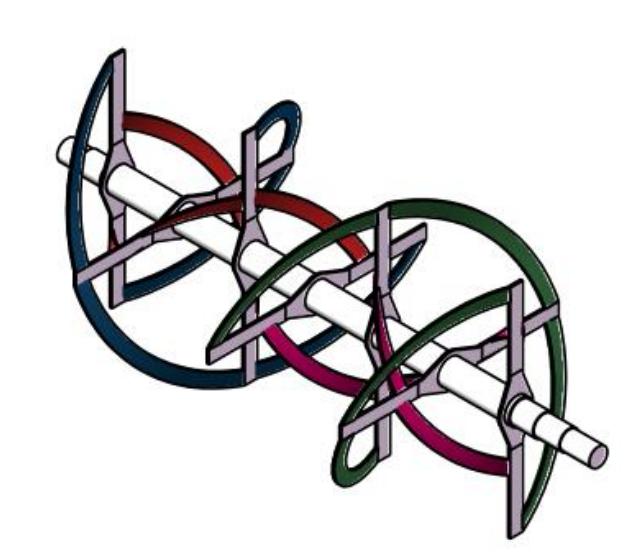

Ribbon mixer machine structure:

Ribbon mixer machine has ribbon agitator and a U-shaped chamber for highly- balanced mixing of materials. The ribbon agitator is made up of inner and outer helical agitator.

The inner ribbon moves the material from center to outside while outer ribbon moves the material from two sides to the center and it is combined with rotating direction when moving the materials. Ribbon mixer machine gives a short time on mixing while providing a better mixing effect.

Working Principle:

When using a ribbon mixer machine, there are steps to follow to produce mixing effects of materials.

Here are the set up process of ribbon mixer machine:

Before being shipped, all of the items were thoroughly tested and inspected. However, in the process of transportation, the components may get loose and wear out. When the machines arrive, please inspect the outer packaging and the machine's surface to ensure that all parts are in place and that the machine can function normally.

1. Fixing footed glass or casters. The machine should be placed on a level surface.

2. Confirm that the power and air supply are in line with the needs.

Note: Make sure the machine is well-grounded. The electric cabinet has a ground wire, but because the casters are insulated, only one ground wire is required to connect the caster to the ground.

3. Cleaning the mixing tank completely before to operation.

4. Switching the power on.

5.  Putting the main power switch on.

Putting the main power switch on.

6.  To open the power supply, rotate the emergency stop switch clockwise.

To open the power supply, rotate the emergency stop switch clockwise.

7.  Checking whether the ribbon rotates by pressing the "ON" button

Checking whether the ribbon rotates by pressing the "ON" button

The direction is correct everything is normal

9. Connecting air tube to 1 position

In general, 0.6 pressure is good, but if you need to adjust the air pressure, pull the 2 position up to turn right or left.

Here are the operation steps of ribbon mixer machine:

1. Switch the power on

2.  Switching the ON direction of the main power switch.

Switching the ON direction of the main power switch.

3.  To turn on the power supply, rotate the emergency stop switch in a clockwise direction.

To turn on the power supply, rotate the emergency stop switch in a clockwise direction.

4.  Timer setting for the mixing process. (This is the mixing time, H: hours, M: minutes, S: seconds)

Timer setting for the mixing process. (This is the mixing time, H: hours, M: minutes, S: seconds)

5.  The mixing will begin when the "ON" button is pressed, and it will end automatically when the timer is reached.

The mixing will begin when the "ON" button is pressed, and it will end automatically when the timer is reached.

6. Pressing the discharge switch in the "on" position. (The mixing motor can be started during this procedure to make it easier to discharge the materials out of the bottom.)

Pressing the discharge switch in the "on" position. (The mixing motor can be started during this procedure to make it easier to discharge the materials out of the bottom.)

7. When the mixing is finished, turn off the discharge switch to close the pneumatic valve.

8. We recommend feeding batch by batch after the mixer has started for products with a high density (greater than 0.8g/cm3). If it begins after a full load, it may cause the motor to burn down.

Guidelines for safety and caution:

1. Before mixing, please make sure the discharge valve is closed.

2. Please keep the lid closed to keep the product from spilling out during the mixing process, which could result in damage or an accident.

3.  The main shaft should not be turned in the opposite direction to the prescribed direction.

The main shaft should not be turned in the opposite direction to the prescribed direction.

4. In order to avoid motor damage, the thermal protection relay current should be matched to the motor's rated current.

5. When certain unusual noises, such as metal cracking or friction, happen during the mixing process, please stop the machine right away to look into the issue and solve it before restarting.

6. The time it takes to mix can be adjusted from 1 to 15 minutes. Customers have the option of selecting their desired mixing time on their own.

7. Change the lubricating oil (model: CKC 150) on a regular basis. (Please remove the black-colored rubber.)

8. Regularly clean the machine.

a.) Wash the motor, reducer, and control box with water and cover them with a plastic sheet.

b.) Drying the water droplets by air blowing.

9. Replacing the packing gland on a daily basis (If you need a video, it will be forwarded to your email address.)

I am hoping this may provide you some insight into how to use the ribbon mixer.

Post time: Jan-26-2022