Did you know that regular maintenance keeps a machine in excellent working order and prevents rust?

I'll go over how to keep the machine in excellent working order in this blog and provide you with some instructions.

I'll start by defining a powder mixing machine.

The powder mixing machine is a U-shaped horizontal mixer. It works well for combining various powders, dry solids, powder with granules, and powder with liquid. Powder mixing machines are used by the chemical, food, pharmaceutical, agricultural, and many other industries. It is a multipurpose mixing device that is easy to install and maintain, has a long lifespan, minimal noise, stable operation, and consistent quality.

Characteristics

• Each part of the machine is entirely welded, and the inside of the tank is completely mirror polished, along with the ribbon and shaft.

• Composed of 304 stainless steel, while it is also available to use 316 and 316 L stainless steel.

• It has wheels, a grid, and a safety switch for user safety.

• Full patent technology on shaft sealing and discharge design

• It is capable of being set at a high speed to quickly mix the ingredients.

The structure of a powder mixing machine

1.Cover/Lid

2.Electric Control Box

3.U-Shaped Tank

4.Motor & Reducer

5.Discharge Valve

6.Frame

7.Caster

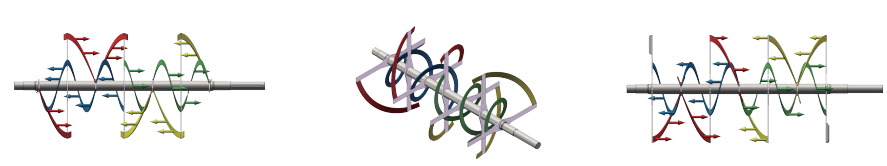

Operational idea

An inner and an outer helical agitator comprise a ribbon mixer agitator. Materials are moved in one direction by the outer ribbon and in the other direction by the inner ribbon. To guarantee that the blends occur in brief cycle periods, the ribbons rotate rapidly to move the materials both laterally and radially.

How should a powder mixing machine be maintained?

-The motor may sustain damage if the thermal protection relay's current is not equal to the motor's rated current.

- Please stop the machine right once to inspect and address any strange noises, such as metal breaking or friction, that may occur during the mixing process before restarting.

The lubricating oil (model CKC 150) should be replaced periodically. (Remove the black rubber)

- To avoid corrosion, keep the machine clean often.

- Please cover the motor, reducer, and control box with a plastic sheet and give them a water wash.

- The water droplets are dried by air blowing.

- Altering the packing gland periodically. (If required, your email will get a video.)

Never forget to maintain the cleanliness of your powder mixing machine.

Post time: Jul-08-2024