Definitely YES, an Auger Filling Machine Factory.

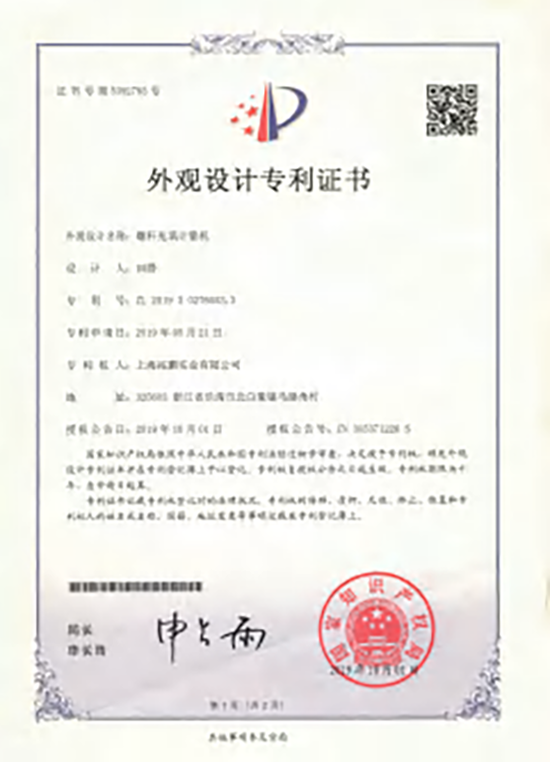

Shanghai Tops Group is an auger filling machine factory. Furthermore, with modern auger powder filler technology, Tops Group have an established capacity for production. Our patent pertains to servo auger filler appearance.

Moreover, auger filling machine factory can provide regular layouts in a matter of 7 days on average.

Additionally, TOPS GROUP is able to customize the auger filler to meet your specifications. Based on your design drawing, we can manufacture the auger filler with your logo or business details on the machine label. We are also able to provide auger filling components. We are also able to use the particular brand if you have an object configuration.

Important Servo Auger Filler Technology:

Servo motor: To achieve high filling weight precision, we used a Taiwan-made Delta servo motor to regulate the auger. One can designate the brand.

A servomotor is a linear or rotary actuator that enables accurate control over acceleration, velocity, and angular position. It is made up of an appropriate motor connected to a position feedback sensor. It also needs a rather complex controller, which is frequently a specialized module made just for servomotor applications.

Central components: The area of greatest importance for auger filler is the central component of the auger.

TOPS GROUP auger filling machine factory does well in assembly, precision processing, and central components. Although processing precision and assembly are invisible to the unaided eye and cannot be intuitively compared, it will become evident in use.

High concentricity: If the auger and shaft don't have a high degree of concentricity, the accuracy won't be excellent.

Between the servo motor and auger, we use a shaft from a globally renowned brand.

Precision machining: To create a small-sized auger with consistent dimensions and an extremely precise form, we use a milling machine.

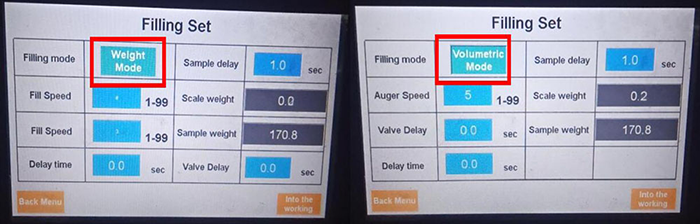

Two filling modes: volume and weight modes are interchangeable.

Mode of volume:

The powder volume reduced by one cycle of screw rotation is constant. The number of revolutions the screw has to make to obtain the desired filling weight will be determined by the controller.

Mode of weight:

A load cell beneath the filling plate measures the filling weight in real time. To achieve 80% of the goal filling weight, the first filling is quick and heavy.

The second filling, which supplements the remaining 20% based on timely filling weight, is precise and gradual.

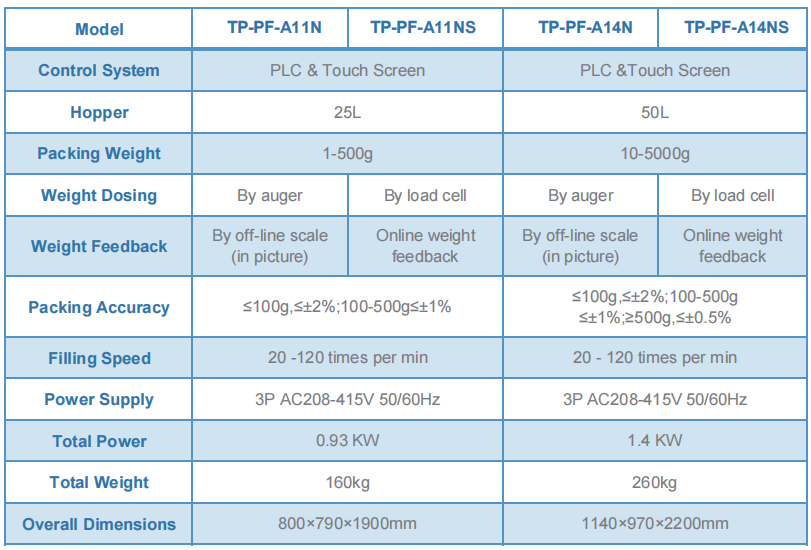

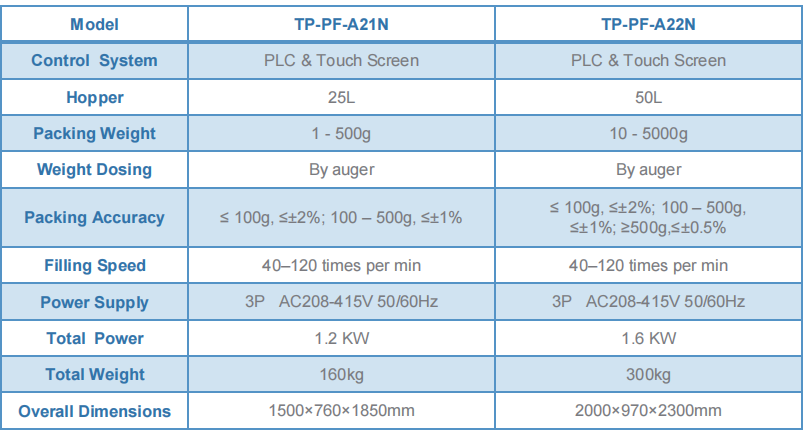

Various Auger Filling Machine Factory Types:

Auger fillers that are semi-automated and automatically operated.

Both dosing and filling activities can be performed by this kind of equipment. It's appropriate for products with different fluidity levels, including coffee powder, pharmaceuticals, pesticides used in agriculture, and more, through its specialized professional design.

SEMI- AUTOMATIC

AUTOMATIC

Post time: Dec-20-2023