-

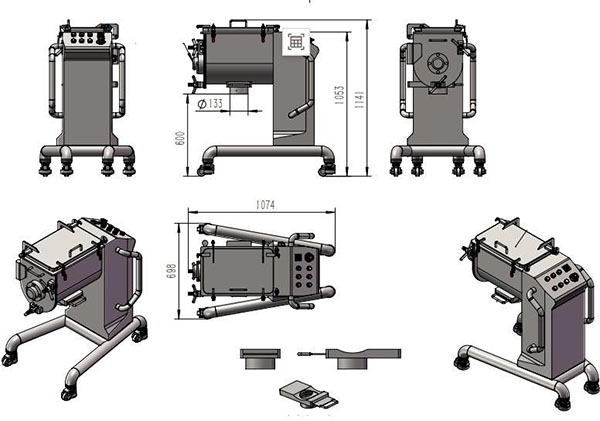

The Guidelines and Ways to consider for Mini-type Ribbon Mixers Performance

Mini-type ribbon mixer performance is heavily influenced by design and setup. Here are some guidelines and considerations for optimizing the design and configuration of such mixers: Mixer Size and Capacity: Based on intended application, determines the suitable mixer size and capacity. Mini-t...Read more -

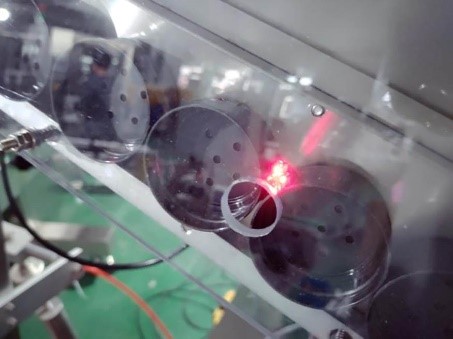

Automatic Packaging Devices also called Vertical Form Fill Seal (VFFS)

Automatic packaging devices are known for Vertical Form Fill Seal (VFFS) are packing machines used to form, fill, and seal flexible bags or pouches in a vertical configuration. They are extensively utilized in various industries for quicker and more effective packaging ...Read more -

The advantages in using a Powder-Cake Crusher Machine

The following are some of the advantages of using a powder cake crusher machine (also known as a powder-cake grinder): Powder-cake crusher machines are specifically intended to crush compacted or caked powder materials into tiny particles. They use a strong-crushing mechanisms that effectively re...Read more -

A Paddle Mixer: For Delicate Mixing and Blending of Materials

For delicate mixing and blending of materials, paddle mixers are frequently employed in a variety of industries. A paddle mixer's efficiency is influenced by a number of process variables that can be changed to improved more in mixing results. The following are some cru...Read more -

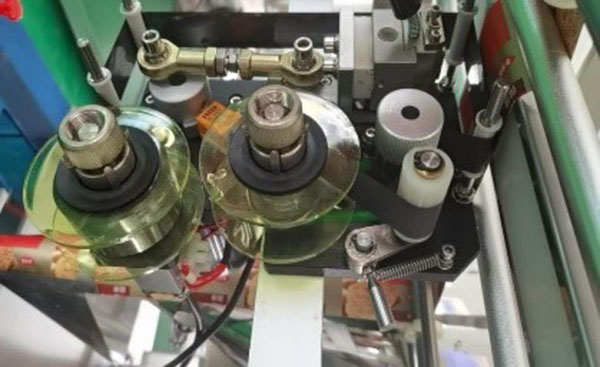

Why Capping Machines are crucial for safety capping or closing containers?

In the packaging industry, capping machines are crucial for safety capping or closing containers. A capping machine’s design incorporates a number of parts and systems to guarantee an accurate and dependable cap application. These are the following crucial elements of capping machine design...Read more -

The Specialized Applications of a Ribbon Mixer

“Ribbon Mixers” have a specialized applications in a variation of industries, where accurate and efficient mixing is critical. Here are some specific illustrations of specialized Ribbon Mixer applications: Food industry: This machine is intended to mix dry ingredients such as flour, sugar, spic...Read more -

The Difference Between the Dual-Head Auger Filler and Four-Head Auger Filler.

The primary distinction between a “Dual-Head Auger Filler and a Four-Head Auger Filler” are the number of auger filling heads. The following are the key distinctions: Auger Filler with Dual Heads: The number of filling heads on a ...Read more -

Proper Steps for Efficient and More Effective Ways Using a Ribbon Mixer.

Using a Ribbon Mixer involves a series of steps to ensure efficient and effective material for blending. Here’s an overview on how to use a Ribbon Mixer: 1. Preparation: Learn how to custom the ribbon mixer’s controls, settings, and safety features. Ascertain that you have read and ...Read more -

The Difference Between a double cone mixer and a V mixer

The primary distinctions between a "Double Cone Mixer and a V Mixer” is found in their geometries and mixing principles. Here’s the following key factors on their differences: Double Cone Mixer: A “Double Cone Mixer” is made up of two conical-shaped vessels that joins t...Read more -

Simple Maintenance and Cleaning for a Double Cone Mixer

Maintaining and cleaning are simplest task to a “Double-Cone Mixer”. It is essential ways to maintain and cleaning the double-cone mixer to guarantee its effective operation and to prevents cross-contamination between diverse batch...Read more -

Intelligent Capping Machine Automation

“Intelligent Capping Machine Automation” entails to integrates advanced technologies and systems to streamline the capping process, improve efficiency, and improved overall performance. Here are some of the most important aspects o...Read more -

“Efficient and Consistent Mixing with Stainless Steel Spiral Ribbon Mixers for the Food Industry”

The spiral ribbon mixer is a type of mixing equipment commonly used in the food industry for blending various types of food powders. Its structure is made of stainless-steel...Read more