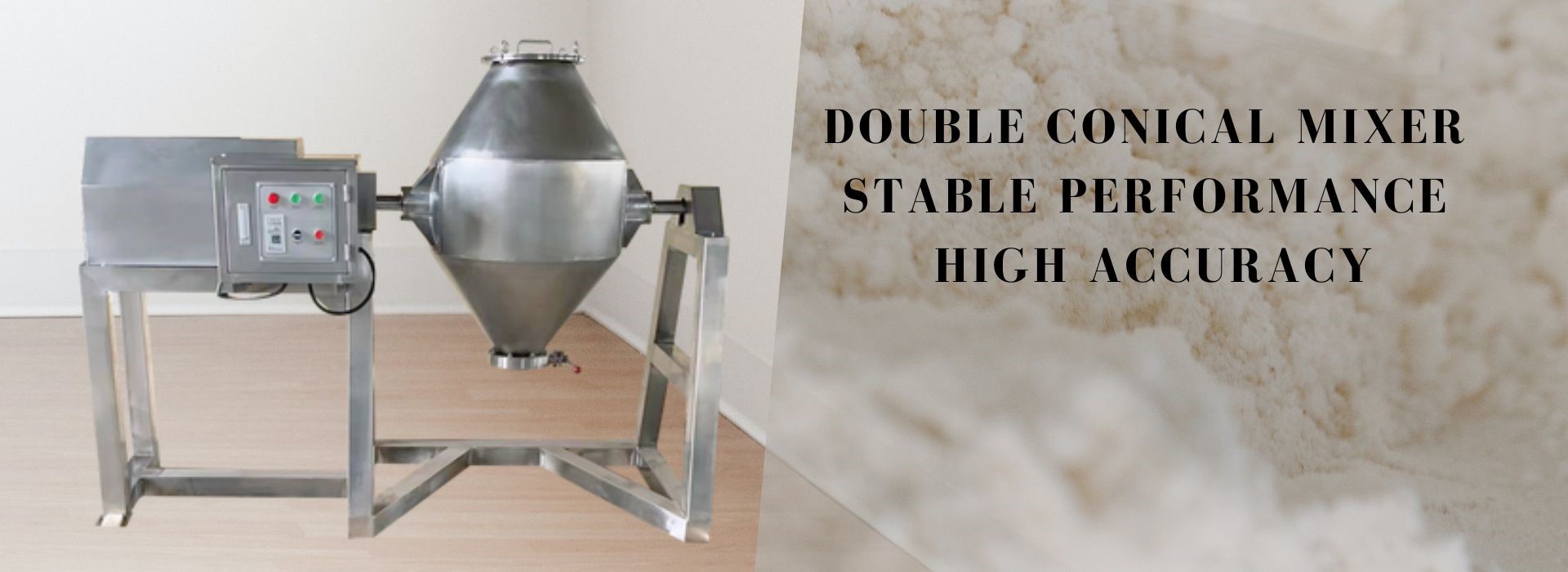

Maintaining and cleaning are simplest task to a “Double-Cone Mixer”. It is essential ways to maintain and cleaning the double-cone mixer to guarantee its effective operation and to prevents cross-contamination between diverse batches of materials. Here are some simple cleaning and maintenance tips for a “Double-Cone Mixer”:

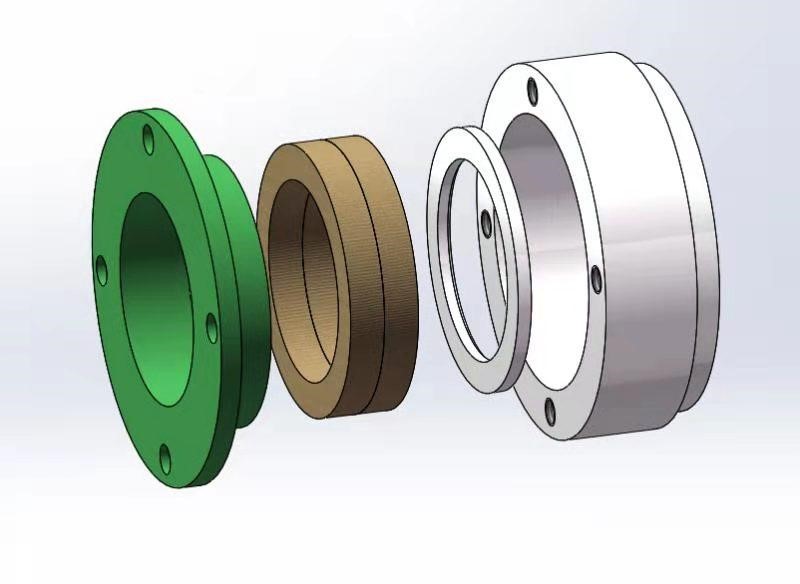

Regular Inspection: Inspect the double cone mixer regularly for any signs of wear, damages, or misalignment. Examined the condition of the sealing components, such as gaskets or O-rings, to ensure that they are intact and functional.

Lubrication: Follow the manufacturer's recommendations on lubricating the moving parts of the double-cone mixer, such as bearings or gears. This reduces, prevents premature wear, and guarantees smooth operation.

Cleaning Before and After Use:

Systematically clean the double-cone mixer before and after each use.

Take up the following steps:

a. Remove any remaining materials from the mixer by rotating it and discharging the contents.

b. For easier cleaning, remove any easily detachable parts, such as the cones or lids.

c. To clean the interior surface, including the cones, blades, and discharge port, use the cleaning agents or solvents recommended by the manufacturer.

d. To remove any residual material, gently scrub the surfaces with a soft brush or sponge.

e. To remove any cleaning agents or residues, thoroughly rinse the mixer with clean water.

f. Before reassembling and storing the mixer, let it dry completely.

Prevent Cross-Contamination:

To avoid cross-contamination between diverse materials, thoroughly clean the double cone mixer and remove any residue or trace of a materials before introducing a new batch. This is especially important when working with allergens or materials that have strict quality control requirements.

Excessive Pressure:

Avoid using excessive pressure when cleaning or assembling the double cone mixer, as it may damage the delicate parts. To avoid unnecessary force or stress on the equipment, follow the manufacturer's instructions and guidelines.

After cleaning, make sure that the double cone mixer is completely dry before storing it. Keep the mixer clean and dry, away from moisture, dust, and the other contaminants. Proper storage helps keep the mixer clean and extends its lifespan.

Operator Education:

Educate the operators on the proper maintenance and cleaning procedures for the double-cone mixer. Educate them on the importance of the following cleaning protocols and the manufacturer's maintenance and care guidelines.

For detailed maintenance and cleaning procedures, refer to the specific maintenance instructions provided by the manufacturer of your double-cone mixer. Following these guidelines will help ensure the longevity and peak performance of the double cone mixer.

Post time: May-24-2023