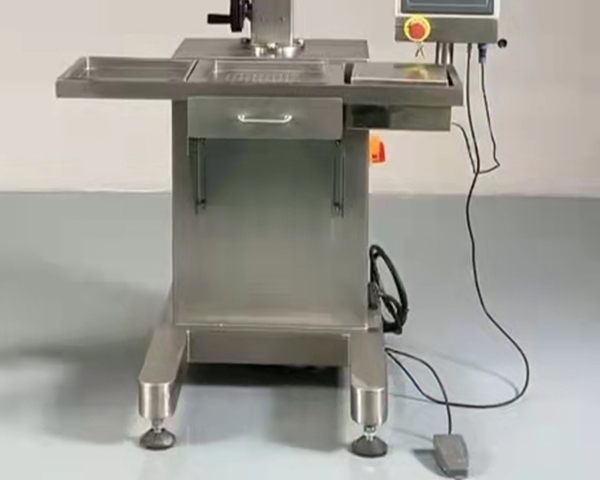

This technique can put a great deal of powder into bottles and bags. Due to its unique professional design, it is suitable for fluidic or low-fluidity materials together with talcum powder, coffee powder, wheat flour, condiments, solid drinks, veterinary medications, dextrose and medicines.

Functionality:

Lathing the auger screw to ensure accurate filling.

Touchscreen display with PLC control.

A servo motor operates the screw to provide steady functioning.

The quick-detachable hopper was simple to clean without the use of any tools.

A pedal switch allows either semi-auto or automatic filling.

304 stainless steel is used exclusively.

Weight feedback and proportional tracking of the materials help overcome the challenges of filling weight fluctuations brought on by changes in the density of the materials.

20 sets of formulas can be saved inside the device for further use.

Variable materials, ranging from fine powder to granules with variable weight, can be packed by changing the auger sections.

These are the Multilingual User Interface:

1. Type shift

This type of shift is more flexible in switching between automatic and semi-automated types on the same equipment.

Automatic Type

Semi-Automated Type

2. Split-level hopper

Flexible in change type; very simple to open and cleaning the hopper.

3. Auger Screw and Tube

One size screw is ideal for one weight range, such as dia, to ensure filling precision. Through this 38-mm screw can hold up to 100g to 250g of materials.

Always remember to follow the steps given on the user-guide manual. Familiarize all the spare parts and their functions. Always check the machine when using, avoid using it and leaving it to avoid unexpected malfunction that can lead to accidents. If there’s an unexpected machine breakdowns just contact our technicians right ahead to address the problems.

Post time: Sep-12-2023