This type of auger filler machine has a unique and capable of dosing and filling works. It is effective by many industries like pharma, agriculture, food, chemical and more. Mostly fluidic or low-fluidity materials, such as coffee powder, wheat flour, condiments, solid drinks, veterinary medications, dextrose, powder additives, talcum powder, pesticides, dyestuff, and more.

Check out the video- https://youtu.be/GyY6hUT8Fac

This auger filler type applies in powder of bottle filling.

Special Features

-A lathing auger screw is used to ensure precise filling.

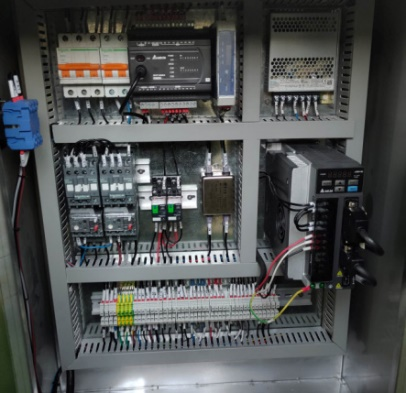

-Display on a touch screen with PLC control.

- The screw is powered by a servo motor to ensure consistent performance.

-The quick-disconnecting hopper can be easily cleaned without any special tools.

-The pedal switch can be set to semi-automatic or automatic filling.

-The material is 304 stainless steels.

- Weight feedback and proportion tracking to materials, able to overcome the challenges of filling weight variations due to material density changes.

- Save 20 formula sets for later use in the machine.

-By replacing the auger pieces, different materials ranging from fine powder to granule and different weights can be packed.

- Interface in multiple languages.

Specification

|

Model |

TP-PF-A10 |

TP-PF-A21 |

TP-PF-A22 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

11L |

25L |

50L |

|

Packing Weight |

1-50g |

1 - 500g |

10 - 5000g |

|

Weight dosing |

By auger |

By auger |

By auger |

|

Packing Accuracy |

≤ 100g, ≤±2% |

≤ 100g, ≤±2%; 100 –500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Filling Speed |

40 – 120 times per min |

40 – 120 times per min |

40 – 120 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

0.84 KW |

1.2 KW |

1.6 KW |

|

Total Weight |

90kg |

160kg |

300kg |

|

Overall Dimensions |

590×560×1070mm |

1500×760×1850mm |

2000×970×2300mm |

Configuration List

|

No. |

Name |

Pro. |

Brand |

|

1 |

PLC |

Taiwan |

DELTA |

|

2 |

Touch Screen |

Taiwan |

DELTA |

|

3 |

Servo motor |

Taiwan |

DELTA |

|

4 |

Servo driver |

Taiwan |

DELTA |

|

5 |

Switching powder |

|

Schneider |

|

6 |

Emergency switch |

|

Schneider |

|

7 |

Contactor |

|

Schneider |

|

8 |

Relay |

|

Omron |

|

9 |

Proximity switch |

Korea |

Au tonics |

|

10 |

Level sensor |

Korea |

Au tonics |

Accessories

|

No. |

Name |

Quantity |

Remark |

|

1 |

Fuse |

10pcs |

|

|

2 |

Jiggle switch |

1pcs |

|

|

3 |

1000g Poise |

1pcs |

|

|

4 |

Socket |

1pcs |

|

|

5 |

Pedal |

1pcs |

|

|

6 |

Connector plug |

3pcs |

Toolbox

|

No. |

Name |

Quantity |

Remark |

|

1 |

Spanner |

2pcs |

|

|

2 |

Spanner |

1set |

|

|

3 |

Slotted screwdriver |

2pcs |

|

|

4 |

Phillips screwdriver |

2pcs |

|

|

5 |

User manual |

1pcs |

|

|

6 |

Packing list |

1pcs |

More Details

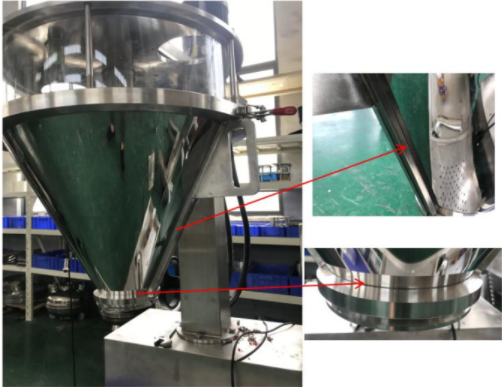

The process is fully welded so it is easy to clean.

If the process is not fully welded, the materials will hide so it’s difficult to clean.

Level Sensor (Au tonics)

When material lever is low it gives signal to the loader, and it feeds automatically.

Hand wheel

It is suitable for filling into bottles/bags with different height.

Leak-proof Acentric Device

It's suitable for filling materials with a lot of fluidity, like salt or white sugar.

Auger screw and Tube

One size screw is suitable for one weight range to ensure filling precision; for example, a diameter 38mm screw is good for filling 100g-250g.

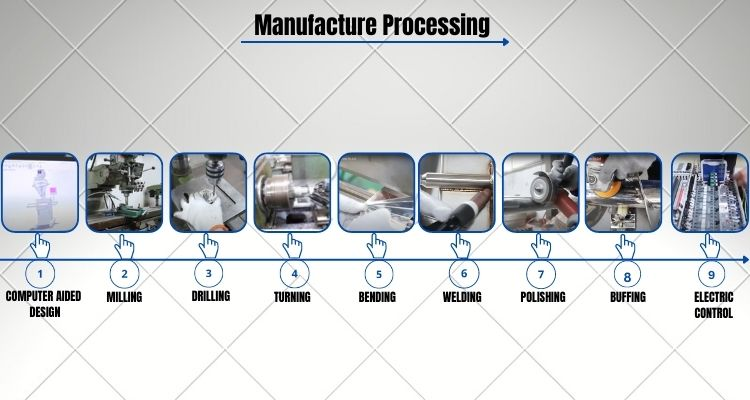

Shanghai Tops Group has a large manufacturing capacity as well as modern auger filler technology. We hold a patent on the appearance of servo auger filler.

Furthermore, on a conventional design, our average production time is approximately 7 days. We may design the auger filler to meet your specific needs. We can manufacture the auger filler according to your specifications, including your logo or company information on the machine label. We also have auger filler components available. We can also use the exact brand if you have object configuration.

Post time: Jan-09-2023