A double-shaft paddle mixer has two shafts with counter-rotating blades that generate two intense upward flows of product, creating a zone of weightlessness with an extreme mixing effect. It is commonly used in the mixing of powder and powder, granular and granular, granular and powder, and a few liquids, particularly those having fragile morphologies that must be maintained.

Main Features:

1. High activity: Rotate backward and release materials from different angles. The mixing time is about 1–3 minutes.

2. High homogeneity: the hopper is filled with a compact design and rotational shafts, resulting in 99 percent mixing uniformity.

3. Low residue: an open-type discharging hole with only 2–5 mm between the shafts and the wall.

4. Zero leakage: A patent-protected design prevents leakage from the revolving axle and discharge hole.

5. Fully Neat and clean: We used a full weld and polishing procedure for the mixing hopper, with no attachment pieces such as screws or nuts.

6. The entire machine, except for the bearing seat, is made entirely of stainless steel, giving it an appealing appearance.

Special Features:

Paddle

This paddle is made of stainless steel, and each angle can hit materials from different directions, resulting in a significant and effective mixing effect.

Full Welded and Polished

The paddle, frame, tank, and other machine components are all entirely welded. The tank's interior is mirror polished, has no dead sections, and is simple to clean.

Round Corner Design

The round corner form adds to the safety of the lid when it is open. The silicone ring makes maintenance and cleaning considerably easier.

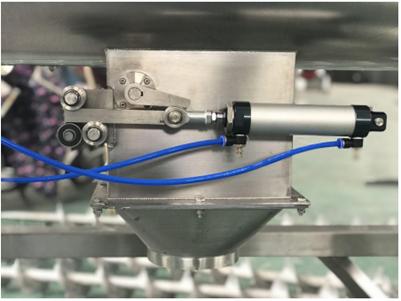

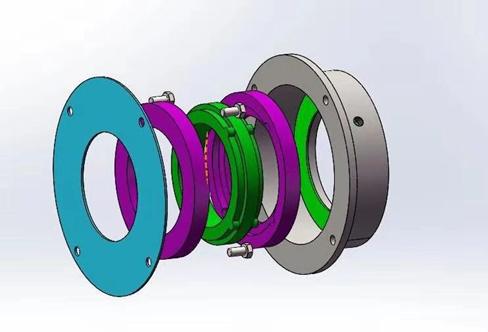

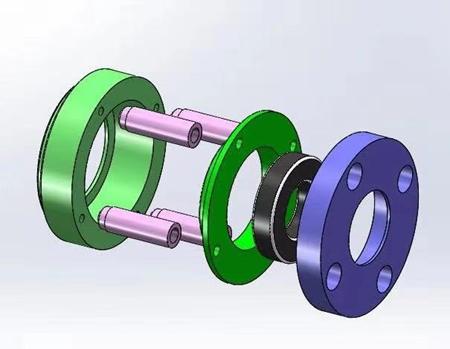

Shaft Sealing

Discharge Hole

There are two discharge hole options: pneumatic discharge and manual discharge. However, a twin-shaft paddle mixer is more convenient to use with pneumatic discharge and has a good quality pneumatic control system, abrasion resistance, and a long life.

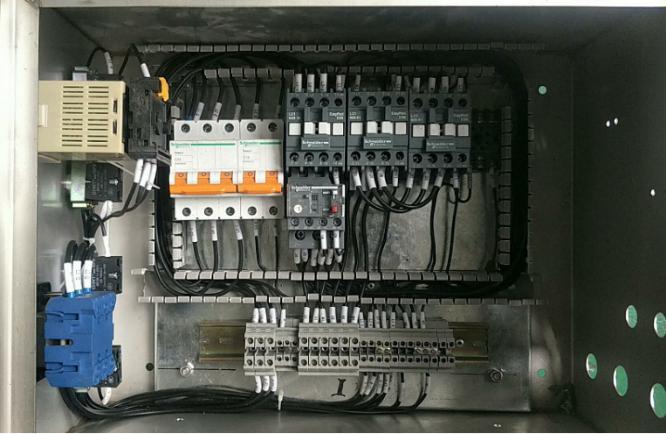

Electronic Box

Schneider & Omron components are used in this electronic box.

Safety Features

Safety Grid

One of the features of a double-shaft paddle mixer is the safety grid. It is made of stainless steel and allows the operator to safely operate the paddle mixer. It also keeps foreign materials from entering the tank.

Safety Switch

When the top cover/lid is opened, the machine comes to a complete halt. The purpose of a safety switch is to protect the operator from harm.

Post time: Jul-25-2022