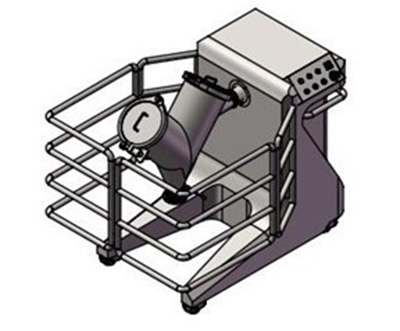

Single-Arm rotary Mixer is an example type of a mixing machine which uses one spinning arm to mix and combine substances. It is recurrently used in research institutions, small production operations and specialized applications that call for a compact and effective mixing solution.

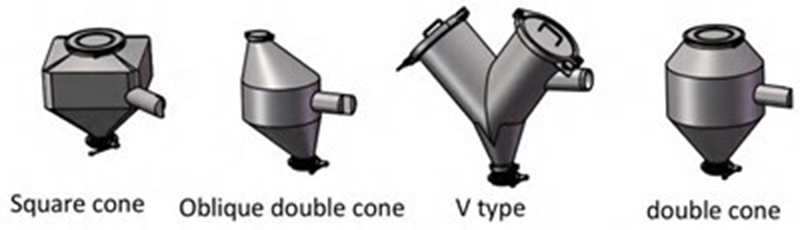

For a variety of mixing requirements, single-arm mixer has the option to switch between tank types (V mixer, double cone, square cone, or oblique double cone) and offers adaptability and versatility.

Functional Concepts:

The mixing tank, frame, transmission, electrical system and other components made up this machine. The gravitational mixing process which causes materials to constantly gather and scatter is dependent on two symmetric cylinders. It takes 5 to 15 minutes to consistently combine two or more granular and powder ingredients. About 40 to 60% of the total mixing volume is the recommended amount to fill the blender. The inner and outer surfaces of the mixing tank are fully welded and polished with precision processing, making them smooth, flat, free of dead angles and simple to clean. This means that the product in the two cylinders moves into the central common area with each turn of the v mixer and this process is continuous.

General Characteristics:

Flexibility and adaptability:

The flexibility and adaptability of a single-arm mixer can be able switch between different tank configurations (V mixer, double cone, square cone, or oblique double cone) and to meet some variety of mixing demands.

Simple maintenance and cleaning:

Through this method, simple maintenance and cleaning of the tanks were created in order to maintain its durability and good performance as well. Consideration should be given to thoroughly inspecting characteristics like removable parts, access panels and smooth, crevice-free surfaces in order to facilitate thorough cleaning and prevent material residue.

Documentation and Training:

Provide users with clear instructions and training materials to guide them through the correct way to operate, how to switch tanks and how to maintain a mixer. By doing this, the machinery will be used more safely and productively.

Motor Speed and Power:

Always check that the motor powering of the mixing arm is big and strong enough to handle the different types of tanks. Think about the varying load requirements and ideal mixing rates for each type of tank.

Moreover, it is cleared as stated above on how to handle carefully this machine and other types of machinery as well. Always seek for help with your friendly technicians and followed by seeking also a copy of your readers manual and asked them for some sort of trainings on how to operate, handle and manage this kind of equipment. As always don’t forget to maintain its cleanliness before and after using.

Post time: Sep-12-2023