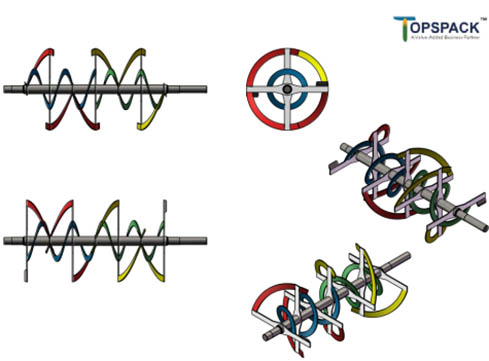

A ribbon mixing machine has different styles of ribbon agitators. The ribbon agitator is made up of inner and outer helical agitators. When moving materials, the inner ribbon moves them from the center to the outside, while the outer ribbon moves them from two sides to the center, and both are coupled with a rotating direction. Ribbon mixing machines take less time to mix while producing a superior result.

Even the tiniest quantity of ingredients can be mixed efficiently with huge volumes, making it ideal for blending powders, powder with liquid, and powder with granule. Ribbon mixing machine is applicable in the construction industry, agricultural chemicals, food, polymers, and medicines, among other applications. Ribbon mixing machines provide flexible and scalable mixing for a more efficient procedure and outcome.

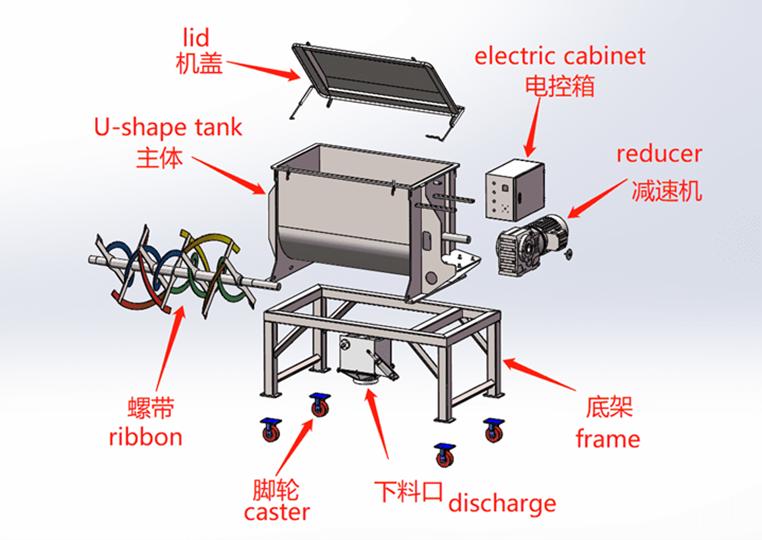

The composition of ribbon mixing machine

The primary characteristics of a ribbon mixing machine are as follows:

- The welds on all connecting parts are excellent.

-The tank’s interior is fully mirrors polished, including the ribbon and shaft.

- Stainless steel 304 is used throughout.

- When mixing, there are no dead angles.

- It has a spherical shape with a silicone ring lid.

- It comes with a secure interlock, a grid, and wheels.

Tops Group has many capacity models ranging from 100L up to 12,000L. We can customize as well if you want a big capacity model.

Post time: Apr-11-2022