Here’s the following steps in using a mixing system:

1. For safe and stable long-term operation,” The High-Efficiency Agitator” must be mounted and utilized properly.

2. To execute the installation, a person/operator must possess the necessary credentials and well-knowledgeable about installing the machinery and equipment.

3. Installation on the high-efficiency mixer must be upright, with no more than a 5-degree vertical deviation.

4. It is strictly prohibited to stir solids and liquids with high viscosities using an efficient stirring mechanism.

5. The motor and bearing cannot run at temperatures below 75°C.

6. Remember that without lubricant, motors, bearings, and gearboxes it can’t function well.

7. This method referring to the bending or distortion, it prevents the agitator shaft and blade from functioning. It should be stopped right away for processing or replacement when the shaft or blade is discovered to be bend.

8. This process pertains to prevent any damage to the mixer shaft; it is strictly prohibited for efficient mixing systems to enter the reaction tank while it is in use.

9. The motor power must be turned off and hung if someone needs to enter the reaction cell for cleaning or maintenance.

Always remember “Do not close” the cautionary sign while there needs to be a specific person working outside the reaction tank when manual tank cleaning and maintenance tasks are being carried out.

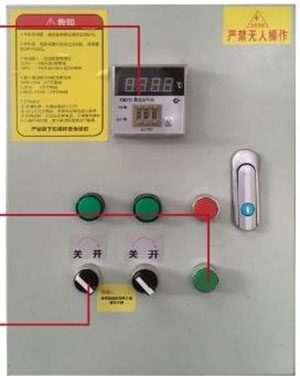

10. Effective operation of the stirring system:

Lastly, If the sediments, pollutants, and debris appear at the bottom of the reaction tank, you must ensure that the mixer is operated safely, it needs to be stopped quickly and cleaned manually or with clean water.

Post time: Aug-14-2023