This Semi-automatic type of auger filler is capable of dosing and filling works. It is used in different industries such as food, pharma, chemical and more. It is a special professional design, which makes it appropriate for fluidic or low-fluidity powder and small granular materials like flour, proteins, flavors, sweetener, condiment, solid coffee powder, formula milk powder, medicines, beverages, veterinary medications, dextrose, talcum powder, agriculture pesticide, dyestuff, and more.

Main Features:

- Perfect filling accuracy - a lathing auger screw is used.

-PLC control and a touch screen display.

- Consistent results - a servo motor powers the screw.

-The split hopper is easily cleaned without used of tools.

- Fully stainless steel 304 that could be configured to semi-auto filling through a pedal switch.

- Weight feedback and proportion track to components, which solves the challenges of filling weight variations owing to density variations in components.

-Save 20 formula settings for subsequent use in the machine.

-Varied materials ranging from fine powder to granule and different weights can be packed by switching the auger pieces.

-Available in many languages.

Specification

|

Model |

TP-PF-A10 |

TP-PF-A11 |

TP-PF-A14 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

11L |

25L |

50L |

|

Packing Weight |

1-50g |

1 - 500g |

10 - 5000g |

|

Weight dosing |

By auger |

By auger |

By auger |

|

Weight Feedback |

By off-line scale (in picture) |

By off-line scale (in picture) |

By off-line scale (in picture) |

|

Packing Accuracy |

≤ 100g, ≤±2% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Filling Speed |

40 – 120 times per min |

40 – 120 times per min |

40 – 120 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

0.84 KW |

0.93 KW |

1.4 KW |

|

Total Weight |

90kg |

160kg |

260kg |

|

Overall Dimensions |

590×560×1070mm |

800×790×1900mm |

1140×970×2200mm |

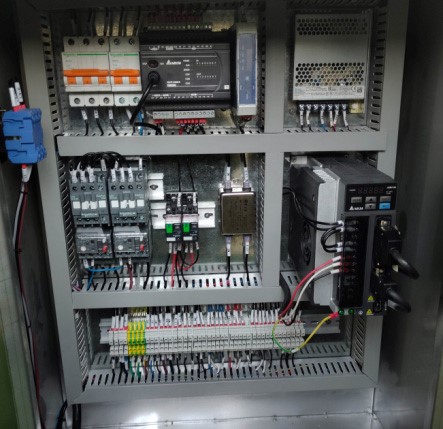

Configuration List

|

No. |

Name |

Pro. |

Brand |

|

1 |

PLC |

Taiwan |

DELTA |

|

2 |

Touch Screen |

Taiwan |

DELTA |

|

3 |

Servo motor |

Taiwan |

DELTA |

|

4 |

Servo driver |

Taiwan |

DELTA |

|

5 |

Switching powder |

|

Schneider |

|

6 |

Emergency switch |

|

Schneider |

|

7 |

Contactor |

|

Schneider |

|

8 |

Relay |

|

omron |

|

9 |

Proximity switch |

Korea |

Autonics |

|

10 |

Level sensor |

Korea |

Autonics |

Accessories

|

No. |

Name |

Quantity |

Remark |

|

1 |

Fuse |

10pcs |

|

|

2 |

Jiggle switch |

1pcs |

|

|

3 |

1000g Poise |

1pcs |

|

|

4 |

Socket |

1pcs |

|

|

5 |

Pedal |

1pcs |

|

|

6 |

Connector plug |

3pcs |

Toolbox

|

No. |

Name |

Quntity |

Remark |

|

1 |

Spanner |

2pcs |

|

|

2 |

Spanner |

1set |

|

|

3 |

Slotted screwdriver |

2pcs |

|

|

4 |

Phillips screwdriver |

2pcs |

|

|

5 |

User manual |

1pcs |

|

|

6 |

Packing list |

1pcs |

Details

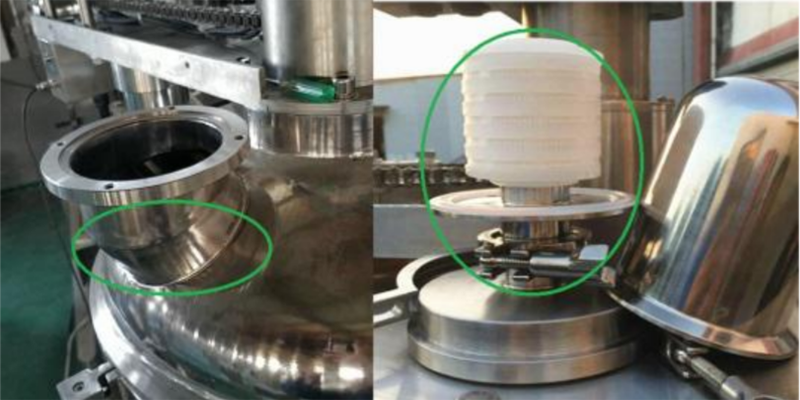

Full SS304 split hopper

It is easy to open and clean.

Level sensor

P+F brand tuning fork type level sensor is more suitable for all types of materials, particularly dusty materials.

Feed inlet & air outlet

The feed inlet has a radian to prevent hopper impact. The air outlet has a quick connection type for easier installation and disassembly.

Height adjusts hand wheel for filling nozzle

It can be used to fill bottles or bags of various heights.

Screw way to fix metering auger in the hopper.

It will not increase the amount of material in stock, and it is not difficult to clean.

Different sizes of metering auger and filling nozzles

It is used for metering different filling weight, and it is fit for container mouth with different diameter.

There is optional device for filler:

Leak-proof acentric device

Connector for dust-collector

Post time: Jan-06-2023