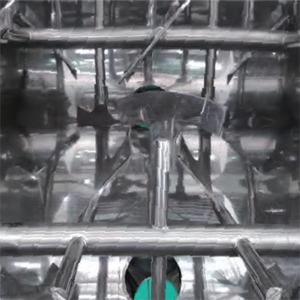

The single-shaft paddle mixer can be used to mix powder and powder, granule and granule, or add a little liquid. It is commonly used with granular materials like almonds, beans and sugar. The machine’s inside has wide-ranging angles of blades that throw up the material, causing cross-mixing.

Those materials are thrown-out from the bottom to the top of the mixing tank by paddles at various angles.

These are the primary qualities of Single-Shaft Paddle Mixer:

A flap dome valve with either pneumatic or manual control and it is located under the tank’s bottom. The valve’s arc design to ensure that no material will build-up and that there will be no dead-angles when mixing. Authentic regular seals prevent the leaking between repeated closes and opens.

Paddles may quickly maintain its original shape while increasing the speed and consistency of the material’s mixing.

The ribbon, shaft, and inside of the mixing tank are all made of stainless steel 304 and are fully mirror polished.

Wheels, a safety switch, and a safety grid for safe and practical use.

Wheels, a safety switch, and a safety grid for safe and practical use.

Teflon rope of the Bergman brand (Germany), with a special design, ensures that the shaft sealing never leaks.

Furthermore, you must know how to operate and manage with this type of machine and know what materials are appropriate to it. To ensure that this machine performs well with durability, you must maintain the checking-cleaning process by means of following and reading the readers manual before and after using. You must know also the importance of what industries are well-suited to this machine as well. Contact the technical support team if problem rises, it is one important factor in maintaining your machine and to longer its lifespan.

Post time: Sep-12-2023