Let's discuss the Shanghai Tops Group China blending machine in today's blog.

There are different types and models of China blending machines developed by Tops Group. Let's find out!

Mini-type Horizontal Mixer

Powder, granules with liquid can all be mixed with it. The ribbon/paddle agitators efficiently mix the ingredients under the usage of a driven motor, achieving a highly efficient and convective mixing in the smallest amount of time. Mostly used in science lab testing; "Machine Dealer Test Material for Customers"; and start-up businesses.

ouble Ribbon Blender (TDPM Series)

In all process industries, it is commonly used to mix different powders, granules with liquid and dry solids mixers. The twin ribbon agitator's unique shape allows the material to quickly achieve a high level of effective convective mixing.

An inner and an outer helical agitator comprise a ribbon agitator. The outer ribbon brings material from the sides to the center and the inner ribbon pushes material from the center to the sides.

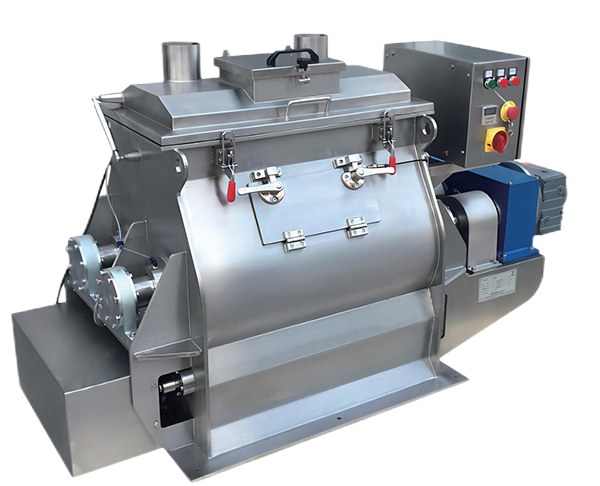

Single Shaft Paddle Mixer (TPS Series)

It works well with powder, granule or add a small amount of liquid to mix. It is frequently used with nuts, beans, flour, and other granule materials; the machine's internal blades are angled differently, which causes the material to be cross-mixed. Paddles at different angles throw material from the bottom to the top of the mixing tank.

Single Shaft Paddle Mixer (TPS Series)

Often used to blend powder, granules and with liquids, this device is often referred to as a gravity-free mixer. Blades push material back and forth for mixing. It is swiftly and evenly mixed and split by the meshing space between the twin shafts.

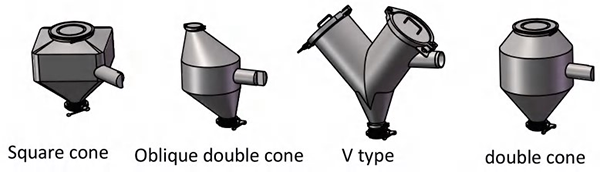

Single-Arm Rotary Mixer (TP-SA Series)

One rotating arm is all that is needed to mix and blend ingredients in a single-arm rotary mixer. It is frequently used in specialty applications that require a small and effective mixing solution, labs, and small-scale manufacturing operations. With the option to switch between tank types (V mixer, double cone, square cone, or oblique double cone) offers flexibility and adaptability.

V Type Mixing Machine (TP-V Series)

Depending on the needs of the user, a forced agitator can be added to make it appropriate for blending materials with a certain moisture content, cake, and fine powder. It is dependent upon the gravitational mixing of two symmetric cylinders, which causes materials to continually accumulate and disperse.

Double Cone Mixing Machine (TP-W Series)

A machine for mixing dry powders and granules that frequently gets used in a variety of industries. Two linked cones make up its mixing drum. An effective way to mix and blend materials is with the double cone type. Free-flowing solids are mostly mixed in proximity using this method.

Vertical Ribbon Blender (TP-VM Series)

The material is raised from the mixer's bottom by the ribbon agitator, which then lets gravity take its course. Furthermore, a chopper is positioned on the vessel's side to break up agglomerates while mixing.

Post time: Aug-02-2024