A ribbon mixer is a widely used industrial mixing machine designed for blending dry powders, granules, and small amounts of liquid additives. It consists of a U-shaped horizontal trough with a helical ribbon agitator that moves materials both radially and laterally, ensuring uniform mixing. Ribbon mixers are commonly used in industries such as food, pharmaceuticals, chemicals, and construction materials. However, like any equipment, they come with both advantages and disadvantages.

Advantages of Ribbon Mixer

Efficient and Uniform Mixing

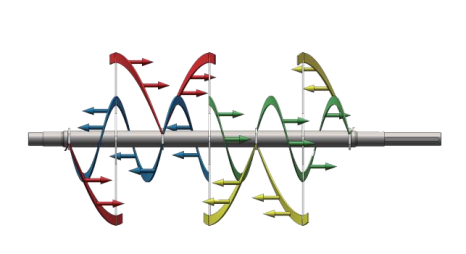

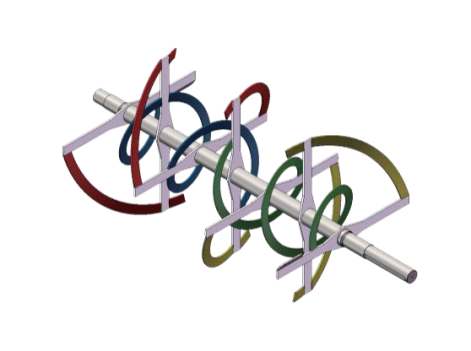

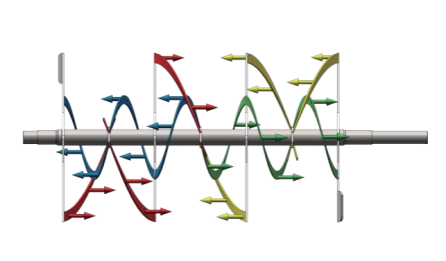

Ribbon mixers are designed to create a balanced counterflow movement, where the outer ribbons move materials in one direction, while the inner ribbons move them in the opposite direction. This ensures a uniform and homogenous blend, making them ideal for dry powders and bulk materials.

Large Batch Capacity

The ribbon mixer is well-suited for large-scale production. With sizes ranging from small laboratory models to large industrial units with thousands of liters of capacity, it can handle bulk material blending efficiently.

Cost-Effective

Due to its simple design and mechanical efficiency, ribbon mixers are relatively cost-effective in terms of both initial investment and maintenance. They require minimal energy consumption compared to high-shear or fluidized bed mixers.

Versatile for Various Applications

Ribbon mixers can handle a wide range of materials, including powders, small granules, and minor liquid additions. They are widely used in industries such as food (spices, flour, protein powder), pharmaceuticals, and chemicals.

Disadvantages of Ribbon Mixer

Mixing Time – Improved with Enhanced Ribbon Design

Traditionally, ribbon mixers have been known to require a longer mixing time compared to high-shear mixers. However, our company has improved the ribbon structure, optimizing the flow pattern to reduce dead zones and enhance mixing efficiency. As a result, our ribbon mixers can complete mixing within 2-10 minutes, significantly improving productivity while maintaining uniformity.

Please check the video: https://youtu.be/9uZH1Ykob6k

Not Ideal for Fragile Materials

Due to the shear force generated by the ribbon blades, fragile materials such as brittle granules or flakes may break down during the mixing process. If preserving the integrity of such materials is essential, a paddle blender or a gentler V-blender may be a better alternative.

Kindly review the video: https://youtu.be/m7GYIq32TQ4

Difficult to Clean – Solved with Full Welding and CIP System

One common concern with ribbon mixers is that their fixed agitators and complex geometry make cleaning more challenging. However, our company has addressed this issue by using full welding and internal polishing, eliminating gaps where residue might accumulate. Additionally, we offer an optional CIP (Clean-in-Place) system, which allows automated washing without the need for disassembly, making cleaning more efficient and convenient.

Normal cleaning video: https://youtu.be/RbS5AccwOZE

CIP system videos:

Heat Generation

The friction between the ribbon and the material can generate heat, which might be problematic for temperature-sensitive powders such as certain food ingredients and chemicals. To counter this, a cooling jacket can be integrated into the mixer’s design, allowing temperature control by circulating water or coolant around the mixing chamber.

Limited Suitability for Sticky or Highly Cohesive Materials

Ribbon mixers are not the best choice for highly sticky or cohesive materials, as these can adhere to the mixing surfaces, reducing efficiency and making cleaning more difficult. For such applications, a paddle blender or plow mixer with specialized coatings may be more effective.

While ribbon mixers have some inherent limitations, continuous improvements in design, such as optimized ribbon structure, full welding, and CIP systems, have significantly enhanced their efficiency and ease of use. They remain an excellent choice for large-scale, cost-effective, and uniform blending of powders and granules. However, for fragile, sticky, or heat-sensitive materials, alternative mixing technologies might be more suitable. If you have any specific mixing requirements, feel free to contact us for expert guidance and customized solutions.

Post time: Mar-28-2025