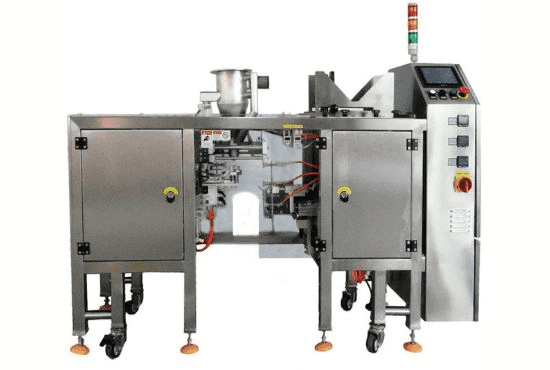

What is an Automatic Pouch Packing Machine?

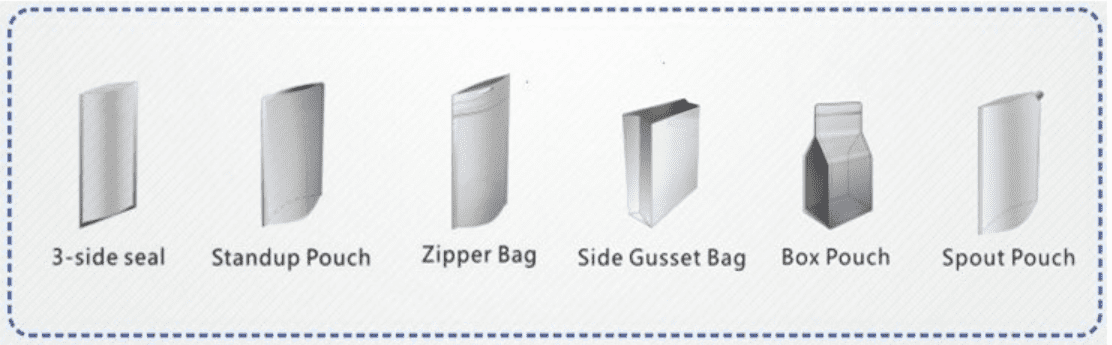

A fully automatic pouch packing machine can perform functions such as bag opening, zipper opening, filling, and heat sealing. It can take up less space. It's simple to clean and maintain. It is applied in many industries, including food, chemicals, pharmaceuticals, and others.

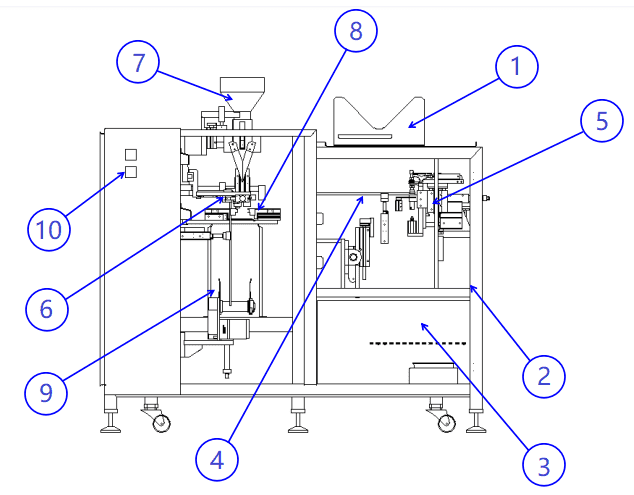

Structure:

| 1 | bag holder | 6 | open the bag |

| 2 | frame | 7 | filling hopper |

| 3 | Electric box | 8 | heat seal |

| 4 | take the bag | 9 | Finished product delivery |

| 5 | zipper opening device | 10 | Temperature Controller |

What are the Optional Features?

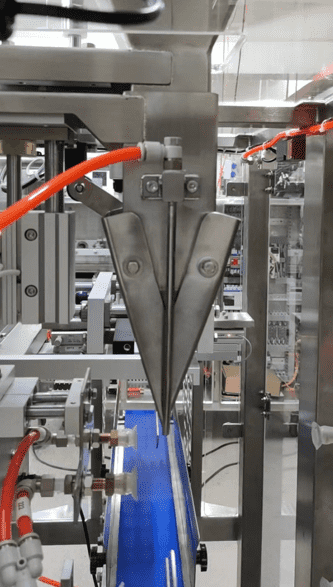

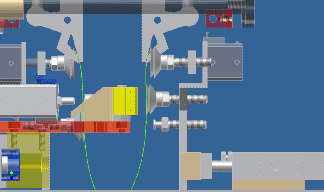

1.Zipper-opening device

The zipper must be at least 30mm from the top of the pouch/bag to be opened.

The minimum bag width is 120mm; otherwise, the zipper device will meet two small air cylinders and will be unable to open the zipper.

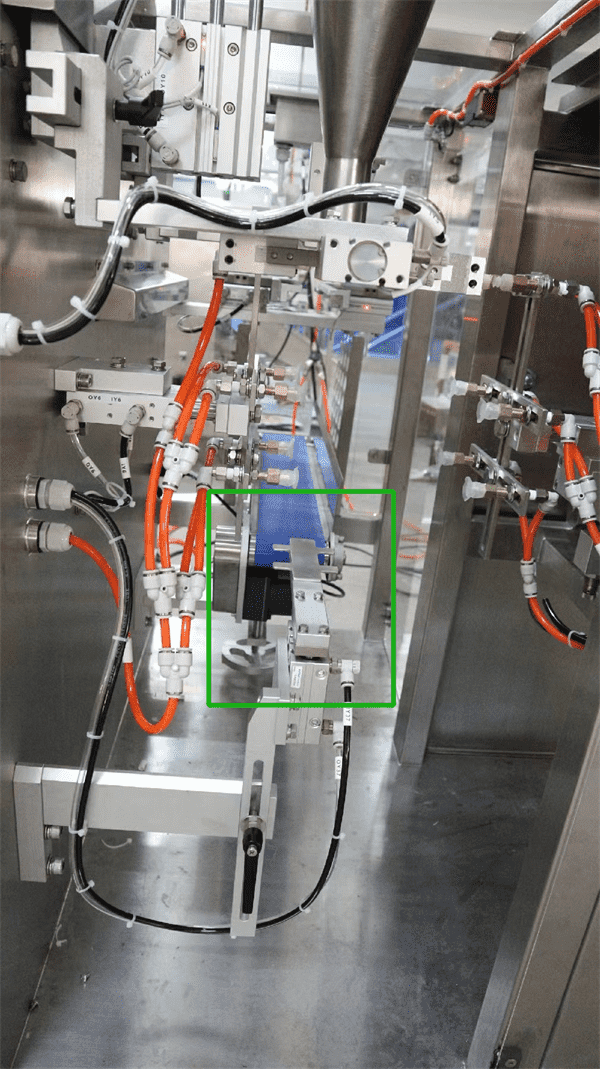

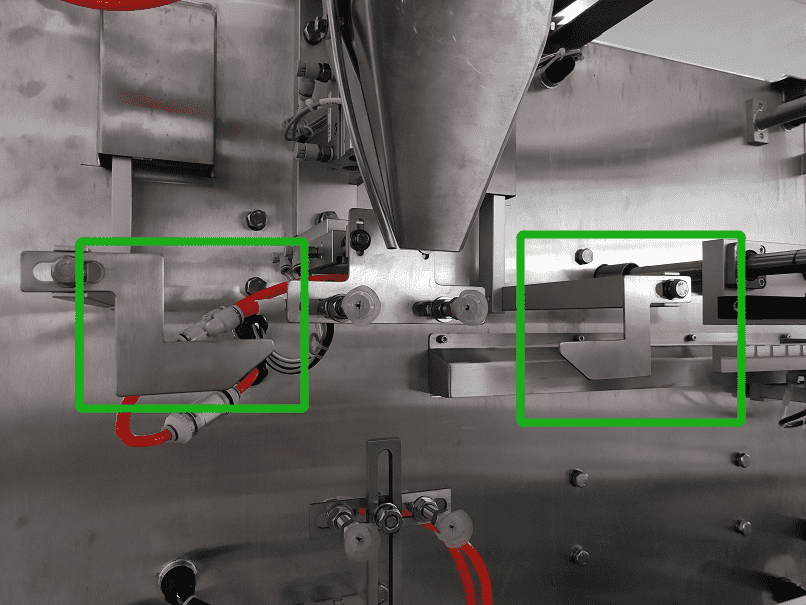

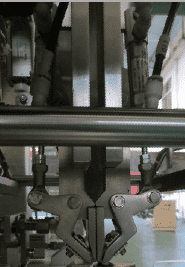

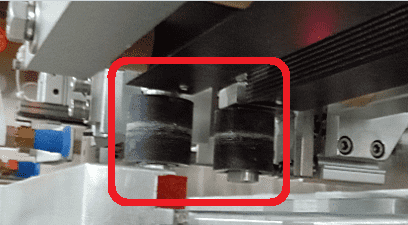

2. Zipper sealing device

*In the vicinity of the filling station and the sealing station. Close the zipper after filling before heat sealing. Avoid powder accumulation on the zipper while using powder products.

*As seen in the image below, the filled bag closes the zipper with the roller.

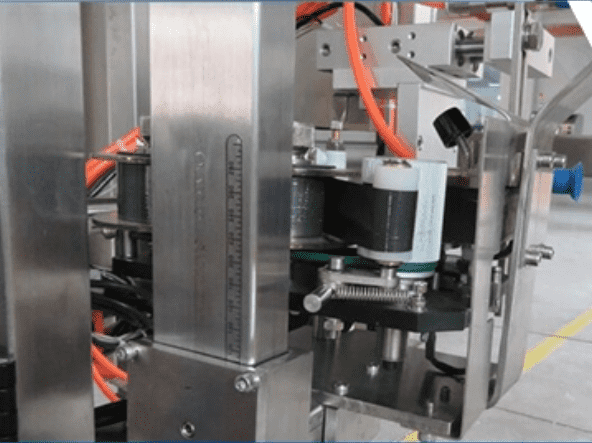

3.Tote bag

Effect:

1) When filling, hold the bottom of the bag and use the vibration feature to let the material fall uniformly to the bottom of the bag.

2) Because the clip's weight is limited, the bottom of the bag must be held to keep the material from becoming too heavy and slipping off the clip while filling.

Customers are advised to include a carrier bag device in the following situations:

1) Weight greater than 1 kilogram

2) Powder material

3) The packaging bag is a prong bag, which allows the material to fill the bottom of the bag quickly and neatly by tapping.

4.Coding machine

5.Nitrogen-filled

5.Nitrogen-filled

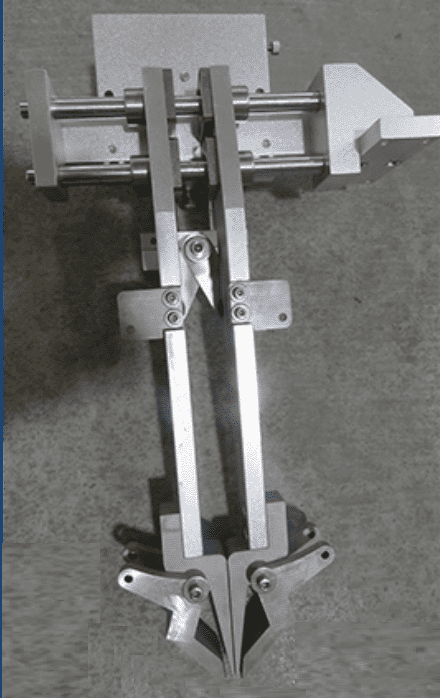

6.Gusseted device

The machine must be equipped with a gusset mechanism to produce gusset bags.

Application:

It can pack powder, granular, and liquid materials and is equipped with various measuring equipment.

Post time: Jun-27-2022