Industrial blenders are essential for mixing powders, granules, and other materials in industries such as food, pharmaceuticals, and chemicals. Among the various types, Ribbon Blenders, Paddle Blenders, and V-Blenders (or Double Cone Blenders) are the most common. Each type has unique characteristics and is suited for specific applications. This article provides a comparison of these blenders and guides you on how to choose the right one.

Types of Blenders

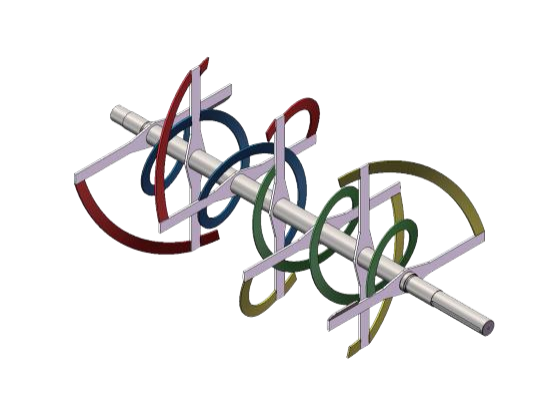

1 Ribbon Blender

Ribbon blenders consist of a horizontal U-shaped trough and a helical ribbon agitator. The inner and outer ribbons move materials in opposite directions, ensuring uniform mixing.

- Best for: Dry powders, formulations with uniform particle size and density.

- Not suitable for: Fragile materials, materials with high viscosity or requiring gentle mixing.

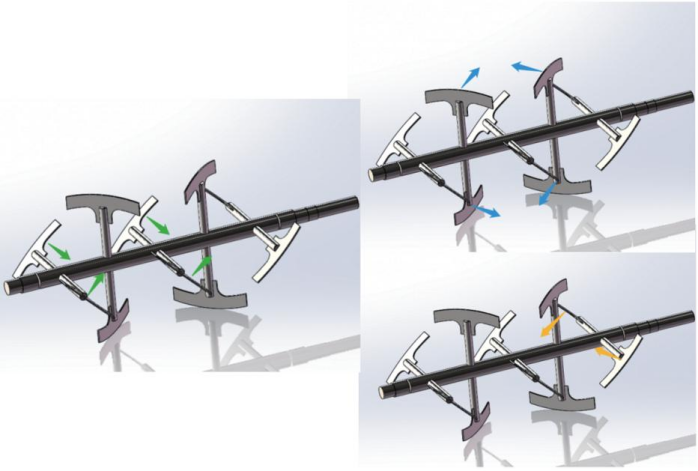

2 Paddle Blender

Paddle blenders have large paddles that move materials in multiple directions, making them ideal for handling diverse materials.

- Best for: Fragile materials, sticky or viscous ingredients, and blends with significant density differences.

- Not suitable for: Simple homogeneous powders that require fast mixing.

3 V-Blender & Double Cone Blender

These blenders use a tumbling motion to mix materials gently. They have no agitators, making them ideal for fragile and free-flowing powders.

- Best for: Fragile materials, gentle blending, and pre-mixing.

- Not suitable for: Sticky or high-density materials requiring high shear force.

Comparison of Mixing Principles

|

Blender Type |

Mixing Principle |

Best For |

Not Suitable For |

| Ribbon Blender | Dual-direction ribbon movement creates shear and convective mixing. | Dry powders, uniform formulations. | Fragile or sticky materials. |

| Paddle Blender | Paddles lift and fold material, ensuring gentle and uniform mixing. | Fragile, sticky, and varying-density materials. | Simple, homogeneous powders. |

| V-Blender/Double Cone Blender | Tumbling action with no internal agitation. | Delicate materials needing gentle mixing. | High-shear or sticky materials. |

How to Choose the Right Blender

Selecting the right blender depends on multiple factors, including material properties and mixing requirements.

1. Identify Your Material Characteristics

Powder Type: Is the material free-flowing, cohesive, or fragile?

Density Difference: Does the blend contain ingredients with large density variations?

Shear Sensitivity: Can the material withstand high mechanical force?

Moisture & Stickiness: Does the material tend to clump or stick to surfaces?

Mixing Intensity:High-shear, fast blending → Ribbon Blender

Gentle, low-shear blending → V-Blender/Double Cone Blender

Controlled mixing for fragile/dense materials → Paddle Blender

Mixing Uniformity:Simple homogeneous powders → Ribbon Blender

Complex blends with different densities → Paddle Blender

Gentle pre-mixing → V-Blender/Double Cone Blender

Batch Size & Production Scale:

Small lab-scale/pilot batches → V-Blender/Double Cone Blender

Large-scale production → Ribbon or Paddle Blender

2. Determine Your Mixing Requirements

Understanding the differences in blender types and their applications helps ensure efficient and effective mixing for your specific needs. By analyzing material properties and mixing requirements, you can select the most suitable blender for optimal performance. If you have any questions, please contact us, and we will respond to you within 24 hours free of charge.

Post time: Mar-28-2025