A tumbling mixer is a type of industrial mixer commonly used in various industries for blending bulk powders, granules, and other dry materials. As the name suggests, the tumbling mixer uses a rotating drum or container to mix materials, relying on the tumbling action to achieve uniform mixing. Tumbling mixers are highly valued for their simplicity, effectiveness, and versatility, making them a popular choice for many applications.

How Does a Tumbling Mixer Work?

A tumbling mixer consists of a cylindrical or conical container that rotates around a central axis. Inside this container, the materials are placed and subjected to a tumbling motion as the container rotates. The materials move through the mixer in a series of rolling and cascading motions, which helps break up lumps, reduce segregation, and ensure an even mix. The rotating action allows the materials to combine without applying excessive shear forces, which is particularly beneficial for fragile or sensitive materials.

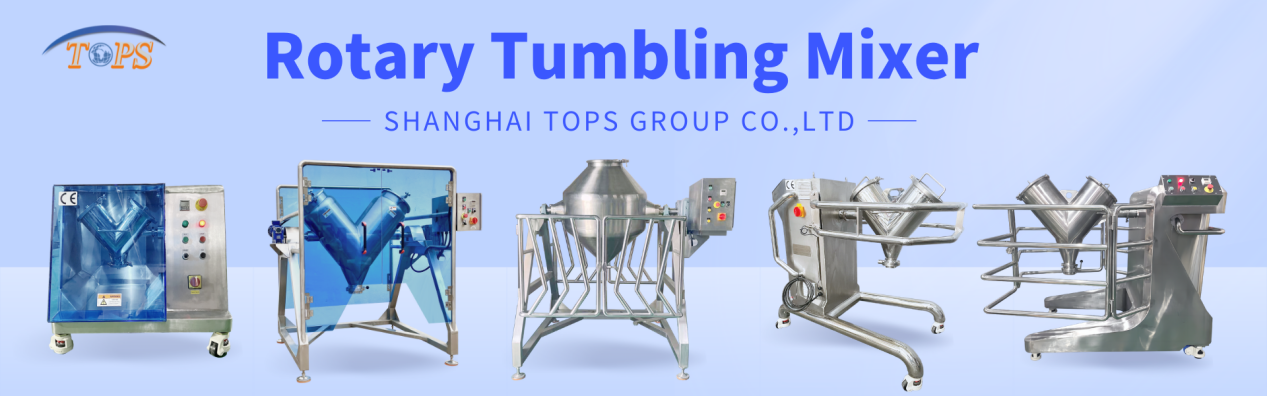

Types of Tumbling Mixers

Tumbling mixers come in various designs, with the most common types being:

Rotary Drum Mixers: The most straightforward form of a tumbling mixer, rotary drum mixers are often used for large-scale applications. The materials are placed into a rotating drum, and the gentle tumbling action ensures uniform blending. Rotary drum mixers are commonly used in industries like mining, agriculture, and food processing.

V-Blenders: These are a variation of tumbling mixers that use two cylinders arranged in the shape of a "V." The materials tumble as they move between the two cylinders, which ensures thorough mixing. V-blenders are often used for smaller batches or more delicate materials, including powders and granules.

Double Cone Mixers: These tumbling mixers consist of two conical sections that rotate, allowing the materials to be gently mixed as they tumble from one cone to the other. Double cone mixers are commonly used in pharmaceuticals and chemicals, where uniformity and gentle mixing are critical.

Applications of Tumbling Mixers

Tumbling mixers are widely used across various industries for both small and large-scale production processes. Some common applications include:

Tumbling mixers are a valuable tool in many industries due to their simplicity, energy efficiency, and gentle mixing action. While they may not be the fastest option for some applications, their ability to handle fragile and sensitive materials makes them an ideal choice in many situations. By understanding the benefits and limitations of tumbling mixers, businesses can select the right equipment for their specific mixing needs, ensuring consistent product quality and efficient production processes.

Contact us, and we will respond within 24 hours, providing you with a free, professional mixing solution.

Post time: Apr-16-2025