In today's article, we will talk about the types of filling machines that work well with bottle powder filling machines.

More than 20 years have passed since Shanghai Tops Group began manufacturing machinery. Design, manufacture, support, and servicing are our areas of expertise. The above type can fill bottles with powder in large amounts. The fluidic or low-fluidity materials are appropriate for it because of its unique professional design.

The bottle powder filling machine can be equipped with either an automatic or semi-automatic type, and it can switch between the two flexible types simultaneously.

You can select from the following types of filling machines to fill bottles:

Tabletop type Standard type High level type

The low-speed filling is appropriate for the semi-auto filling since the operator must manually fill the bottles, set them on a plate beneath the filler, and then remove the bottles. There is a complete stainless-steel alternative for the hopper. Additionally, between a tuning fork sensor and a photoelectric sensor, the sensor can be selected. We provide regular and high-level model auger filler for powder, as well as mini auger filler.

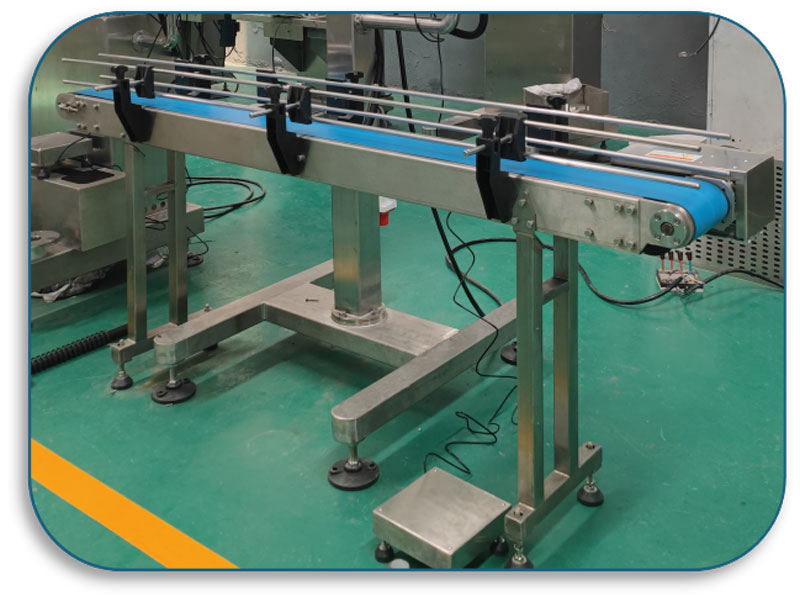

For filling powder bottles, an automated filling with a line design is used. To set up an automated packaging line, it can be linked to a labeling machine, capping machine, powder feeder, and powder mixer. Bottles are brought in by the conveyor, and the stopper keeps bottles back so the bottle holder may lift the bottle beneath the filler. The bottles are automatically filled and then moved forward by the conveyor. It is appropriate for users who have several packaging dimensions and can handle various bottle sizes on a single machine.

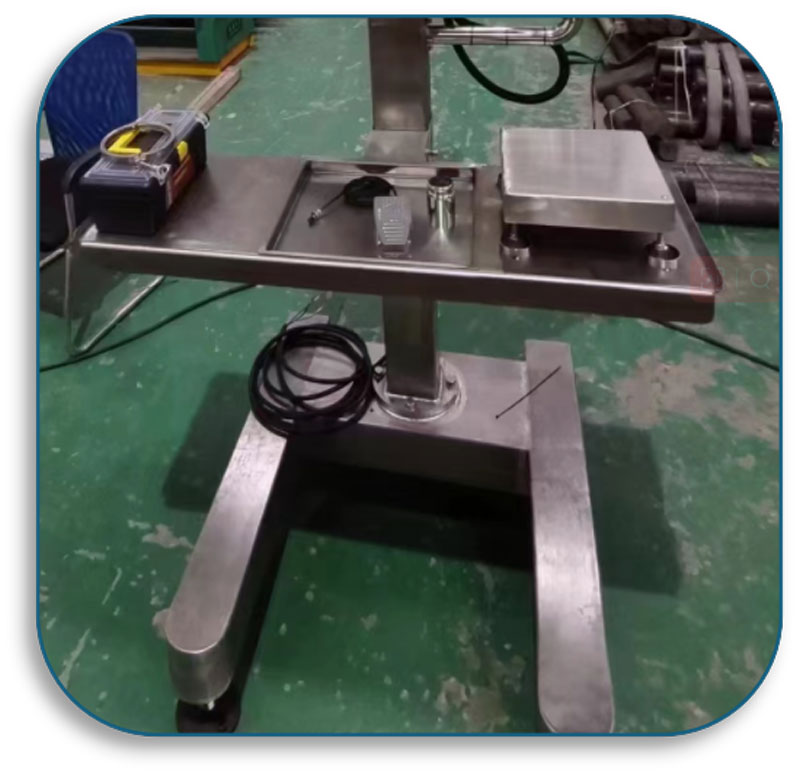

The powder is quickly filled into bottles using a rotary filling. Because the bottle wheel can only accommodate one diameter, this type of auger filler is appropriate for customers with bottles that are just one or two diameter sizes. Nonetheless, compared to line-type auger filler, the accuracy and speed are superior. Furthermore, the rotary type features an online rejection and weighing function. The rejection function will identify and eliminate unqualified weight, and the filler will fill the powder by the filling weight in real-time.

With a 4-head auger filler, the dosing and filling machine is a compact type that fills four times quicker than one auger head. The requirements of a manufacturing line can be met by this machine. It is managed via a centralized system. There are two filling heads in each lane, each of which can do two separate fills. A horizontal screw conveyor with two exits would be used to feed materials into the two auger hoppers.

Post time: Jul-19-2024