China screw conveyor is a form of mechanical conveying system that moves items alongside the cylindrical casing using a revolving helical screw blade known as an auger. It is often applied in the agricultural, food processing, and manufacturing industries.

Specification:

| Main Specification | HZ-2A2 | HZ-2A3 | HZ-2A5 |

HZ-2A7 |

HZ-2A8 |

HZ-2A12 |

| Charging Capacity | 2m³/h | 3m³/h | 5m³/h | 7m³/h | 8m³/h | 12m³/h |

| Diameter of pipe | Φ102 | Φ114 | Φ141 | Φ159 | Φ168 | Φ219 |

| Hopper Volume | 100L | 200L | 200L | 200L | 200L | 200L |

| Power Supply | 3P AC208-415V 50/60HZ | |||||

|

Total Power |

610W |

810W |

1560W |

2260W |

3060W |

4060W |

|

Total Weight |

100kg |

130Kg |

170Kg |

200Kg |

220Kg |

270Kg |

| Overall Dimensions of Hopper | 720×620×800mm | 1023×820×900mm | ||||

| Charging Height |

Standard 1.85M,1-5M could be designed and manufactured |

|||||

| Charging angle |

Standard 45-degree ,30-60 degree is also available |

|||||

These are the China screw conveyor essential components and as follows:

Screw:

The conveyor's central component is consisting of a helical flighting wrapped around the central shaft. The screw is in-charge of all moving materials inside on it.

Casing:

It is a cylindrical tube that surrounds and holds the materials being delivered. It provides material support and containment

The power source that rotates the screw is known as the drive unit. It could be a motor, a hydraulic motor, or another sort of mechanical drive.

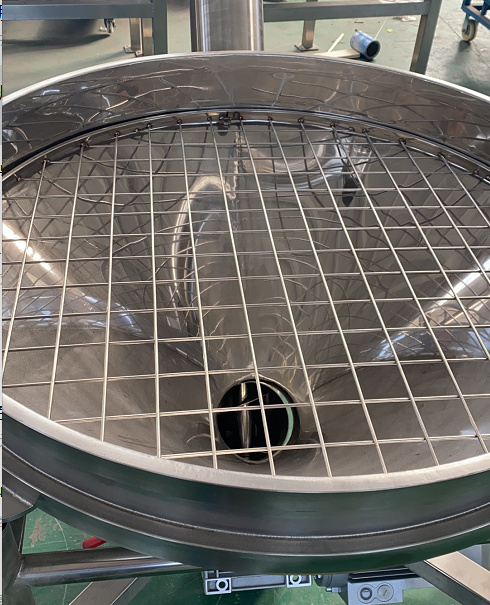

There are two types of hoppers: round and square.

Inlet and outlet:

The openings at the conveyor's ends allows the materials to enter and departs the system.

China screw conveyor operation is easy. The materials are carried alongside screw's trough as it revolves. The rotation of the screw produces “a pushing or pulling motion” that drives the materials forward and depending on its design. Depending on the use, the screw might be slanted or vertical.

China screw conveyor are adaptable and can handle a variety of materials, including powders, granules, flakes, and even semi-solids. They are utilized of some variation of tasks, including transporting materials, mixing, and batching. The screw conveyor's design can be customized as to specific material qualities, throughput requirements, and operational conditions.

Post time: May-09-2024