For today's blog, let's talk about the powder weighing and filling machine. Let's have a brief description of this machine. Let's find out!

Function of a powder weighing and filling machine

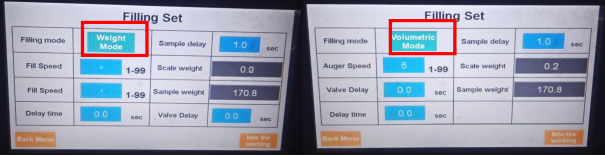

A powder weighing and filling machine is commonly used for dosing powders and granular materials. There are two types of weighing modes: weight mode and volume mode. It's simple to move between the two.

The Filling Mode:

Mode of Volume

Switching between the weight and volume modes is easy.

The powder volume is decreased with a single turn of the screw. The number of spins the screw has to do to reach the required fill weight will be determined by the control system.

Mode of Weight

To measure the filling weight in real-time, a load cell is placed under the filling plate. Eighty percent of the goal filling weight is achieved in a rapid and substantial initial filling. A little more slowly and precisely, the second filling adds the final 20% of the filling weighted down from the first. Although weight mode takes a little longer, it is more accurate.

Function of automatic and semi-automatic:

Automatic powder weighing and filling machine

Automatic lines are efficient for filling and dosing. For the bottle holder to raise the bottles under the filler, the bottle stopper holds the bottles back. They can be automatically moved in by the conveyor.

The conveyor advances the bottles automatically once they are filled. Because it can accommodate different bottle sizes on a single machine, it is perfect for users with diverse packaging dimensions.

Semi-Automatic powder weighing and filling machine

A semi-automatic powder filler is used for both dosing and filling. The manual method involves putting the bottle or pouch on the plate underneath the filling and taking it out once the filling is complete. To guarantee exact filling precision, it makes use of a lathing auger screw.

Post time: May-28-2024